Equal-Unequal Grade CNBM Black & Galvanized Steel Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Equal-Unequal Grade CNBM Black & Galvanized Steel Angle Bar

Detailed Informaion

Name | Equal/Unequal Angle Steel Bar |

Shape | Equal/Unequal Angle |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification

size A*B | size allow-able deviation | thickness | |||||||||

3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||

thickness allowable deviation | |||||||||||

25*25 | ±1.5 | ±0.5 | ±0.5 | ±0.5 |

|

|

|

|

|

|

|

30*30 | ±2.0 | ±0.5 | ±0.5 | ±0.5 | ±0.5 |

|

|

|

|

|

|

40*40 | ±2.0 | ±0.6 | ±0.6 | ±0.6 | ±0.6 |

|

|

|

|

|

|

50*50 | ±2.0 | ±0.6 | ±0.6 | ±0.6 | ±0.6 |

|

|

|

|

|

|

60*60 | ±3.0 |

| ±0.6 | ±0.6 | ±0.6 | ±0.6 |

|

|

|

|

|

65*65 | ±3.0 |

|

| ±0.6 | ±0.6 | ±0.7 | ±0.7 | ±0.7 |

|

|

|

70*70 | ±3.0 |

|

| ±0.7 | ±0.7 | ±0.7 | ±0.7 | ±0.7 | ±0.7 |

|

|

75*75 | ±3.0 |

|

|

| ±0.7 | ±0.7 | ±0.7 | ±0.7 | ±0.7 |

|

|

80*80 | ±3.0 |

|

|

| ±0.7 | ±0.7 | ±0.7 | ±0.7 | ±0.7 |

|

|

100*100 | ±4.0 |

|

|

|

| ±0.7 | ±0.7 | ±0.7 | ±0.8 | ±0.8 | ±0.8 |

Company Introduction

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

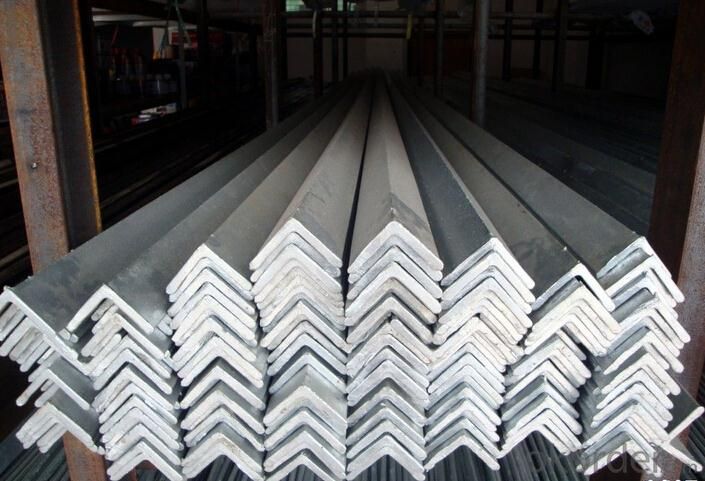

Product Show

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. |

Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. | |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel contribute to improving product safety in high-risk industries?

- Special steel contributes to improving product safety in high-risk industries by providing enhanced strength, durability, and resistance to various hazardous conditions. Its unique properties, such as high tensile strength, corrosion resistance, and heat resistance, make it an ideal material for manufacturing critical components and structures in industries like aerospace, automotive, oil and gas, and construction. By using special steel, manufacturers can ensure that their products can withstand extreme conditions, reducing the risk of failures, accidents, and potential harm to workers or the environment.

- Q: How is special steel tested for quality?

- Special steel is tested for quality through various processes such as chemical analysis, mechanical testing, and non-destructive testing. Chemical analysis involves checking the composition and purity of the steel to ensure it meets the required specifications. Mechanical testing includes assessing the strength, hardness, and toughness of the steel through methods like tensile testing, impact testing, and hardness testing. Non-destructive testing techniques like ultrasonic testing, magnetic particle inspection, and radiographic testing are employed to detect any defects or irregularities within the steel without causing any damage. These comprehensive tests ensure that special steel meets the necessary quality standards before it is used in various industries.

- Q: What are the different testing methods used for special steel?

- Some of the different testing methods used for special steel include hardness testing, tensile testing, impact testing, metallographic examination, ultrasonic testing, and magnetic particle testing.

- Q: What are the different types of welding techniques used for special steel?

- There are several types of welding techniques used for special steel, including TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, Stick welding, and Flux-cored arc welding. These techniques are commonly used for welding special steel due to their ability to provide strong and precise welds, ensuring the integrity and durability of the material.

- Q: What are the advantages of using special steel in industrial applications?

- Using special steel in industrial applications has several advantages. Firstly, it offers exceptional strength and durability, making it suitable for heavy-duty tasks. The unique composition and manufacturing process of special steel result in a material that can withstand high levels of stress, extreme temperatures, and harsh environmental conditions. This makes it ideal for industries such as construction, automotive, and manufacturing, where reliable and long-lasting materials are required. Secondly, special steel exhibits excellent corrosion resistance. It can resist the damaging effects of moisture, chemicals, and other corrosive agents, which is crucial in industries like marine, oil and gas, and chemical processing. The corrosion resistance of special steel reduces the need for frequent maintenance and replacement, saving both time and costs for industrial applications. Furthermore, special steel offers superior machinability and formability. It can be easily shaped, cut, and welded to meet specific design requirements. This versatility allows for complex and intricate designs in various industrial applications, including machinery, tools, and equipment. Another advantage of special steel is its ability to maintain its properties at high temperatures. It has excellent heat resistance, ensuring that it remains strong and stable even under extreme heat conditions. This makes special steel suitable for applications involving high-temperature environments, such as aerospace, power generation, and furnace components. Additionally, special steel can exhibit excellent wear resistance and hardness. It can withstand abrasion, friction, and impact, making it ideal for applications where materials are subjected to heavy wear and tear, such as mining, construction equipment, and cutting tools. The wear resistance of special steel ensures that components have a longer lifespan and require less frequent replacement. In conclusion, the use of special steel in industrial applications brings forth exceptional strength and durability, corrosion resistance, machinability and formability, heat resistance, and wear resistance. These properties make special steel a preferred choice for a wide range of industries, contributing to improved performance, longevity, and cost-effectiveness.

- Q: How does special steel contribute to the energy equipment industry?

- Special steel plays a crucial role in the energy equipment industry by providing materials with superior strength, durability, and corrosion resistance. These properties enable the production of high-performance components such as turbine blades, pressure vessels, and pipelines, which are essential for power generation, transmission, and distribution. Additionally, special steel's ability to withstand extreme temperatures and harsh operating conditions enhances the efficiency and reliability of energy equipment, ultimately contributing to the overall sustainability and advancement of the industry.

- Q: What are the specific requirements for special steel used in the defense sector?

- Due to the critical nature of its applications, the defense sector imposes highly demanding requirements on special steel. These requirements encompass: 1. Exceptional strength and durability: Special steel utilized in the defense sector must possess outstanding strength and durability to withstand extreme conditions and endure wear and tear. It should have the capacity to endure high levels of stress, impact, and pressure. 2. Superior corrosion resistance: Defense equipment frequently operates in harsh environments and is exposed to elements that can cause corrosion. Consequently, special steel employed in the defense sector must display excellent corrosion resistance properties to ensure the equipment's longevity and reliability. 3. Heat resistance: Defense applications often involve exposure to high temperatures, such as in jet engines or armored vehicle components. Special steel used in these sectors must retain its strength and structural integrity even at elevated temperatures. 4. Machinability and weldability: Special steel employed in the defense sector should possess favorable machinability and weldability characteristics to facilitate manufacturing and assembly processes. This allows for ease of fabrication, repair, and maintenance of defense equipment. 5. Hardness and toughness: Defense applications necessitate a combination of hardness and toughness in special steel. It must resist penetration and deformation while simultaneously being able to absorb energy and resist fracture. 6. Non-magnetic properties: In specific defense applications, such as submarines and magnetic resonance imaging (MRI) equipment, non-magnetic properties are essential. Special steel employed in these sectors must possess low magnetic permeability to prevent interference with sensitive electronic systems. 7. Certification and compliance: Special steel used in the defense sector must meet specific certification and compliance standards, such as those established by defense organizations or international quality management systems like ISO 9001. These standards guarantee the quality, traceability, and reliability of the steel. Meeting these specific requirements for special steel utilized in the defense sector is crucial to ensure the safety, effectiveness, and longevity of defense equipment and systems. Rigorous testing and quality control processes are implemented to ensure that the steel meets the required specifications and standards.

- Q: How does special steel perform in high-temperature mechanical fatigue conditions?

- Special steel, known for its high strength and resistance to heat, performs exceptionally well in high-temperature mechanical fatigue conditions. Its unique composition and properties enable it to withstand prolonged exposure to elevated temperatures without significant loss of mechanical integrity or performance. This makes special steel a reliable and durable material choice for applications that involve repetitive cyclic loading and heat exposure, such as in aerospace, power generation, and automotive industries.

- Q: What are the properties of ultra-high-strength steel?

- Ultra-high-strength steel possesses exceptional mechanical properties, including high tensile strength, excellent toughness, and superior fatigue resistance. It exhibits high stiffness, enabling it to withstand heavy loads and maintain its shape even under extreme conditions. With its low weight and high strength-to-weight ratio, this steel offers enhanced fuel efficiency and increased payload capacity. Additionally, it exhibits good weldability, corrosion resistance, and is often used in applications where both strength and durability are paramount, such as in automotive, aerospace, and construction industries.

- Q: What are the potential health hazards associated with working with special steel?

- Working with special steel can pose potential health hazards due to the materials and processes involved. Some of the main health hazards associated with working with special steel include: 1. Inhalation of hazardous fumes: Special steels often contain various alloys and elements, such as chromium, nickel, and manganese, which can release toxic fumes when heated or welded. Prolonged exposure to these fumes can lead to respiratory issues, such as bronchitis, asthma, or even lung cancer. 2. Skin and eye irritation: Steelworking involves handling sharp edges, cutting tools, and abrasive materials, which can cause cuts, scratches, or puncture wounds. These injuries can become infected or lead to more serious conditions if not properly treated. Additionally, contact with certain alloys in special steel can irritate the skin or cause allergic reactions. Eye protection is crucial in this industry to prevent eye injuries from flying debris or sparks. 3. Noise-induced hearing loss: Steel manufacturing processes often involve heavy machinery, which generates high levels of noise. Prolonged exposure to such noise levels can lead to permanent hearing loss or other auditory issues. Workers should use appropriate hearing protection, such as earmuffs or earplugs, to minimize the risk. 4. Ergonomic hazards: Steelworking often requires repetitive movements, heavy lifting, or awkward postures, which can lead to musculoskeletal disorders, such as back pain, carpal tunnel syndrome, or tendonitis. Employers should implement proper ergonomic practices, including providing adjustable workstations, lifting aids, and regular breaks to prevent these hazards. 5. Thermal hazards: Special steel manufacturing processes involve high temperatures, such as welding or forging, which can lead to burns if proper protective clothing or equipment is not used. Exposure to extreme heat can also cause heat-related illnesses, including heat exhaustion or heat stroke. Adequate training, appropriate personal protective equipment (PPE), and regular breaks in cooler areas can help mitigate these risks. To protect workers from these potential health hazards, employers should implement proper safety protocols, including employee training, use of personal protective equipment, regular health monitoring, and maintaining a clean and well-ventilated work environment. Occupational health and safety regulations should be strictly followed to minimize the risks associated with working with special steel.

Send your message to us

Equal-Unequal Grade CNBM Black & Galvanized Steel Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords