3/8 Aluminum Coil - Mill Finished Direct Casting Aluminum Circle AA1050

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of DC Aluminium in Coil Form for making Aluminium Circle Description

DC Aluminium in Coil Form for making Aluminium Circle is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Feature of DC Aluminium in Coil Form for making Aluminium Circle

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

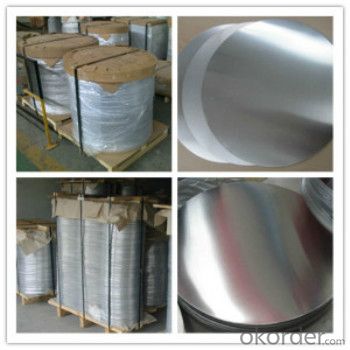

3. Image of DC Aluminium in Coil Form for making Aluminium Circle

4. Specification of DC Aluminium in Coil Form for making Aluminium Circle

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

5. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

4)What about payment term?

30% T/T in advance, balance against B/L COPY or 100% L/C AT SIGHT.

- Q: Are aluminum coils suitable for electrical conductivity?

- Yes, aluminum coils are suitable for electrical conductivity. Aluminum is a highly conductive metal and is widely used in electrical applications due to its excellent electrical conductivity properties. It is commonly used as a conductor in power transmission lines, electrical cables, and various electrical components.

- Q: What is color aluminum coil?

- The base plates are all aluminum, but the surface has been colored.

- Q: I have a muffin pan made of aluminum foil and I do not know if i can put it in the oven to cook some muffins. Many sights say it will melt but they say that about putting a sheet of foil at the bottom of the oven for a long time. I just want it to be in their for half an hour to make muffins.

- Aluminum melts at 1220 degrees F (or around 660 degrees C) [from Wikipedia]. If you are cooking anything at that temperature, you are crazy and have a monster oven. So yeah, no problem with that.

- Q: Can aluminum coils be used for electrical conductors?

- Yes, aluminum coils can be used for electrical conductors. Aluminum is a good conductor of electricity and is commonly used in various electrical applications due to its high conductivity, lightweight nature, and cost-effectiveness.

- Q: Are aluminum coils resistant to mold and mildew?

- Generally, aluminum coils have resistance to mold and mildew. Unlike materials like wood or fabric, aluminum is non-porous and does not absorb moisture. This characteristic reduces its susceptibility to mold and mildew growth. Moreover, protective finishes are often applied to aluminum coils, enhancing their resistance to mold and mildew. Nevertheless, it is important to remember that although aluminum coils are less prone to mold and mildew, they are not entirely immune. If exposed to excessive moisture or humidity, mold and mildew can still develop. Thus, regular cleaning and maintenance are essential to prevent potential mold or mildew growth.

- Q: Is it possible to utilize aluminum coils in the construction of solar panels or wind turbines?

- <p>Aluminum coils can be used in the construction of both solar panels and wind turbines, but not as the primary material for energy conversion. In solar panels, aluminum is often used for framing and mounting structures due to its lightweight and corrosion-resistant properties. For wind turbines, aluminum is utilized in the manufacturing of certain components such as nacelle shells and towers, but the main rotor blades are typically made from composite materials for their strength and aerodynamic properties. Thus, while aluminum plays a supportive role in these renewable energy technologies, it is not the core material for capturing solar or wind energy.</p>

- Q: This question asks about the environmental effects that aluminum coils may have on the environment.

- <p>The environmental impacts of aluminum coils are multifaceted. Aluminum production, particularly the extraction and refining process, consumes significant energy and can result in greenhouse gas emissions. The mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. However, aluminum coils are recyclable, which reduces their environmental footprint compared to non-recyclable materials. When recycled, aluminum saves up to 95% of the energy needed to produce new aluminum, reducing emissions and waste. Despite these benefits, improper disposal or incineration of aluminum can still contribute to pollution. Overall, the environmental impact of aluminum coils is complex, with both negative and positive aspects depending on production methods and waste management practices.</p>

- Q: Can aluminum coils be used in the production of lighting fixtures?

- Yes, aluminum coils can be used in the production of lighting fixtures. Aluminum is a lightweight and durable material that is commonly used in various industrial applications, including lighting fixtures. It offers excellent heat dissipation properties, making it suitable for housing and cooling components in lighting fixtures. Additionally, aluminum coils can be easily shaped and formed to create different designs and sizes of fixtures, making them a versatile choice for manufacturers.

- Q: Is it possible to use a welding process to join two pieces of aluminum coil?

- <p>Yes, you can weld two pieces of aluminum coil together, but it requires specific techniques and equipment. Aluminum welding is different from steel welding and requires a TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding process. It's crucial to use a clean, dry aluminum filler rod and maintain a clean, oxide-free surface on the aluminum. Additionally, a shielding gas like argon is necessary to protect the weld area from oxidation. Special precautions must be taken due to aluminum's high thermal conductivity and reactivity, so it's recommended to have experience or professional guidance when welding aluminum.</p>

- Q: How do aluminum coils contribute to thermal management?

- The exceptional heat transfer capabilities of aluminum coils are crucial in thermal management. Aluminum possesses a high thermal conductivity, allowing it to efficiently transfer heat from one area to another. This quality plays a vital role in applications that require effective thermal management, including air conditioning systems, refrigeration units, and heat exchangers. In air conditioning systems, aluminum coils are commonly employed in the condenser and evaporator coils. The condenser coil releases heat from the refrigerant to the surrounding air, while the evaporator coil absorbs heat from the indoor air to cool it down. The high thermal conductivity of aluminum ensures efficient heat transfer between the refrigerant and the surrounding air, resulting in faster and more effective cooling. Similarly, refrigeration units utilize aluminum coils in the evaporator coils to extract heat from the interior space. The aluminum coils assist in removing heat from the refrigerated area and transferring it to the outside environment, maintaining a lower temperature inside the unit. Heat exchangers, which are utilized in various industries like automotive, power generation, and HVAC, also benefit from aluminum coils. Heat exchangers are devices that transfer heat between multiple fluids with different temperatures. Aluminum's high thermal conductivity enables efficient heat exchange between the fluids, enhancing overall system performance and energy efficiency. Furthermore, aluminum coils possess lightweight properties and are resistant to corrosion, making them durable and suitable for long-term use in harsh environments. These characteristics further contribute to effective thermal management by ensuring reliable heat transfer and reducing the risk of system failure or decreased efficiency. In conclusion, aluminum coils play a crucial role in thermal management systems by facilitating efficient heat transfer, expediting cooling or heating processes, and improving overall system performance. Their high thermal conductivity, lightweight nature, and corrosion resistance make them the preferred choice in various applications requiring effective thermal management.

Send your message to us

3/8 Aluminum Coil - Mill Finished Direct Casting Aluminum Circle AA1050

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords