Mill Finished EN AW-1200 Aluminum Sheets Los Angeles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished EN AW - 1200 Aluminium Sheet Description

Mill Finished EN AW - 1200 Aluminium Sheet is one semi-finished aluminium material. It is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished EN AW - 1200 Aluminium Sheet

Mill Finished EN AW - 1200 Aluminium Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished EN AW - 1200 Aluminium Sheet

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished EN AW - 1200 Aluminium Sheet

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished EN AW - 1200 Aluminium Sheet

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

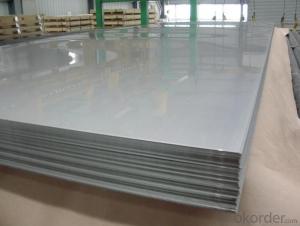

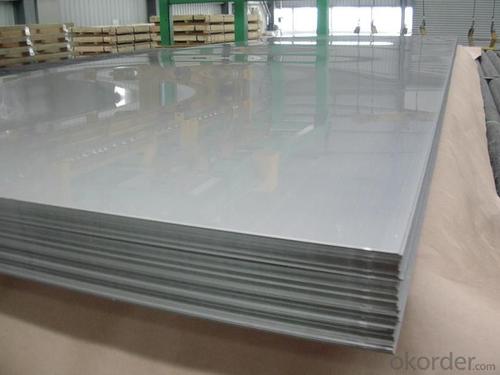

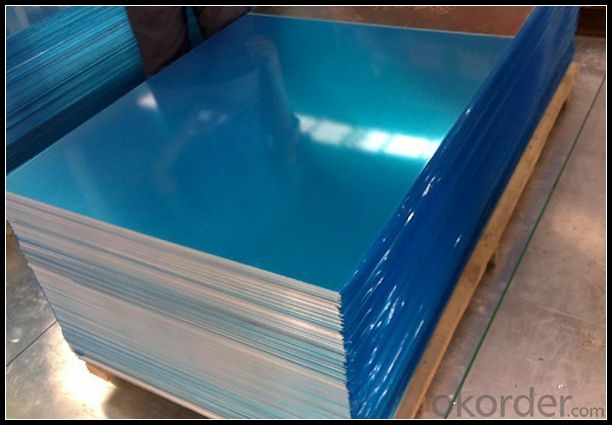

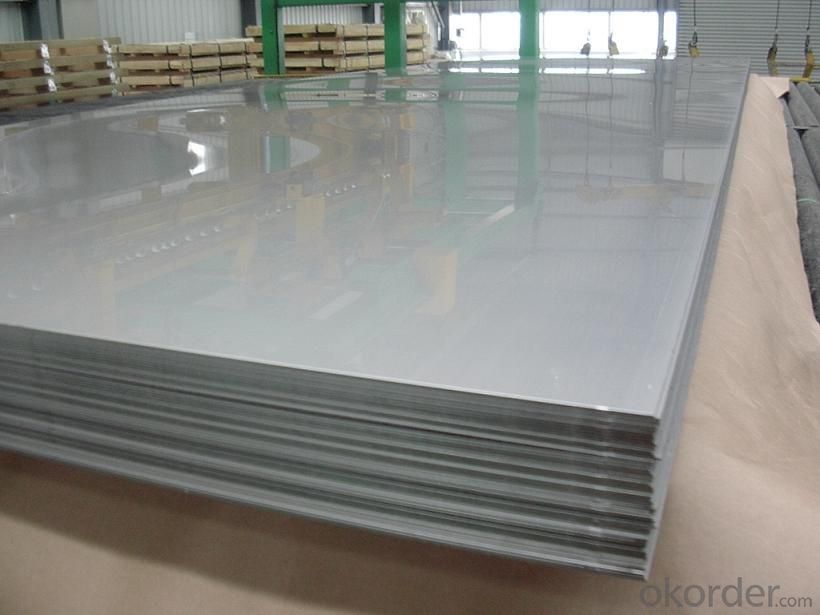

6. Image of Mill Finished EN AW - 1200 Aluminium Sheet

7. Package and shipping of Mill Finished EN AW - 1200 Aluminium Sheet

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: The question asks about the duration aluminum sheets can last and how this compares to the lifespan of other materials.

- <p>The lifespan of aluminum sheets can vary significantly based on the environment and usage conditions. Generally, aluminum sheets have a long lifespan, often lasting 50 years or more without significant deterioration when properly maintained. This durability makes aluminum sheets a popular choice for construction and manufacturing applications. Compared to other materials, such as steel, aluminum is lighter and more resistant to corrosion, which can extend its lifespan in certain environments. However, steel may be more suitable for applications requiring high strength, while aluminum excels in applications where weight and corrosion resistance are priorities.</p>

- Q: How do aluminum sheets perform in terms of wear resistance?

- Due to their inherent properties and surface characteristics, aluminum sheets generally exhibit good wear resistance. They are lightweight yet durable, boasting a high strength-to-weight ratio, which makes them suitable for various applications that require wear resistance. To further enhance the wear resistance of aluminum sheets, various methods can be employed. Alloying, heat treatment, and surface treatments are among the techniques that can be utilized. By incorporating elements like copper, magnesium, or zinc into aluminum, its hardness and wear resistance can be improved. Heat treatment processes such as precipitation hardening can also bolster the strength and wear resistance of aluminum sheets. Moreover, the wear resistance of aluminum sheets can be significantly enhanced through surface treatments such as anodizing or the application of protective coatings. Anodizing forms a protective oxide layer on the surface of aluminum, providing increased resistance to abrasion, corrosion, and wear. Coatings like powder coatings or paint can also serve as an additional layer of protection against wear and tear. In various industries such as automotive, aerospace, construction, and marine, aluminum sheets find widespread use due to their excellent wear resistance. They are commonly employed in components that undergo sliding, rubbing, or impact, such as panels, body parts, and structural elements. While aluminum sheets may not possess the same level of wear resistance as certain steel alloys or other specialized materials, they offer a favorable balance between strength, weight, and wear resistance. Through appropriate alloying, heat treatment, and surface treatments, aluminum sheets can provide satisfactory wear resistance across a wide range of applications.

- Q: how to avoid oxidation of aluminum sheet after wire drawing?

- leave it alone after wire drawing!aluminum sheet will formulate a layer of dense oxide film. So you don't need to worry about it! Don't often polish the aluminum wire, or they will be more and more slimsy, the oxide film is used for avoiding reoxidation.

- Q: Can aluminum sheet be used for architectural applications?

- Yes, aluminum sheet can be used for architectural applications. It is a versatile material that offers durability, lightweight properties, and corrosion resistance, making it suitable for various architectural projects such as facades, roofing, window frames, and decorative elements. Additionally, aluminum can be easily formed, fabricated, and finished to meet specific design requirements, making it a popular choice in the construction industry.

- Q: Are the aluminum sheets suitable for signage or advertising purposes?

- Aluminum sheets are an excellent choice for signage and advertising purposes due to their high suitability. The versatility and durability of aluminum make it resistant to rust, corrosion, and weathering, which is ideal for outdoor use. Furthermore, its lightweight nature facilitates effortless installation and transportation, while the smooth surface adds a touch of professionalism and sophistication. The customizable nature of aluminum sheets allows for easy cutting, shaping, and engraving, enabling designers to create captivating signs and advertisements. Additionally, aluminum sheets can be directly printed on or laminated with vinyl to achieve vibrant and long-lasting graphics. In summary, the remarkable properties of aluminum make it the perfect material for signage and advertising purposes.

- Q: What specific coatings or treatments are required for aluminum sheets to enhance their properties or protect them?

- <p>Special coatings or treatments for aluminum sheets may be needed depending on the application. Anodizing is a common treatment that enhances corrosion resistance and wear. For aesthetic purposes, aluminum can be painted or coated with a clear lacquer to maintain its appearance. Protective coatings like powder coating or electroplating can be used to improve durability and resistance to environmental factors. In certain industrial applications, aluminum sheets may be treated with specific coatings to enhance thermal or electrical conductivity. The choice of coating or treatment depends on the specific requirements of the project, such as resistance to weather, chemicals, or mechanical stress.</p>

- Q: what's the difference between zinc sheet and aluminum sheet?

- Only zinc sheet can react, zinc is amphoteric.

- Q: I found a baby dish at a yard sale and all it says on the bottom is Lydney Aluminum PRODUCTS FOR BETTER LIVING. It appears old. Thanks. I already checked google.

- Lydney Aluminum, I don't think that I have heard of them in the boating industry. T.

- Q: Are the aluminum sheets suitable for manufacturing power distribution panels?

- Yes, aluminum sheets are suitable for manufacturing power distribution panels. Aluminum is a lightweight and durable material with excellent electrical conductivity, making it ideal for use in power distribution systems. Additionally, it is highly resistant to corrosion, which is crucial for ensuring the longevity and reliability of the panels.

- Q: Hello,Does it matter what kind of wheel I use as a cut off wheel on an angle grinder when cutting aluminum?Thanks!

- Hello, If you are cutting aluminum you should use a metal cutting blade. A normal stone saw blade will not cut the metal safely. It will also be uneconomical. A metal cutting blade will cut much quicker than trying to force a stone blade through metal. It also matters because it can be dangerous cutting any metal with a blade that is not meant for cutting metal because the blade can become unstable and parts can come away from the blade. The cost of the cutting blades for both stone,brick,concrete etc and the cost of a metal blade will be somewhere similar in price so If i were you i would always look to buy a metal cutting blade rather than a general blade. Hope this helps.

Send your message to us

Mill Finished EN AW-1200 Aluminum Sheets Los Angeles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords