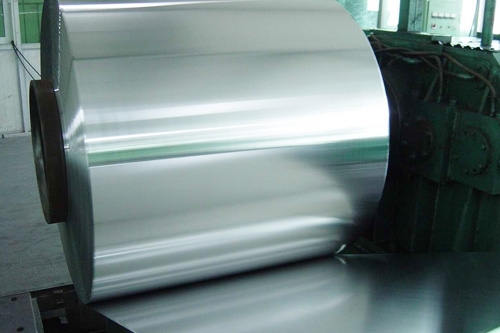

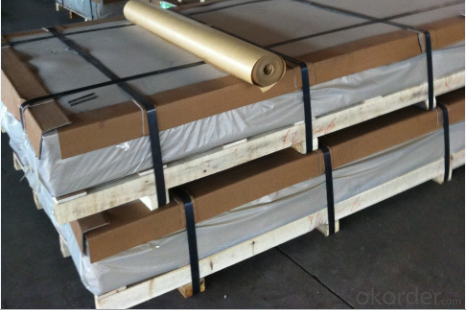

Natural Aluminum Baking Sheets - Aluminum Sheet and Plate Stocks in Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

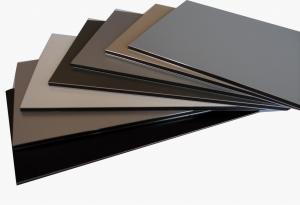

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Can aluminum sheets be used for packaging purposes?

- Yes, aluminum sheets can be used for packaging purposes. They are commonly used in the packaging industry due to their lightweight, corrosion-resistant, and malleable properties. Aluminum sheets can be easily formed into various shapes and sizes, making them ideal for packaging products such as food, beverages, pharmaceuticals, and cosmetics. Additionally, aluminum provides a protective barrier against moisture, oxygen, and light, ensuring the quality and longevity of the packaged goods.

- Q: Can aluminum sheet be used for food contact applications?

- Yes, aluminum sheet can be used for food contact applications. Aluminum is a widely used material in the food industry due to its excellent properties. It is non-toxic, corrosion-resistant, and has a high thermal conductivity, making it suitable for various food processing and packaging applications. Aluminum sheets can be used to make food containers, trays, and foils, providing a safe and hygienic option for food storage and transportation. Additionally, aluminum is recyclable, making it an environmentally friendly choice for food contact applications.

- Q: Are the aluminum sheets suitable for manufacturing electronic enclosures?

- Yes, aluminum sheets are suitable for manufacturing electronic enclosures. Aluminum is a popular choice for electronic enclosures due to its excellent combination of strength, durability, and lightweight properties. It offers good electrical conductivity, making it suitable for dissipating heat generated by electronic components. Additionally, aluminum sheets can be easily shaped, formed, and machined to meet the specific requirements of electronic enclosures, allowing for customization and flexibility in design. Its corrosion resistance properties also make it suitable for protecting electronic devices from environmental factors. Overall, aluminum sheets provide an ideal material solution for manufacturing electronic enclosures.

- Q: can the oxide film on the surface of aluminum sheet prevent the erosion of acid liquid? Why?

- yes, acid can react with aluminum oxide , generating salt and water, but its anti-corrosion will be stronger if oxide film on the surface is enough dense.

- Q: Is aluminum a metal or a non-metal?

- Aluminum is a metal.

- Q: HI! I have a few of my most favorite aluminum baking pans and lids that are brown with baked on grease etc...and I have not the strength or endurance to stand and buff them with a scratchy pad til they gleam....are there any cleaning chems or soaps that will do this for me?? Thanks!! Mama never told me there'd be days like this!

- Thanks, have all of the above that you mentioned...just that a few are favorites as I can pick them up easily - bad shoulders and elbows have weight bearing issues....I don't even cook all that much, but seem to burn a lot - even when boiling eggs....it is a miserable commentary on a day in the life of Aunt Susie....

- Q: Is the value of specific heat capacity of aluminium higher or lower than the standard value? Why?

- RE: Specific heat capacity of aluminium...? Is the value of specific heat capacity of aluminium higher or lower than the standard value? Why?

- Q: How do aluminum sheets perform in terms of water resistance?

- Aluminum sheets have excellent water resistance properties. Due to the natural oxide layer that forms on its surface, aluminum is highly resistant to corrosion and effectively prevents the penetration of water. This oxide layer, also known as aluminum oxide, acts as a protective barrier, inhibiting the reaction between aluminum and water molecules. Additionally, aluminum sheets can be further enhanced with different surface treatments, such as anodizing or coating, to improve their water resistance even further. These treatments create a thicker and more durable oxide layer, making the aluminum sheets highly resistant to water damage, moisture, and rust. Overall, aluminum sheets are a reliable choice for applications that require water resistance, ensuring long-lasting performance in various environments.

- Q: This question asks for a list of adhesive types that are suitable for bonding aluminum sheets. It is important to provide a variety of options to give a comprehensive answer.

- <p>There are several types of adhesives used for bonding aluminum sheets together, including epoxy resins, which offer strong adhesion and resistance to heat and chemicals; polyurethane adhesives, known for their flexibility and durability; acrylic adhesives, which provide good adhesion and are easy to use; cyanoacrylates or 'super glues,' which bond quickly and are great for small, precise applications; and silicone adhesives, which are excellent for high-temperature applications and offer flexibility. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, and resistance to environmental factors.</p>

- Q: How do aluminum sheets perform in terms of machinability?

- Aluminum sheets are known for their excellent machinability. They can be easily cut, drilled, and shaped using various machining processes. The softness and low melting point of aluminum make it highly conducive to machining operations. Additionally, aluminum sheets exhibit good chip formation and evacuation, resulting in smooth and efficient machining.

Send your message to us

Natural Aluminum Baking Sheets - Aluminum Sheet and Plate Stocks in Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords