Monolithic Refractories for Iron and Steel Industry - Covering Fluxes and Powders

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

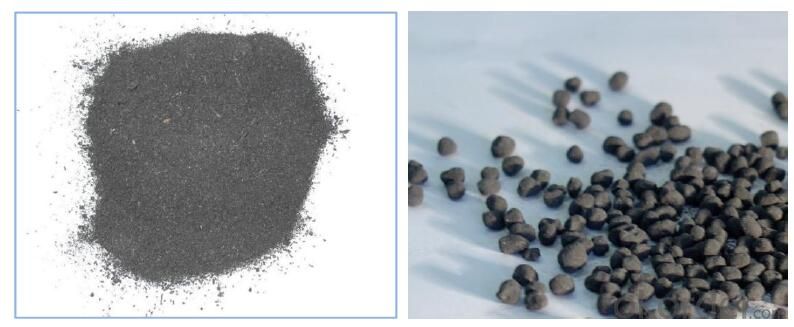

We offer a series of covering flux products including both fine-grained powders and hollow granulated fluxes, so it’s possible for customer to select a suitable material according to operational parameters of each specific application.

Generally for tundish application factors affecting product performance result to be steel grade, exposed steel surface to be covered, casting time, and sequence index.

Regarding ladle applications, critical factors are chiefly the amount and the characteristics of the refining slag.

Increasing demand of better quality steel and subsequent use of high performance basic tundish lining material boosted researching and developing of active basic tundish powders assuring high covering, insulating properties and low corrosion activity.

Moreover, effective NMI (non-metallic inclusions) absorption capability is provided by specific viscosity and surface tension of molten slag layer in direct contact with molten steel.

Plant experience in using these active basic tundish powders gave improved steel cleanness.

Insulating covering fluxes for tundish and ladle

We offer two types of insulating covering fluxes :

Rice ash, with high levels of thermal insulation

Fly ash mixtures, with high levels of thermal insulation and protection against re-oxidation

Insulating MgO-based covering fluxes

Spray-dried covering powders based on magnesite and with very low silica content, with good thermal insulation properties, protection against re-oxidation and low refractory erosion.

Active basic powders

We offer two types of active basic powders:

Active basic powders for tundish (CaO-based) in fine-grain powders and granulated form to maximize absorption of NMI.

Calcium aluminate based material is well known to give metallurgical active slags able to prevent sulphur pick up to the steel. It offers the potential for oxide pick-up and protection against re-oxidation. It is a material obtained by complete melting in high-capacity furnaces of bauxite and limestone. Because such materials have poor insulating properties, it is necessary to add an additional insulating compound on top.

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: In iron and steel industry, the main raw materials for blast furnace ironmaking are iron ore, coke and limestone. What's the use of limestone here?

- CaCO3 CaO + CO2 =C = 2CO + CO2Fe2O3

- Q: How do monolithic refractories improve the efficiency of ladle and tundish purging furnaces?

- Monolithic refractories play a crucial role in improving the efficiency of ladle and tundish purging furnaces in several ways. Firstly, monolithic refractories have excellent thermal insulation properties. This means that they can retain heat within the furnace, minimizing heat loss to the surroundings. By reducing heat loss, monolithic refractories enable the furnaces to operate at higher temperatures, which in turn leads to improved efficiency. The higher temperatures allow for better steel refining, faster heating and purging of the ladle and tundish, and overall increased productivity. Secondly, monolithic refractories offer superior resistance to thermal shock. Purging furnaces, especially ladles and tundishes, undergo rapid heating and cooling cycles due to the continuous flow of molten metal. This thermal cycling can cause traditional refractories to crack or fail, leading to reduced efficiency and increased downtime for repairs. However, monolithic refractories have the ability to withstand these extreme temperature changes, ensuring continuous operation and minimizing the need for frequent maintenance. Thirdly, monolithic refractories provide excellent resistance to chemical attacks from molten metals and slag. During the purging process, ladles and tundishes come into contact with aggressive materials that can erode the refractory lining. Monolithic refractories are specifically engineered to withstand these harsh environments, preventing erosion and prolonging the lifespan of the furnaces. This resistance to chemical attacks not only improves efficiency by minimizing refractory wear, but also ensures the production of high-quality steel with reduced impurities. Lastly, monolithic refractories offer great versatility in terms of installation and repair. Unlike traditional refractories that require complex bricklaying techniques, monolithic refractories can be easily shaped and installed, allowing for faster and more efficient lining construction. Additionally, monolithic refractories can be easily repaired or patched, reducing downtime and ensuring continuous operation of the furnace. In conclusion, monolithic refractories greatly improve the efficiency of ladle and tundish purging furnaces by providing excellent thermal insulation, resistance to thermal shock and chemical attacks, as well as ease of installation and repair. These properties allow for higher operating temperatures, reduced heat loss, increased productivity, and prolonged furnace lifespan, ultimately enhancing the overall efficiency and performance of the steelmaking process.

- Q: How are monolithic refractories installed and repaired in iron and steel applications?

- Monolithic refractories are installed and repaired in iron and steel applications using specific procedures to ensure optimal performance and longevity. The installation process typically involves the following steps: 1. Surface preparation: The surface where the monolithic refractory will be installed needs to be properly cleaned and prepared. This includes removing any loose material, dirt, and dust. It is crucial to have a smooth and clean substrate to ensure good adherence of the refractory material. 2. Mixing the refractory material: Monolithic refractories are typically supplied as dry powders or granules that need to be mixed with water or a specific bonding agent to form a workable consistency. The mixing process should be done according to the manufacturer's instructions to achieve the desired properties of the refractory. 3. Application: The mixed refractory material is then applied to the prepared surface using various techniques such as troweling, spraying, or casting. The choice of application method depends on the specific requirements of the installation and the type of monolithic refractory being used. 4. Curing: After the refractory material is applied, it needs to be properly cured to achieve its maximum strength and durability. Curing can be done by air drying, using heat, or a combination of both, depending on the specific refractory material being used. The curing process should be carried out gradually and according to the manufacturer's recommendations. When it comes to repairs of monolithic refractories in iron and steel applications, the following steps are generally followed: 1. Assessment: The damaged area or component needs to be thoroughly assessed to determine the extent of the damage and the appropriate repair method. 2. Removal of damaged material: The damaged monolithic refractory material is carefully removed using appropriate tools and techniques. It is important to remove all the damaged material while ensuring that the underlying substrate is not further compromised. 3. Surface preparation: Similar to the installation process, the surface where the repair will be carried out needs to be properly cleaned and prepared. Any loose material, dirt, and dust should be removed to create a clean and smooth substrate. 4. Application of repair material: The repair material, which is typically the same or similar to the original monolithic refractory, is mixed and applied to the damaged area. The application method may vary depending on the nature of the repair and the specific requirements of the refractory material. 5. Curing and post-repair inspection: The repaired area should be properly cured and inspected to ensure the quality and effectiveness of the repair. Curing and inspection procedures should adhere to the manufacturer's guidelines. In summary, the installation and repair of monolithic refractories in iron and steel applications require careful surface preparation, proper mixing and application of the refractory material, and appropriate curing procedures. Following these steps in a meticulous manner ensures reliable and durable refractory linings, which are essential for the efficient operation of iron and steel processes.

- Q: How do monolithic refractories improve the performance and efficiency of iron and steel production?

- Monolithic refractories play a crucial role in improving the performance and efficiency of iron and steel production. These specialized materials are designed to withstand extreme temperatures, chemical reactions, and mechanical stresses, making them ideal for use in high-temperature industrial processes. One of the key ways in which monolithic refractories enhance performance is by providing a protective lining in furnaces, kilns, and other equipment used in iron and steel production. Due to their superior heat resistance, they protect the underlying structure from the intense heat and prevent any detrimental effects on the equipment. This results in reduced downtime, longer service life, and ultimately, increased overall efficiency. Monolithic refractories also ensure better thermal efficiency in the production process. By minimizing heat losses, these materials help to maintain a stable and uniform temperature distribution, thereby improving the energy efficiency of the system. This is particularly important in iron and steel production, where precise temperature control is crucial for achieving the desired metallurgical properties of the final product. Furthermore, monolithic refractories offer excellent resistance to chemical corrosion, erosion, and slag attacks. They act as a barrier between the molten metal and the refractory lining, preventing undesirable reactions and material degradation. This helps to maintain the integrity of the furnace lining, reducing the need for frequent repairs or replacements. Consequently, it leads to increased productivity and cost savings in the long run. Another advantage of monolithic refractories is their ability to be easily shaped, repaired, or replaced. Unlike traditional brick refractories, which require extensive labor and time-consuming installation, monolithic refractories can be applied in a more flexible and efficient manner. Their flexible nature allows for easy repair of damaged areas, minimizing downtime and ensuring continuous production. In summary, the use of monolithic refractories significantly enhances the performance and efficiency of iron and steel production. These materials provide a protective lining, improve thermal efficiency, resist chemical corrosion, and offer easy installation and repair options. By optimizing the production process, monolithic refractories contribute to higher productivity, reduced downtime, and increased cost-effectiveness in the iron and steel industry.

- Q: How do monolithic refractories mitigate heat loss in iron and steel operations?

- Monolithic refractories are highly effective in mitigating heat loss in iron and steel operations due to their unique properties and composition. These refractories are made from a single, continuous material, making them resistant to cracks and gaps that could allow heat to escape. One key advantage of monolithic refractories is their excellent thermal conductivity and insulation properties. They have a low thermal conductivity, which means they can effectively restrict the transfer of heat from the hot areas to the cooler surroundings. This insulation property helps maintain high temperatures within the iron and steel operations, reducing heat loss to the environment. Another factor that contributes to the heat loss mitigation is the ability of monolithic refractories to form a tight seal with the metal structures they are applied to. They adhere well to the surfaces and fill in any gaps or irregularities, creating a solid barrier against heat loss. This seal minimizes the possibility of heat escaping, ensuring that the energy generated within the operations is effectively utilized. Furthermore, monolithic refractories have high resistance to thermal shock. In the iron and steel industry, extreme temperature fluctuations are common, which can lead to material deterioration and cracks. Monolithic refractories, with their high thermal shock resistance, are able to withstand these rapid temperature changes without compromising their structural integrity. This ensures the longevity and effectiveness of the refractories in mitigating heat loss. Overall, monolithic refractories play a crucial role in mitigating heat loss in iron and steel operations by providing excellent insulation, forming a tight seal, and withstanding thermal shock. These properties allow the refractories to maintain high temperatures within the operations, optimize energy utilization, and enhance the overall efficiency of the processes.

- Q: Can monolithic refractories be used for the lining of ladle refining furnaces and VOD converters?

- Yes, monolithic refractories can be used for the lining of ladle refining furnaces and VOD converters. Monolithic refractories are versatile and can be shaped and installed easily, making them suitable for lining various types of furnaces and converters, including ladle refining furnaces and VOD converters.

- Q: What are the specific requirements of monolithic refractories for ladle transfer applications?

- To ensure the effectiveness and durability of monolithic refractories used in ladle transfer applications, specific requirements must be met. These requirements are crucial for maintaining the integrity of the ladle lining and preventing any issues during the transfer process. Firstly, it is essential for monolithic refractories designed for ladle transfer applications to possess excellent thermal shock resistance. Ladles undergo extreme temperature changes during the transfer process, and the refractories must be capable of withstanding rapid heating and cooling without developing cracks or spalling. This property serves to prevent any damage to the lining and preserves the structural integrity of the ladle. Secondly, ladle transfer applications necessitate monolithic refractories that exhibit high resistance to chemical attack. Ladles often come into contact with various molten metals and slag, which can possess corrosive properties. The refractories must be able to endure these corrosive environments and maintain their physical and chemical properties over time. Another crucial requirement is good mechanical strength. Ladles can experience significant mechanical stress during the transfer process, including impacts and vibrations. Therefore, the monolithic refractories must possess sufficient strength to resist these mechanical forces and prevent any cracking or failure within the lining. Furthermore, ladle transfer applications frequently involve the use of fluxes and additives, which can possess different physical properties. The refractories used must be compatible with these fluxes and additives to ensure proper performance and avoid any adverse reactions that could impact the lining of the ladle. Lastly, monolithic refractories designed for ladle transfer applications should exhibit low porosity. Low porosity helps to minimize the penetration of molten metal and slag into the refractory lining, thereby reducing the risk of erosion and extending the service life of the refractories. In summary, the specific requirements for monolithic refractories in ladle transfer applications include excellent thermal shock resistance, high resistance to chemical attack, good mechanical strength, compatibility with fluxes and additives, and low porosity. By meeting these requirements, the refractories can effectively endure the harsh conditions of ladle transfer and ensure the longevity and performance of the ladle lining.

- Q: What are the typical properties of monolithic refractories used in iron and steel industry?

- Monolithic refractories used in the iron and steel industry generally possess several key properties that make them suitable for the harsh operating conditions in these industries. Firstly, monolithic refractories have excellent thermal shock resistance. They can withstand rapid temperature changes without cracking or spalling, which is crucial in the iron and steel industry where the heating and cooling processes can be highly intense. Secondly, these refractories exhibit high refractoriness, meaning they can withstand extremely high temperatures without losing their strength or shape. This is essential in environments where temperatures can reach well above 1000 degrees Celsius. Additionally, monolithic refractories used in the iron and steel industry are known for their excellent corrosion resistance. They can resist the corrosive effects of molten metals, slags, and gases that are commonly encountered in these industrial processes. Furthermore, these refractories have good mechanical strength and abrasion resistance, allowing them to withstand the physical stresses and wear caused by handling and mechanical operations. Another important property of monolithic refractories is their ability to form strong bonds with the existing refractory lining. This ensures a secure and long-lasting installation, reducing the risk of failure and minimizing downtime for maintenance or repairs. Lastly, these refractories often have low porosity, which prevents the infiltration of molten metal or slag into the lining. This helps to maintain the integrity of the refractory structure and prolong its service life. Overall, the typical properties of monolithic refractories used in the iron and steel industry include thermal shock resistance, high refractoriness, corrosion resistance, mechanical strength, strong bonding, and low porosity. These properties collectively contribute to the efficient and reliable operation of iron and steel manufacturing processes.

- Q: What are the factors affecting the lifespan of monolithic refractories?

- The lifespan of monolithic refractories can be significantly affected by several factors. 1. Operating temperature is a critical factor. While monolithic refractories are designed to withstand high temperatures, prolonged exposure to extreme temperatures can cause thermal shock and lead to premature failure. 2. Thermal cycling, which refers to frequent temperature fluctuations, can also shorten the lifespan of monolithic refractories. The refractory material expands and contracts, creating stress that can result in cracking and degradation over time. 3. The chemical environment where the monolithic refractories are used plays a crucial role in their lifespan. Exposure to corrosive gases, acids, alkalis, or molten metals can cause chemical reactions that degrade the refractory material. 4. Mechanical stress, such as abrasion, impact, and vibration, can weaken monolithic refractories and reduce their lifespan. This is particularly important in industries with high mechanical activity, such as steelmaking or cement production. 5. Proper installation and regular maintenance are essential for maximizing the lifespan of monolithic refractories. Inadequate installation techniques or neglecting maintenance can result in weak joints, inadequate anchoring, or the growth of cracks, leading to premature failure. 6. The quality and composition of the monolithic refractory material greatly impact its lifespan. Higher-quality materials with better resistance to temperature, chemical attacks, and mechanical stress tend to have longer lifespans. 7. The design of the refractory lining and its engineering considerations, such as thickness, shape, and reinforcement, also influence the lifespan of monolithic refractories. A proper design can distribute stress more evenly, reduce thermal gradients, and improve overall performance and durability. 8. The way monolithic refractories are operated and handled can affect their lifespan. Factors such as rapid temperature changes, improper cooling or heating procedures, or excessive thermal cycling can all contribute to premature failure. In conclusion, various factors such as temperature, thermal cycling, chemical environment, mechanical stress, installation and maintenance practices, quality of refractory material, design and engineering considerations, and operating conditions all impact the lifespan of monolithic refractories. Proper management and consideration of these factors are essential for maximizing their lifespan.

- Q: How do monolithic refractories contribute to reducing downtime in iron and steel plants?

- Monolithic refractories contribute to reducing downtime in iron and steel plants by providing enhanced durability and resistance to high temperatures, chemical corrosion, and mechanical wear. These refractories can be quickly and easily installed, repaired, or replaced, minimizing the time required for maintenance and reducing production interruptions. Their versatile and customizable nature allows for efficient lining of various equipment, such as furnaces, ladles, and converters, ensuring a continuous and uninterrupted production process.

Send your message to us

Monolithic Refractories for Iron and Steel Industry - Covering Fluxes and Powders

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords