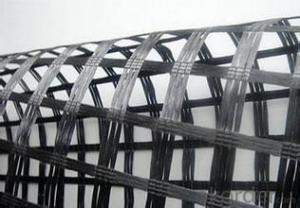

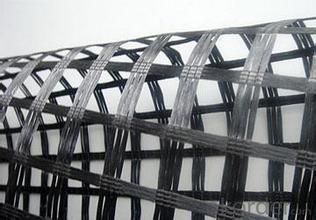

Naue Biaxial Uniaxial Bitumen Coated Black Fiberglass Geogrids

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Description

Fiberglass Geogrid is widely used in civil construction over the whole world. It is manufactured on the basis of high-impact fiberglass.

Fiberglass Geogrid are used as reinforcement materials on mellow soils for railway and car roads, parking places, landing grounds and for the reinforcement of bridge piers, slopes and earth banks, for erosion protection of slopes.

Overall features & benefits

High tensile strength in both the warp and weft directions;

Low elongation;

Good anti-age and alkali-resistance;

Reduce construction cost, extend service life of road and prevent deflection cracks.

Specification

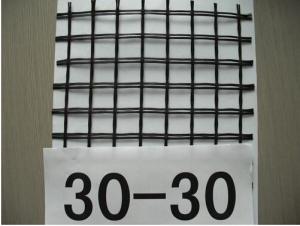

Intensity: 25, 30,40,50,80,100 KN/M

Width: 1-6M Length: 50-100 M

Application

Reinforcement of highways slopes and higher steepness slopes fixation;

Bed fixation of the various types of road surfacing;

Reinforcement of littoral zone of water reservoirs and Greek beds;

Fixation of the railroad cone slopes;

Support wall construction.

Packaging & Delivery

| Packaging Details: | Rolls |

| Delivery Detail: | 20 Days |

Detiled Data

Tensile | Warp | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥120 |

Strength | |||||||

(KN) | Weft | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥120 |

Elogation | Fiberglass | <4 % | 4 % | 4 % | 4 % | 4 % | 4 % |

Polyester | <13%< span=""> | 13% | 13% | 13% | 13% | 13% | |

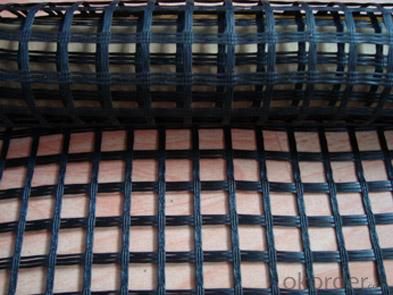

Mesh size(mm) | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | |

25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | ||

42×42 | 42×42 | 42×42 | 42×42 | 42×42 | 42×42 | ||

50×50 | 50×50 | 50×50 | 50×50 | 50×50 | 50×50 | ||

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | |

(Fiberglass) | |||||||

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature | Fiberglass | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 |

Resistant (°C) | Polyester | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 |

Resin | Fiberglass | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 |

Content (%) | polyester | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% |

F&Q

1 How about the delivery time? Lead time since receipt of 30% T/T deposit payment: 3 weeks.2 What kind of payments does jenor support? T/T 3

What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4

How to deal with the sample charge?

Accordeing to our company policy, the samples are free, we only charge the freight fee.

And we will return the freight fee If you set the order .

5

Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6

Can you tell me your main customers?

That's our customers' privacy, we should protect their information.

At the same time, please rest assured that your information is also safe here.

- Q: How much is a square grille

- To see what kind of model 3.3----------5.8----------------15 yuan

- Q: How to distinguish from the appearance of plastic geogrid and fiberglass geogrid

- Appearance difference is obvious,

- Q: How do geogrids improve the performance of geocellular systems?

- Geogrids improve the performance of geocellular systems by providing reinforcement and structural stability. They help distribute load evenly, prevent lateral movement of soil, and enhance the overall strength of the system. Additionally, geogrids increase the bearing capacity of the geocells, reduce soil settlement, and improve drainage, thereby optimizing the performance and longevity of the geocellular system.

- Q: What is high strength geogrid

- High strength geogrid grille is actually refers to the large geogrid,

- Q: What are the benefits of using geogrids in roadways?

- The benefits of using geogrids in roadways include improved load-bearing capacity, reduced pavement thickness, increased stability and durability, prevention of cracking and rutting, enhanced drainage and erosion control, and cost savings in construction and maintenance.

- Q: Water conservancy projects, the construction of the geogrid used in the quota which is not, how should the set of fixed price calculation of geogrid?

- The measurement of municipal geogrid shall not be included in the overlap area

- Q: Are geogrids suitable for use in high-traffic areas?

- Yes, geogrids are suitable for use in high-traffic areas. Geogrids are specifically designed to provide reinforcement and stability to soils and aggregate materials. They are capable of distributing load forces and reducing deformation, making them ideal for high-traffic areas such as roadways, parking lots, and industrial yards. Geogrids enhance the durability and lifespan of these surfaces, ensuring they can withstand heavy traffic loads without significant deterioration.

- Q: How do geogrids improve the performance of geocells?

- Geogrids enhance the performance of geocells by providing reinforcement and stability to the structure. They help distribute the load evenly, prevent lateral spreading, and increase the overall strength of the geocell system. Additionally, geogrids reduce the potential for soil erosion and improve the long-term durability of the geocell installation.

- Q: Can geogrids be used in temporary construction haul roads for mining applications?

- Yes, geogrids can be used in temporary construction haul roads for mining applications. Geogrids are a type of geosynthetic material that can provide stabilization and reinforcement to the road base, increasing its load-bearing capacity and reducing the risk of erosion and rutting. They are commonly used in mining applications to improve the performance and longevity of haul roads, even in temporary construction scenarios.

- Q: What are the different types of geogrids?

- There are several different types of geogrids, including biaxial geogrids, uniaxial geogrids, and triaxial geogrids. Biaxial geogrids have strength in two directions and are commonly used for soil stabilization and reinforcement. Uniaxial geogrids have strength in one direction and are often used for retaining walls and steep slopes. Triaxial geogrids have strength in three directions and are primarily used for load-bearing applications such as road construction and pavement reinforcement.

Send your message to us

Naue Biaxial Uniaxial Bitumen Coated Black Fiberglass Geogrids

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords