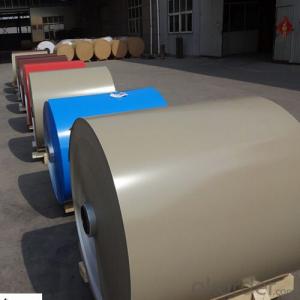

Self Adhesive Aluminum Sheets 12x12 Mirror Five Bars Embossed Aluminum Sheet Coil for Tread Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.General Information

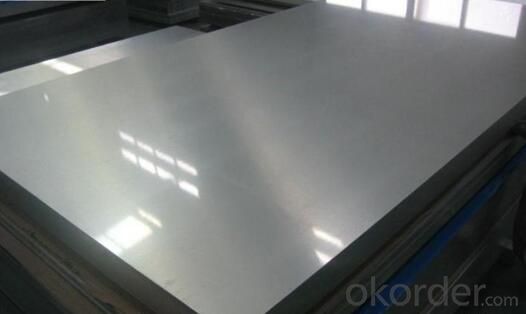

Aluminum sheets is between 0.1 mm and 500mm in thickness and has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

We produces aluminum sheets which meets the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. Our aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

The main producing procedure includes the following steps:

Rolling--Annealing--Slitting--Sawing, Cut-To-Length, Shearing

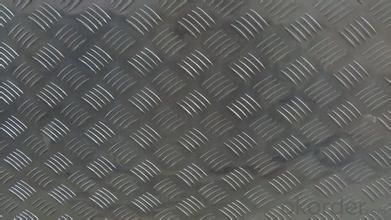

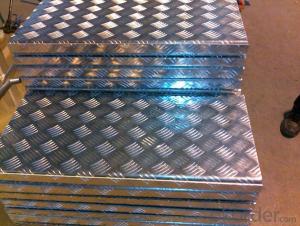

2.Structure of Embossed Aluminum Sheets for Different Usages

Our Embossed Aluminum Sheets for Different Usages have different patterns including diamond, stucco, big five bars, small five bars, etc.

Embossed Aluminum Sheets for Different Usages are widely used in decorative purchase in construction, packing and appliance. They are also very popularly used in anti-slippery purchase in vehicles and public places.

3.Main Features of Embossed Aluminum Sheets for Different Usages

High intensity

Easy to be processed and shaped

Weather resistance

Anti-pollution & environment protection

- Q: What are the environmental benefits of using aluminum sheets?

- There are several environmental benefits of using aluminum sheets. Firstly, aluminum is a highly recyclable material, meaning that it can be reused repeatedly without losing its quality. This reduces the need for mining and extraction of new aluminum, conserving natural resources and minimizing the environmental impact of the production process. Additionally, aluminum has a lower carbon footprint compared to other metals, as it requires less energy to produce. Moreover, aluminum is lightweight, which reduces fuel consumption during transportation, leading to lower greenhouse gas emissions. Overall, using aluminum sheets helps in promoting a more sustainable and eco-friendly approach to manufacturing and construction.

- Q: How does the surface cleanliness of aluminum sheet affect its adhesion properties?

- The surface cleanliness of aluminum sheet has a significant impact on its adhesion properties. The presence of contaminants, such as dirt, grease, or oxide layers, on the surface can hinder the ability of adhesives to bond effectively with the aluminum sheet. A clean and properly prepared surface is essential for achieving strong adhesive bonds. When the aluminum sheet is free from contaminants, the adhesive can spread evenly and make intimate contact with the surface, resulting in a stronger bond. On the other hand, if the surface is not clean, the adhesive may not be able to adhere properly, leading to weak or unreliable bonds. In addition to contaminants, the presence of oxide layers on the aluminum surface can also affect adhesion properties. Aluminum naturally forms an oxide layer when exposed to air, which can hinder adhesive bonding. This oxide layer needs to be removed or modified to ensure good adhesion. Surface preparation methods like cleaning, degreasing, and treating with chemical solutions can help remove or modify the oxide layer, allowing for better adhesion. Various surface cleaning techniques can be employed to improve the cleanliness and adhesion properties of aluminum sheets. These can include mechanical cleaning methods such as abrasive cleaning or sanding, solvent cleaning, acid etching, or even plasma cleaning. Each method is selected based on the type and extent of contamination present on the surface. In summary, the surface cleanliness of aluminum sheet directly affects its adhesion properties. A clean and properly prepared surface ensures better adhesion by allowing the adhesive to make intimate contact with the aluminum sheet. Therefore, it is crucial to consider and address surface cleanliness when attempting to achieve strong and reliable adhesive bonds with aluminum sheets.

- Q: This question asks if aluminum sheets can be recycled repeatedly without losing their quality.

- <p>Yes, aluminum sheets can be recycled multiple times without losing their quality. Aluminum is a highly recyclable material, and the recycling process does not degrade the material's properties. In fact, recycled aluminum requires significantly less energy to produce compared to mining and refining new aluminum from bauxite ore. This makes aluminum recycling an environmentally friendly and cost-effective process, contributing to sustainability and reducing the demand for raw materials.</p>

- Q: I have a specific design I'd like to cut out of thin sheet metal (aluminum or tin) and I'm wondering how to make it more sturdy. The sheet metal is a bit flimsy. Can I strengthen it by heating it up (butane torch) and cooling it quickly?

- This Site Might Help You. RE: Can you temper aluminum or tin? I have a specific design I'd like to cut out of thin sheet metal (aluminum or tin) and I'm wondering how to make it more sturdy. The sheet metal is a bit flimsy. Can I strengthen it by heating it up (butane torch) and cooling it quickly?

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of a building?

- <p>Yes, aluminum sheets can be used for exterior siding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum siding is lightweight, easy to install, and can be painted to match various architectural styles. It is also resistant to harsh weather conditions and pests, making it a popular choice for many homeowners and builders. However, it is important to ensure proper installation to maximize its benefits and longevity.</p>

- Q: This question asks for a list of adhesive types that are suitable for bonding aluminum sheets. It is important to provide a variety of options to give a comprehensive answer.

- <p>There are several types of adhesives used for bonding aluminum sheets together, including epoxy resins, which offer strong adhesion and resistance to heat and chemicals; polyurethane adhesives, known for their flexibility and durability; acrylic adhesives, which provide good adhesion and are easy to use; cyanoacrylates or 'super glues,' which bond quickly and are great for small, precise applications; and silicone adhesives, which are excellent for high-temperature applications and offer flexibility. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, and resistance to environmental factors.</p>

- Q: after putting aluminum sheet into the area between magnet and iron products, could magnet attract iron again?

- magnet can attract iron if the aluminum sheet isn't too thick. Because aluminum can't cut off magnetic line of force, unless aluminum sheet's thickness surpass the range of magnetic attraction.

- Q: Can aluminum sheet be used for reflective surfaces?

- Yes, aluminum sheet can be used for reflective surfaces.

- Q: My new home has a mix of copper and aluminum wiring. My mother used a shop vac in one of the recepticles last week and blew two of them in my bedroom. Then this weekend my brother was replacing my exhaust fan in the bathroom and that proceeded to blow the entire bedroom and bathroom including ceiling fans, lights and all recepticles. Does anyone have any ideas?

- It is very common in older homes to have tin coated copper wiring which many people then think they have aluminum wiring. If you have a piece of the older wiring or can turn the breaker off to one of these wires use a screw driver to scrape at the wire on the bare end; if it's tin coated copper you will see the orange/rust color of copper after a few light scrapes, the scaping is nothing agressive. This will determine if you have aluminum or not. Someone else mentioned about a loose connection which if a copper wire aluminum wire are connected together it would very likely fail creating a short. The two different materials expand contract at different rates which creates a bad connection. There is a special crimp process that can be done to join the two but a electrician should definately do this. A lot of the older homes just have two many items all on one breaker. With what you've described I would suggest using a electrician. Additional: If no breakers are tripped off and you do not have power in some areas you might have another panel (sub-panel) somewhere else in the home OR this circuit is hooked up to a GFI outlet somewhere else such as the kitchen, bathroom or garage. I would physically re-check each breaker and then hunt for a GFI outlet and sub-panel.

- Q: what were the cinergy field (riverfront stadium, cincinnati, oh) seats made of? were they metal or aluminum? i know they were silver under the red paint...

- If Cinergy isn't the concentration of the drawing, it particularly is probable in simple terms th at they have not as much as date the drawing of the skyline. If there's an indicator on the packaging layout, then removing the stadium might require them to resubmit the trademark utility, and that they probable do no longer evaluate it relatively easily worth the difficulty.

Send your message to us

Self Adhesive Aluminum Sheets 12x12 Mirror Five Bars Embossed Aluminum Sheet Coil for Tread Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords