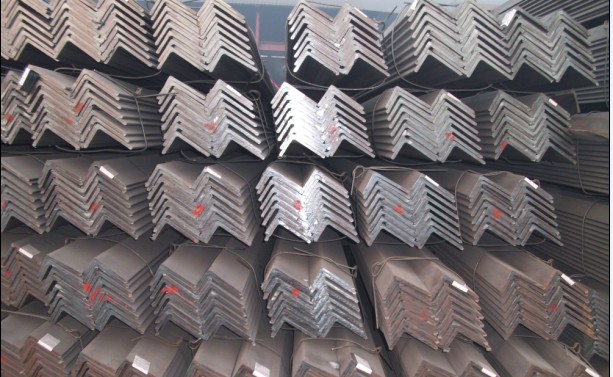

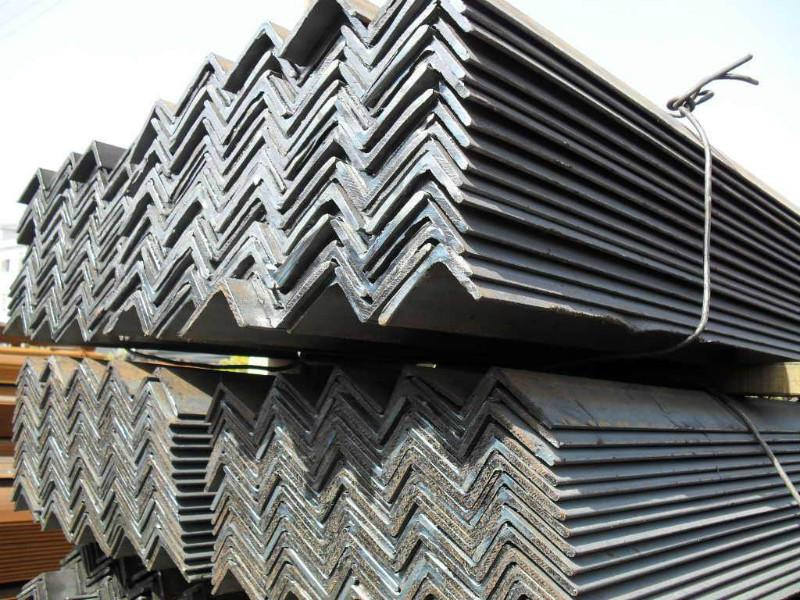

MS equal/unequal black & galvanized steel angle bar with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Hot rolled carbon steel angle bar

Prompt delivery,Premium quality

Accept customized sizes

Accept client's LOGO

Mild steel angle bars OR Low content alloy angle bars | |

| Size | 25mm*25mm-250mm*250mm |

Wall thickness | 1.5mm-25mm |

Length | 1m-12m ,by customer’s requiremnts |

Internatioanal Standard | ISO 9001-2008 |

Standards |

ASTMA53/ASTM A573/ASTM A283/Gr.D/

BS1387-1985/

GB/T3091-2001,GB/T13793-92, ISO630/E235B/

JIS G3101/JIS G3131/JIS G3106/

|

Materials |

Q195,Q215,Q235B,Q345B,

S235JR/S235/S355JR/S355

SS440/SM400A/SM400B |

Product Category | Metallurgy,Mineral &Energy |

Technique | HOT ROLLED |

Packing | 1.Big OD:in bulk 2.Small OD:packed by steel strips 3.woven cloth with 7 slats 4.according to the requirements of customers |

Usage | Mechanical&manufacture,Steel strcuture, Shipbuilding,Bridging,Automobile chassis |

Main market | Middle East,Africa, Asia and some Uropean country and America , Australia |

Country of origin

| China |

Productivity | 15000 Metric Tons pet Month |

Remark | Payment terms :T/T ,L/C Terms of trade :FOB ,CFR,CIF ,DDP,EXW Minimum order : 10 tons Lead time :on or before 3-15 working days . |

Company information

| We, ShunYun Industrial located in PuTuo district,ShangHai city China. Our products are sold to all over the country and exported to more than 50 countries such as the EU,theUnitedStates,Australia,Southest, Asia,the Middle East,etc. We shall a good -will of credit quality and prompt delivery and hold the belief of "quality for improvement ,credit for developments and customer first".So that can offer clients advanced products and satisfied service. We sincerely would like to set up business relationship with clients from all over the world in long term business. We view credibility as life. |

Logo | ShunYun shipping mark or your company logo |

Another Name | angle steel bar ,angle steel , steel angle , mild steel angle ,carbon steel bars |

Surface processing | you can Galvanized,coated,or as your request |

Technical | Shanghai Shunyun Industrial |

you Can | Customized Sizes |

Contact information

| TEL: +86-021-62153163 FAX: +86-021-62152536 |

- Q: What is the maximum load capacity of a steel angle?

- The maximum load capacity of a steel angle depends on various factors such as the dimensions, thickness, grade, and quality of the steel used. Generally, steel angles are designed to withstand significant loads due to their structural nature. However, it is important to consult engineering specifications and relevant building codes to determine the specific maximum load capacity of a steel angle in a given application. The load capacity is typically calculated by considering the angle's cross-sectional area, the material's yield strength, and the applied load factors. Additionally, factors such as the angle's length, support conditions, and the presence of any additional reinforcement or bracing can also influence the maximum load capacity. It is crucial to ensure that the steel angle is properly selected, designed, and installed to safely support the intended loads and meet the required structural standards.

- Q: What is the meaning of the number of angle steel

- The model does not mean the size of the different edges and sizes of the same model. Therefore, the width, the edge and the thickness of the angle iron should be filled out in the contract and other documents, so as not to be indicated by the model alone. The specification for hot rolled equilateral angle iron is No. 2 - 20.

- Q: Can steel angles be used for mezzanines or catwalks?

- Yes, steel angles can be used for mezzanines or catwalks. Steel angles are often used as structural supports in construction projects due to their strength and versatility. They can provide the necessary stability and load-bearing capacity required for mezzanines and catwalks, making them a suitable choice for such applications.

- Q: How do you calculate the moment resistance of a steel angle?

- The moment resistance of a steel angle can be calculated by determining the plastic section modulus of the angle and multiplying it by the yield strength of the steel.

- Q: Are steel angles suitable for historical restoration projects?

- Historical restoration projects can benefit from the suitability of steel angles. These versatile and durable materials are ideal for enhancing structural support and reinforcement in historic buildings. In fact, they can be employed to revive or duplicate original architectural elements like window frames, ornamental railings, and decorative features. Moreover, steel angles can be custom-made to perfectly match the original design, seamlessly merging with the existing structure. Nonetheless, it is crucial to take into account the specific demands and regulations of the historical restoration project, as some preservation authorities may impose limitations on the use of contemporary materials. Seeking guidance from experts in historical restoration and obtaining the necessary approvals will guarantee the appropriate and effective utilization of steel angles in preserving the historical integrity of the building.

- Q: Can steel angles be used in conveyor belt supports?

- Yes, steel angles can be used in conveyor belt supports. Steel angles are commonly used as structural supports in various applications due to their strength and durability. They provide excellent load-bearing capacity and can withstand heavy weights, making them suitable for supporting conveyor belts. The angles can be used to create a sturdy framework or structure that holds the conveyor belt in place and allows it to move smoothly. Additionally, steel angles can be easily fastened or welded together, providing a secure and stable support system for conveyor belts.

- Q: Can steel angles be drilled or cut?

- Yes, steel angles can be drilled or cut using appropriate tools and techniques.

- Q: How do you determine the required number of steel angles for a project?

- To determine the required number of steel angles for a project, you would typically need to consider the specific design and structural requirements of the project. This includes factors such as the dimensions and layout of the structure, the load-bearing capacity needed, and any specific codes or regulations that must be followed. A structural engineer or architect would typically perform calculations and analysis to determine the appropriate number of steel angles needed for the project.

- Q: What are the different methods of reinforcing steel angles?

- There are several methods of reinforcing steel angles, including using additional steel plates or bars to increase strength, welding additional steel angles or plates to provide additional support, or using structural adhesives to bond the steel angles together. Additionally, using bracing or connecting the angles to other structural components can also reinforce their strength.

Send your message to us

MS equal/unequal black & galvanized steel angle bar with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords