Equal_Unequal Black -Alvanized Steel Angle Bar with Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Detailed Information

Name | Equal/Unequal Angle Steel Bar |

Shape | Equal/Unequal Angle |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification

| 75*75 90 degree equal steel angle bar, angle iron steel |

Grade | Q195, Q215, Q235, Q345, SS400, A36, S235JR, ST37,etc |

Standard | AISI, ASTM, BS, DIN, GB, JIS, etc |

Equal Angle | 1)Type: 2#-20# |

2)Size: 20mm-200mm | |

3)Thickness: 3.0mm-18mm | |

Unequal Angle | 1)Type: 2.5/1.6-20/12.5 |

2)Long Side: 25-200mm | |

3)Short Side: 16-125mm | |

4)Thickness: 4.0-18mm | |

Length | 5.8m-12.0m or as your requirement |

Surface | Perforated/galvanized/black |

Inspection | BV,SGS,MTC,etc. |

Technique | Hot rolled |

Company Introduction

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

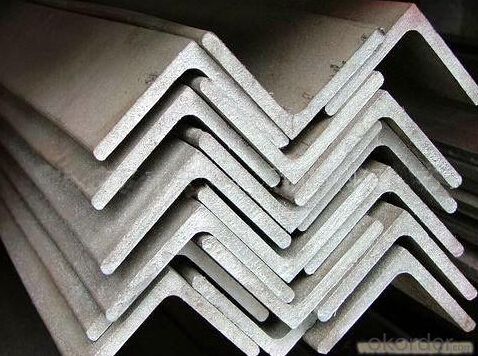

Products Show

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. |

Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. | |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel perform in cryogenic ductility?

- Special steel exhibits excellent performance in terms of cryogenic ductility. Cryogenic ductility refers to a material's ability to retain its strength and flexibility even at extremely low temperatures. Special steels are engineered specifically to endure harsh conditions, including cryogenic temperatures, making them suitable for applications such as LNG storage tanks, aerospace components, and superconductors. The composition of special steel is one of the key reasons for its exceptional cryogenic ductility. Generally, special steels are alloyed with elements like nickel, chromium, and molybdenum, which enhance their mechanical properties and resistance to low temperatures. These alloying elements provide the steel with increased strength, toughness, and resistance to brittle fracture, even in extremely cold environments. Moreover, special steels go through rigorous testing and quality control measures to ensure their performance in cryogenic conditions. This involves testing for parameters such as impact toughness, fracture toughness, and notch toughness, which are critical in assessing a material's ability to withstand brittle failure at low temperatures. Additionally, the manufacturing processes employed for special steel contribute to its excellent cryogenic ductility. Methods like vacuum induction melting and controlled cooling are often utilized to produce special steels. These techniques aid in eliminating impurities and improving the material's microstructure. This refined microstructure enhances the steel's ductility, enabling it to retain its mechanical properties even in cryogenic temperatures. In conclusion, special steel exhibits exceptional performance in terms of cryogenic ductility due to its meticulously designed composition, stringent testing, and advanced manufacturing processes. These factors make it a dependable and preferred choice for various industries that require materials capable of withstanding extreme cold conditions while maintaining strength and flexibility.

- Q: What are the different methods of surface finishing for special steel?

- There are several different methods of surface finishing for special steel, each offering unique benefits and achieving specific aesthetic or functional requirements. Some of the most commonly used methods include: 1. Electroplating: This process involves depositing a layer of metal onto the special steel surface through an electrochemical reaction. It provides enhanced corrosion resistance, improved appearance, and can also offer increased hardness or wear resistance. 2. Passivation: Passivation is a chemical treatment that removes surface contaminants and forms a thin oxide layer on the special steel. This process enhances corrosion resistance by preventing the formation of rust or other oxidation products. 3. Polishing: Polishing is a mechanical process that involves using abrasive materials to remove a thin layer of the steel surface, resulting in a smooth and shiny finish. This method is often used to improve the appearance of special steel products or to achieve a specific level of reflectivity. 4. Shot blasting: Shot blasting is a technique that involves propelling small metal beads or shots at high speed onto the special steel surface. This process removes scale, rust, or other surface contaminants, resulting in a clean and textured finish. Shot blasting is commonly used to prepare the steel for subsequent coating or painting applications. 5. Physical vapor deposition (PVD): PVD is a vacuum-based coating process that involves depositing a thin layer of material onto the special steel surface. This method offers excellent adhesion, wear resistance, and can provide various colors or finishes to enhance the aesthetics of the steel. 6. Powder coating: Powder coating involves applying a dry powder onto the special steel surface, which is then cured under heat to form a protective and decorative layer. This method offers excellent corrosion resistance, durability, and a wide range of color options. 7. Anodizing: Anodizing is an electrolytic process that creates a controlled oxide layer on the surface of certain special steel alloys. It provides increased corrosion resistance, improved appearance, and can also enhance hardness or wear resistance. These are just a few of the many methods available for surface finishing special steel. The choice of method will depend on factors such as the desired finish, functional requirements, and the specific properties of the steel being used.

- Q: Can special steel be used in the telecommunications industry?

- Yes, special steel can be used in the telecommunications industry. Special steel, such as stainless steel or high-strength steel, is often used for the construction of telecommunication towers, antennas, and other infrastructure due to its strength, durability, and corrosion resistance. It helps ensure the stability and reliability of telecommunications equipment, particularly in harsh weather conditions or areas prone to corrosion.

- Q: How does special steel contribute to the impact resistance of products?

- Special steel contributes to the impact resistance of products by providing superior strength, toughness, and durability. Its unique composition and manufacturing processes enhance its ability to withstand high impact forces without deforming or breaking. This makes it a valuable material for applications where products need to withstand heavy loads, vibrations, or collisions, ensuring their longevity and reliability.

- Q: What are the emerging trends in the special steel industry?

- Some emerging trends in the special steel industry include the increasing demand for high-strength and lightweight materials, the growing adoption of advanced manufacturing technologies such as 3D printing, the focus on sustainability and environmental impact reduction, and the rise of electric vehicles driving the need for specialized steel grades. Additionally, there is a shift towards customization and tailored solutions to meet specific industry requirements.

- Q: What is the role of special steel in sustainable manufacturing?

- Special steel plays a crucial role in sustainable manufacturing by offering numerous advantages that contribute to environmentally friendly production processes. Firstly, special steel is highly durable and has a long lifespan, which reduces the need for frequent replacement or repairs. This durability minimizes waste and extends the life cycle of products, reducing the overall environmental impact. Furthermore, special steel has excellent recyclability properties. It can be recycled multiple times without losing its quality or performance, making it a sustainable choice for manufacturers. By incorporating recycled special steel into the production process, manufacturers can reduce their reliance on virgin materials and decrease energy consumption and greenhouse gas emissions associated with the extraction and production of new steel. Moreover, special steel offers high strength and lightweight characteristics, enabling manufacturers to design products that are more energy-efficient. For example, in the automotive industry, using special steel in the manufacturing of vehicles reduces their weight, leading to improved fuel efficiency and lower emissions. This contributes to the reduction of carbon footprint and supports sustainable transportation. Special steel also plays a significant role in the production of renewable energy technologies. Wind turbines, solar panels, and hydropower systems require sturdy and resilient materials to withstand harsh conditions. Special steel provides the necessary strength, corrosion resistance, and durability required for these renewable energy infrastructure projects. By enabling the development of such technologies, special steel contributes to the growth of the renewable energy sector, which is essential for transitioning to a more sustainable energy mix. In conclusion, special steel plays a vital role in sustainable manufacturing by offering durability, recyclability, lightweight properties, and strength. By using special steel, manufacturers can reduce waste, energy consumption, and emissions, while also enabling the development of energy-efficient products and renewable energy technologies. Incorporating special steel into manufacturing processes is an essential step towards achieving a more sustainable and environmentally friendly future.

- Q: What are the common challenges in welding special steel?

- Welding special steel can present several challenges that differ from welding regular carbon steel. Some common challenges in welding special steel include: 1. High carbon content: Special steels often have a high carbon content, which can lead to increased hardness and brittleness. This can make it more difficult to achieve a proper weld without experiencing cracking or other defects. 2. High alloy content: Special steels often contain various alloying elements, such as chromium, nickel, or molybdenum, which can impact the weldability. These elements can introduce complexities, such as increased susceptibility to heat-affected zone (HAZ) cracking or the formation of brittle phases. 3. Heat sensitivity: Special steels are often more sensitive to heat input during welding. Excessive heat input can result in grain growth, reduced mechanical properties, or distortion of the welded structure. Therefore, careful control of heat input and preheating techniques may be necessary. 4. Pre-weld and post-weld treatments: Special steels may require specific pre-weld and post-weld treatments to ensure proper weld quality and performance. These treatments can include preheating, stress relieving, or post-weld heat treatment. Failure to follow these procedures can lead to the development of residual stresses or reduced mechanical properties. 5. Joint design and fit-up: The design and fit-up of the weld joint can also pose challenges. Special steels may require specific joint configurations, such as a double-V or double-U groove, to ensure proper penetration and fusion. Additionally, tight tolerances may be necessary to maintain the desired mechanical properties of the welded structure. 6. Welding process selection: The choice of welding process can greatly impact the success of welding special steel. Some processes, such as TIG or laser welding, may be more suitable for welding high-alloy steels, while others like MIG or submerged arc welding may be better suited for specific applications. Selecting the appropriate welding process is crucial to achieving a sound weld with the desired properties. To overcome these challenges, it is essential to have a thorough understanding of the specific type of special steel being welded and to follow proper welding procedures and techniques. This may involve conducting pre-weld qualification tests, employing suitable welding consumables, and ensuring proper heat control throughout the welding process. Additionally, working with experienced welders and seeking guidance from experts in special steel welding can help overcome these challenges effectively.

- Q: How is special steel used in the textile industry?

- Special steel is commonly used in the textile industry for the production of various machinery and equipment such as needles, pins, and wire guides. These steel components are essential in processes like knitting, weaving, and sewing, as they provide durability, strength, and precision, ensuring smooth operation and quality output in textile manufacturing.

- Q: What is the significance of phosphorus in special steel?

- Phosphorus plays a significant role in the production of special steel due to its various beneficial properties. Firstly, phosphorus acts as a deoxidizer, helping to remove impurities such as oxygen from the steel during the manufacturing process. This improves the overall quality and purity of the steel, making it more resistant to corrosion and enhancing its mechanical properties. Moreover, phosphorus can increase the strength and hardness of the steel, making it suitable for applications that require high durability and wear resistance. It also helps in improving the machinability of the steel, allowing for easier shaping and processing. Additionally, phosphorus enhances the steel's ability to retain its strength at elevated temperatures, making it suitable for applications in high-temperature environments, such as power plants or aerospace industries. However, while phosphorus offers these advantages, it is important to control its concentration within certain limits, as excessive levels can lead to detrimental effects. High phosphorus content can result in brittleness, reduced toughness, and decreased weldability of the steel. Therefore, careful consideration is necessary to balance the beneficial effects of phosphorus with its potential drawbacks. In summary, the significance of phosphorus in special steel lies in its ability to improve the quality, purity, strength, hardness, machinability, and high-temperature performance of the steel. By controlling the phosphorus content within appropriate limits, manufacturers can produce special steel with enhanced properties, meeting the specific requirements of various industrial applications.

- Q: What are the applications of special steel in the oil and gas supply chain?

- Special steel has various applications in the oil and gas supply chain. It is commonly used in the construction of pipelines, offshore platforms, and drilling equipment due to its high strength, corrosion resistance, and ability to withstand extreme conditions. Special steel also finds its utility in the manufacturing of valves, fittings, and connectors, ensuring efficient and leak-free operations. Additionally, it is used in the production of storage tanks and vessels, providing reliability and safety in the containment of oil and gas. Overall, special steel plays a crucial role in enhancing the durability, performance, and safety of equipment and infrastructure within the oil and gas supply chain.

Send your message to us

Equal_Unequal Black -Alvanized Steel Angle Bar with Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords