No-Mar Mill Finished Direct Casting Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished Direct Casting Aluminium Coil

Mill Finished Direct Casting Aluminium Coil is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Direct Casting Aluminium Coil

Mill Finished Direct Casting Aluminium Coil | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished Direct Casting Aluminium Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Direct Casting Aluminium Coil

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Direct Casting Aluminium Coil

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

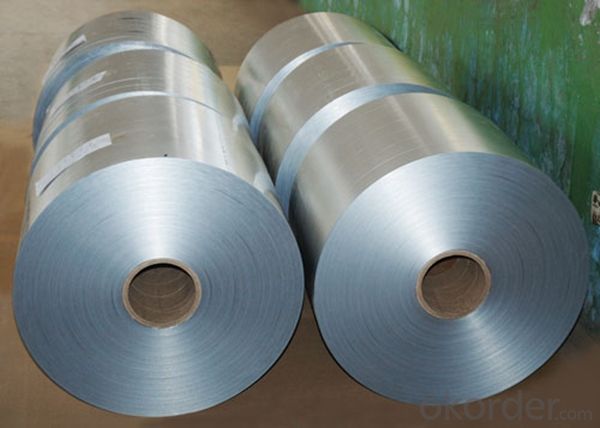

6. Image of Mill Finished Direct Casting Aluminium Coil

7. Package and shipping of Mill Finished Direct Casting Aluminium Coil

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are there any limitations on the width-to-thickness ratio of aluminum coils?

- Yes, there are limitations on the width-to-thickness ratio of aluminum coils. The width-to-thickness ratio is an important factor in determining the overall strength and performance of aluminum coils. If the ratio is too high, it can lead to issues such as buckling, warping, or even failure of the coil. The specific limitations on the width-to-thickness ratio depend on various factors such as the alloy composition, temper, and intended application of the aluminum coil. Different alloys and tempers have different mechanical properties and can handle different ratios. Additionally, the intended application of the coil, such as roofing, automotive, or packaging, may have specific requirements for the width-to-thickness ratio. Manufacturers typically provide guidelines and specifications for the acceptable width-to-thickness ratio based on their product offerings. These guidelines ensure that the coils are used within their intended capabilities and prevent any issues related to excessive width-to-thickness ratios. It is important for users and designers to consider these limitations and guidelines when selecting and utilizing aluminum coils. Failure to adhere to these limitations can result in compromised performance, increased risk of damage, and potential safety concerns. Therefore, it is crucial to consult the manufacturer's recommendations and industry standards to determine the appropriate width-to-thickness ratio for a given application.

- Q: I need to draw dot and cross diagrams to explain how they bond, but if the aluminium outer shell has 13 electrons and the oxygen one has 6, how do they all become happy atoms, and all have a full outer shell? please help! thank you.

- I really do not know so ask somebody else

- Q: How are aluminum coils cleaned before further processing?

- To guarantee the elimination of any contaminants or impurities, aluminum coils undergo a series of steps for cleaning prior to further processing. The cleaning process entails the utilization of chemical solutions and mechanical techniques. Initially, the coils are immersed in a degreaser or cleaning solution to dissolve and eradicate any oils, greases, or dirt present on the surface. This stage is essential in eradicating organic contaminants that may hinder subsequent processes. Following the soaking, the coils typically undergo a high-pressure water rinse to eliminate any remaining residues or particles. This step aids in dislodging and flushing out loosened contaminants from the coil surface. In certain instances, a combination of chemical cleaning and mechanical scrubbing or brushing may be employed to effectively eliminate stubborn or baked-on contaminants. This method is particularly beneficial for coils exposed to harsh environmental conditions or industrial processes. Once the coils have been cleaned, they are typically rinsed again to ensure complete removal of any cleaning agents or residues. This is crucial to prevent any adverse effects or interference with subsequent processing stages. Overall, the cleaning of aluminum coils prior to further processing plays a vital role in achieving high-quality end products. It ensures impurity removal, enhances the surface finish, and improves the overall performance and lifespan of the finished aluminum products.

- Q: How are aluminum coils protected against scratches and damage?

- Aluminum coils are protected against scratches and damage through several methods. One common method is the application of a protective coating or film on the surface of the coil. This coating serves as a barrier between the coil and any potential sources of damage, such as abrasion or impact. Another way to protect aluminum coils is by using a process called coil coating. In this process, the coil is cleaned, pre-treated, and coated with a layer of protective paint or resin. This coating not only enhances the appearance of the coil but also provides a protective layer against scratches and other forms of damage. Additionally, during the manufacturing and handling process, aluminum coils are often wrapped or packaged in materials that provide cushioning and protection. This helps to prevent any scratches or dents that may occur during transportation or storage. Lastly, proper handling and storage practices play a crucial role in protecting aluminum coils against scratches and damage. It is important to handle the coils with care, using appropriate equipment and techniques to minimize the risk of scratching or other forms of damage. Storing the coils in a clean and dry environment can also help prevent any potential damage. Overall, a combination of protective coatings, coil coating processes, proper handling, and storage practices ensures that aluminum coils are well-protected against scratches and damage, maintaining their quality and appearance.

- Q: What are the common fabrication techniques for aluminum coils?

- Aluminum coils can be fabricated using several common techniques, including rolling, annealing, slitting, and coating. The primary fabrication technique for aluminum coils is rolling. This involves passing a continuous strip of aluminum through a series of rollers to gradually reduce its thickness and increase its length. The process can be done hot or cold, depending on the desired properties of the coil. To improve the mechanical properties of aluminum coils, annealing is often used. This heat treatment process involves heating the coil to a specific temperature and then cooling it slowly to relieve internal stresses and increase its ductility. This makes the coil easier to work with during subsequent fabrication processes. For cutting wide aluminum coils into narrower strips, the technique of slitting is employed. This involves passing the coil through sharp rotating knives that make precise cuts along the length of the coil. Slitting allows for customization and the production of coils in different widths, which can be used for various applications. Coating is another commonly used fabrication technique for aluminum coils. It involves applying a protective or decorative coating onto the surface of the coil to enhance its appearance and improve its performance. Various types of coatings, such as paint, anodizing, and powder coating, provide corrosion resistance, durability, and aesthetic appeal. In summary, these fabrication techniques are essential in transforming aluminum into coils that meet specific requirements for industries like construction, automotive, and aerospace.

- Q: We have all heard the Us saying aluminum and their euro counterparts saying aluminium. I assumed this was just a small difference in culture or location. But, while reading my chemistry book (Chemistry the Central Science 12th) i came across a section saying: Cations formed from nonmetal atoms have names that end in -ium: NH4+ ammonIUM ion, H3O+ hydronIUM ion. So, i have came up with a hypothesis, could it be possible that when the periodic table was coming together, the aluminium was changed to aluminum to allow the rules to work? Thus making aluminum the correct spelling? Give me your thoughts.

- www.okorder ... aluminum (n.) 1812, coined by English chemist Sir Humphry Davy (1778-1829), from alumina, name given 18c. to aluminum oxide, from Latin alumen alum (see alum). Davy originally called it alumium (1808), then amended this to aluminum, which remains the U.S. word, but British editors in 1812 further amended it to aluminium, the modern preferred British form, to better harmonize with other metallic element names (sodium, potassium, etc.).

- Q: What are the potential health hazards associated with the use of old aluminum coils?

- <p>Using old aluminum coils can pose health risks due to potential leaching of aluminum into food or beverages. Long-term exposure to aluminum may lead to cognitive impairments and neurological issues. Additionally, old coils may have accumulated dirt, bacteria, or other contaminants that could cause infections or digestive problems. It's important to regularly inspect and replace aluminum cookware to ensure safety.</p>

- Q: Are aluminum coils compatible with other building materials?

- Yes, aluminum coils are compatible with other building materials. Aluminum is a versatile material that can be used in conjunction with various building materials such as steel, concrete, glass, and wood. It is commonly used in construction projects for roofing, cladding, and façade systems, as well as in HVAC and electrical applications. Aluminum's corrosion resistance and lightweight properties make it a preferred choice for integration with other building materials.

- Q: Can aluminum coils be used in food processing applications?

- Food processing applications can utilize aluminum coils, as they offer a range of advantages. Aluminum is a widely used and highly adaptable material in the food industry due to its various benefits. Aluminum coils are lightweight, durable, and possess excellent thermal conductivity, which makes them suitable for applications requiring efficient and uniform heat transfer. When it comes to food processing, aluminum coils are commonly employed in equipment such as heat exchangers, evaporators, and refrigeration units. These coils help to cool, heat, or maintain the temperature of different food products during their processing, storage, or transportation. The exceptional thermal conductivity of aluminum ensures that heat is evenly dispersed, thereby aiding in the preservation of food quality and flavor. Furthermore, aluminum is a non-toxic and non-reactive metal, meaning it has no adverse effects on the taste or composition of the processed food. It is also naturally resistant to corrosion, ensuring that the coils do not contaminate the food and can be easily cleaned and maintained. In addition, aluminum is an environmentally friendly and recyclable material, aligning with the increasing demand for sustainable practices in the food industry. Its lightweight nature also contributes to energy efficiency and reduced transportation expenses. In conclusion, aluminum coils are a reliable, efficient, and safe choice for food processing applications. They meet the strict requirements of the industry while ensuring the quality and safety of the processed food.

- Q: I know this question is not so bright, but I am very curious why do we recycle aluminum cans? Is it that they are not biodegradable?

- Aluminum is not biodegradable. Also making aluminum from ore requires a lot of energy. Recycling cans is easy and saves a whole lot of energy reducing green house gases. Recycling aluminum also reduces the mining required to dig up aluminum ore thereby saving the land and stopping pollution from mine run-off.

Send your message to us

No-Mar Mill Finished Direct Casting Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords