Monolithic Refractories Ceramic Lined Ceramic Ball Valve for Iron and Steel Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

Applied in any media, expect HF (Hydrofluoric Acid) or glass solution, with max. temperature up to 500°C or max pressure 5.0 Mpa, such as high corrosion, high attrition and middle pressure.

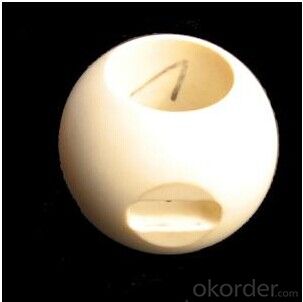

Structural: 3-part flange type float ball valve Flange standards follow DIN/ANSI/API/JIS

l Excellent wear-proof property of ceramic enables this valve have high reliability and prolonged lifespan which is 2-4times as much as Titannium Alloy and Monel Metal valve.

l Elastic O ring fit between metal part and ceramic part makes the whole part high sealing capacity, unables the two parts blind, and avoid the ball broken.

l Valve steams are selected among 316/316L stainless steel, HC alloy, Monel Alloy, structural ceramic.

l Completely symmetric design ensures dual leak-proof and two-direction usage to prolong its lifespan to twice.

All parts that connect the medium are made of structural ceramics with extremely high chemical stability and hardness (HRC 90), which is only inferior to diamond. So the valve features exceedingly high wear-proof capability, corrosion resisting, enduring capability, good heat insulation, small thermal expansion.

The valve is unique in granule medium of high hardness, or erosive soft granule and is the only choice for such medium. They are wisely used in FDG System, Slag system and LNCFS in power plant, saline water and distilling processes in alkali works, paper pulp system in paper mill, and so on.

The ball is processed by advanced polishing equipment and technology that can ensure high circularity, good surface quality,.

The self-lubricating capability of ZrO2, ensure the good sealing performance between the ball and its seat. It is thoroughly free from the defects of easy leakage, big torque, non-resistance sealing surface comparing with metal sealing valve.

ZrO2 Composition Chart of MZ Ceramic Ball Valve

NO. | Physical Property | Parameter |

1 | Crystal | >85% cubic, the rest monoclinic |

2 | Lg. Loss | 0.8%-1.0% |

3 | Average | 0.4-0.7um |

4 | Apparent Density | >0.4g/cc |

5 | ZrO2 Purity | >99.95% |

6 | Tapped Density | >0.8g/cc |

- Q: How do monolithic refractories improve the lining of converters and refining vessels?

- Improving the lining of converters and refining vessels is a crucial role played by monolithic refractories in several ways. To begin with, these refractories offer exceptional thermal insulation properties, which effectively maintain the desired temperature within the converters and refining vessels. This is particularly important as the metallurgical processes require high temperatures to be effective. Furthermore, the high chemical resistance of monolithic refractories is vital in the harsh conditions of converters and refining vessels. These vessels often come into contact with corrosive materials and aggressive slags, but the monolithic refractories prevent any deterioration or erosion of the lining caused by these substances. In addition, the mechanical strength and stability provided by monolithic refractories ensure that the lining remains intact even under high operational stresses. This is especially significant in converters and refining vessels where frequent mechanical movements and thermal expansions occur. Moreover, monolithic refractories offer easy installation and repair compared to traditional bricks, which require complex and time-consuming assembling. Monolithic refractories can be applied as a single mass, minimizing downtime during installation or repair. This results in time and cost savings for maintaining the lining of converters and refining vessels. Overall, the utilization of monolithic refractories significantly enhances the performance and longevity of converters and refining vessels. Their excellent thermal insulation, chemical resistance, mechanical strength, and ease of installation and repair guarantee efficient and reliable operation in metallurgical processes.

- Q: How do monolithic refractories enhance the performance of ladles and tundishes?

- Monolithic refractories enhance the performance of ladles and tundishes by providing superior thermal insulation, high resistance to thermal shock, and excellent chemical resistance. This improves their durability, reduces heat loss, and minimizes the risk of refractory failure, resulting in increased operational efficiency and extended service life of ladles and tundishes.

- Q: How do monolithic refractories perform in rotary kiln applications?

- Due to their unique properties and characteristics, monolithic refractories prove highly effective in rotary kiln applications. Unlike traditional brick and mortar refractories, these refractories are designed to be installed as a single, solid unit. One of the primary advantages of monolithic refractories in rotary kilns is their incredible ability to withstand high temperatures and thermal stresses. Operating at temperatures as high as 3000 degrees Fahrenheit, rotary kilns subject refractories to extreme conditions. However, monolithic refractories excel in handling such temperatures without cracking or failing, ensuring the longevity and reliability of the kiln. Another crucial performance aspect of monolithic refractories in rotary kilns is their resistance to chemical attack. Industries like cement production often employ rotary kilns, where the materials being processed can be highly corrosive. Monolithic refractories offer excellent protection against chemical attack, safeguarding the kiln from deterioration and extending its service life. Moreover, monolithic refractories are renowned for their exceptional thermal conductivity and insulation properties. This aids in maintaining consistent and efficient heat transfer within the kiln, thereby enhancing the overall energy efficiency of the process. Furthermore, the installation of monolithic refractories in rotary kilns is relatively quick and straightforward compared to traditional brick and mortar refractories. The monolithic materials can be cast or gunned into place, creating a seamless lining that eliminates the need for individual bricks and mortar joints. This not only saves time during installation but also minimizes the potential for weak points or gaps in the lining, guaranteeing a more durable and effective refractory system. In conclusion, monolithic refractories offer outstanding performance in rotary kiln applications. Their ability to withstand high temperatures, resist chemical attack, provide efficient heat transfer, and offer easy installation make them the preferred choice for industries relying on rotary kilns in their production processes.

- Q: How do monolithic refractories contribute to the reduction of heat loss in iron and steel plants?

- The unique properties and application methods of monolithic refractories are crucial in the efforts to minimize heat loss in iron and steel plants. These refractories consist of single, continuous materials without joints or seams, providing exceptional thermal insulation and reducing heat transfer. A key factor in the reduction of heat loss is the low thermal conductivity of monolithic refractories. These materials possess a high resistance to heat flow, effectively preventing the loss of thermal energy from furnaces, ladles, and other equipment used in iron and steel production. By creating a barrier between the hot interior and cooler surroundings, monolithic refractories effectively minimize heat escape and maintain a stable and efficient thermal environment. Furthermore, monolithic refractories are known for their excellent adhesion and strength, allowing them to form a tight seal and eliminate gaps or cracks in equipment linings. This prevents the entry of cold air and the escape of hot gases, further reducing heat loss and ensuring optimal operating temperatures are maintained. Another advantage of monolithic refractories is their ease of application and repair, leading to a more efficient and cost-effective maintenance process. Regular inspections and repairs can address any wear or damage to the refractory lining, ensuring optimal performance and minimal heat loss over time. In conclusion, monolithic refractories significantly contribute to the reduction of heat loss in iron and steel plants through their low thermal conductivity, excellent adhesion, and high strength. By effectively insulating equipment and preventing heat escape, these refractories promote energy efficiency and productivity in the iron and steel industry.

- Q: How do monolithic refractories contribute to the overall reliability of iron and steel processes?

- Monolithic refractories play a crucial role in enhancing the overall reliability of iron and steel processes in several ways. Firstly, they provide excellent thermal insulation, which helps in maintaining consistent and controlled temperatures within the furnaces and other equipment involved in the production process. This ensures the stability of the process and avoids any sudden temperature fluctuations that could lead to equipment failure or product quality issues. Secondly, monolithic refractories offer high resistance to thermal shocks and mechanical stresses, which are common in iron and steelmaking operations. These refractories can withstand extreme temperatures, rapid heating and cooling cycles, and the corrosive nature of molten metals, thereby prolonging the lifespan of the equipment and reducing the frequency of repairs or replacements. Moreover, monolithic refractories have a superior ability to resist chemical attacks from molten metals, slag, and other harsh substances encountered in iron and steel processes. This resistance prevents the refractories from deteriorating or corroding over time, ensuring their integrity and preventing any contamination of the metal being produced. Lastly, the use of monolithic refractories allows for greater design flexibility and ease of installation compared to traditional brick refractories. This flexibility enables the construction of complex shapes and structures, optimizing the efficiency and productivity of iron and steelmaking processes. Overall, monolithic refractories contribute significantly to the reliability of iron and steel processes by providing excellent thermal insulation, resistance to thermal shocks and chemical attacks, and facilitating flexible design and installation options.

- Q: How do monolithic refractories contribute to the reduction of emissions in iron and steel plants?

- The role of monolithic refractories in iron and steel plants is crucial for reducing emissions and addressing environmental challenges. These refractories are utilized to line the high-temperature areas of furnaces, including blast furnaces and electric arc furnaces, which are vital for the production processes of iron and steel. The exceptional thermal insulation properties of monolithic refractories help to minimize heat loss and enhance energy efficiency. This reduction in heat loss translates to lower energy consumption and emissions as less fuel is required to maintain the desired temperature. Furthermore, monolithic refractories contribute to emissions reduction by optimizing the combustion process. Their ability to withstand extreme temperatures and resist thermal shock ensures that the furnaces operate at their optimal conditions. This leads to more efficient combustion of fuels and raw materials, resulting in a decrease in the release of harmful gases and pollutants into the atmosphere. Additionally, these refractories possess excellent resistance to chemical attacks and corrosion, which is particularly important in iron and steel plants where aggressive substances like molten metal, slag, and gases are present. By providing a protective lining, they prevent the degradation of furnace walls and equipment, reducing the risk of leaks and emissions. Moreover, monolithic refractories find application in the construction of pollution control devices such as flue gas desulfurization systems and baghouses. These systems are designed to capture and remove pollutants from the flue gases generated during iron and steel production. The use of refractories in these systems ensures their durability and longevity, enabling them to efficiently and effectively reduce emissions. In summary, monolithic refractories play a vital role in reducing emissions in iron and steel plants by improving energy efficiency, optimizing combustion, providing corrosion resistance, and supporting pollution control systems. Their implementation allows the industry to minimize its environmental impact and transition towards more sustainable and responsible production processes.

- Q: What are the key factors affecting the installation and curing of monolithic refractories?

- There are several key factors that affect the installation and curing of monolithic refractories: 1. Material selection: The choice of monolithic refractory material is crucial as it determines the installation and curing process. Different materials have different installation and curing requirements, so it is important to select the right material for the specific application. 2. Surface preparation: Proper surface preparation is essential for the successful installation and curing of monolithic refractories. The surface should be clean, free from contaminants, and properly roughened to ensure good adhesion of the refractory material. 3. Mixing and proportioning: The mixing and proportioning of the refractory material play a significant role in its installation and curing. It is important to follow the manufacturer's instructions for mixing ratios and ensure thorough mixing to achieve a homogeneous mixture. 4. Application technique: The technique used to apply the monolithic refractory material can greatly impact its installation and curing. Proper application techniques, such as gunning, casting, or ramming, should be employed to ensure uniformity and proper bonding with the substrate. 5. Temperature control: Temperature control during the installation and curing process is critical for the development of desired properties in the monolithic refractory. The curing process should be carried out at the recommended temperature, and any sudden temperature changes should be avoided to prevent thermal stresses. 6. Moisture content: The moisture content of the refractory material and the surrounding environment can affect its installation and curing. Excessive moisture can lead to shrinkage, cracking, or poor bonding, while insufficient moisture can hinder proper curing. It is important to maintain the optimum moisture content for the specific refractory material. 7. Curing time: The curing time required for monolithic refractories varies depending on the material and application. It is crucial to follow the recommended curing time to allow for proper strength development and dimensional stability. 8. Environmental conditions: Environmental factors, such as humidity, temperature, and air circulation, can influence the installation and curing of monolithic refractories. Suitable environmental conditions should be maintained to facilitate proper drying and curing. Overall, understanding and addressing these key factors can ensure the successful installation and curing of monolithic refractories, leading to improved performance and longevity of the refractory lining.

- Q: What are the factors to consider when selecting monolithic refractories for specific applications?

- When selecting monolithic refractories for specific applications, several factors need to be considered. These include the operating temperature, chemical composition of the material being processed, mechanical stresses, thermal cycling, and the presence of any corrosive or erosive agents. Additionally, the refractory's thermal conductivity, porosity, density, and its ability to resist thermal shock and spalling are crucial factors to take into account. The availability and cost of the refractory material, as well as the installation and maintenance requirements, should also be considered during the selection process.

- Q: How are monolithic refractories different from traditional refractory materials?

- Monolithic refractories are different from traditional refractory materials in several ways. Firstly, while traditional refractory materials are typically made from bricks, blocks, or tiles, monolithic refractories are composed of a single, continuous material. This means that they do not have any joints or seams, which can be a weak point in traditional refractory structures. Secondly, monolithic refractories are much easier to install compared to traditional refractory materials. They can be easily shaped and applied in situ, allowing for greater flexibility in design and construction. In contrast, traditional refractory materials require skilled labor and more time-consuming installation methods such as bricklaying. Furthermore, monolithic refractories offer improved thermal shock resistance. Due to their continuous structure, they can better withstand sudden changes in temperature without cracking or spalling. Traditional refractory materials, on the other hand, may be more susceptible to thermal shock damage. Another advantage of monolithic refractories is their ability to provide better insulation. Their composition often includes lightweight aggregates or insulating fibers, which help to reduce heat loss and improve energy efficiency. Traditional refractory materials, while still capable of providing insulation, may not offer the same level of thermal efficiency. Lastly, monolithic refractories have the advantage of being more cost-effective. Their ease of installation, reduced labor requirements, and improved thermal performance contribute to lower overall project costs compared to traditional refractory materials. In summary, monolithic refractories differ from traditional refractory materials in terms of their continuous structure, ease of installation, improved thermal shock resistance, better insulation properties, and cost-effectiveness. These characteristics make them a preferred choice in many industries where high-temperature applications and thermal insulation are required.

- Q: What are the common applications of monolithic refractories in blast furnaces?

- Monolithic refractories, also known as unshaped refractories, are widely used in blast furnaces due to their advantageous properties and versatile applications. Some common applications of monolithic refractories in blast furnaces include: 1. Furnace lining: Monolithic refractories are used to line the walls, hearth, and roof of blast furnaces. Their high thermal resistance and superior insulating properties help protect the furnace structure from extreme temperatures and thermal shocks. 2. Tuyere and taphole repair: Blast furnaces have tuyeres, which are nozzles that inject air or fuel into the furnace, and tapholes, which are openings used to tap molten iron or slag. Monolithic refractories are used to repair and maintain these critical components, as they can withstand the high temperatures and chemical reactions occurring in these areas. 3. Hot repair and maintenance: Blast furnaces undergo frequent repairs and maintenance due to the harsh operating conditions. Monolithic refractories are used for hot repair and maintenance, as they can be easily applied in a plastic or semi-plastic state to fill cracks, patch damaged areas, or replace worn-out linings. 4. Erosion and corrosion resistance: Blast furnace environments are highly corrosive due to the presence of molten iron, slag, and other molten materials. Monolithic refractories with high resistance to erosion and corrosion are used to protect the furnace lining from chemical attacks and prolong its lifespan. 5. Gunning mixes: Gunning mixes are widely used in blast furnaces for their ability to be sprayed or gunned onto the refractory lining. These mixes consist of fine refractory aggregates, bonding agents, and additives. They are applied to repair worn-out areas, seal cracks, and provide a protective layer against erosion and slag penetration. 6. Slag line and iron runner repair: The slag line and iron runners in blast furnaces are prone to erosion and wear due to the corrosive nature of molten slag and iron. Monolithic refractories are used to repair and rebuild these areas, ensuring smooth and efficient operation of the furnace. In conclusion, monolithic refractories have various applications in blast furnaces, including furnace lining, tuyere and taphole repair, hot repair and maintenance, erosion and corrosion resistance, gunning mixes, and slag line and iron runner repair. Their ability to withstand high temperatures, chemical attacks, and mechanical stresses make them indispensable in maintaining the integrity and efficiency of blast furnace operations.

Send your message to us

Monolithic Refractories Ceramic Lined Ceramic Ball Valve for Iron and Steel Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords