Mill Finished Aluminum Treadplate for Gas Tank Transportation - Aluminum Sheets for Sale Toronto

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished Aluminium Treadplatefor Gas Tank Transportation Description

Mill Finished Aluminium Sheet for Gas Tank Transportation is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Aluminium Treadplate for Gas Tank Transportation

Mill Finished Aluminium Sheet for Gas Tank Transportation | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished Aluminium Treadplate for Gas Tank Transportation

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Aluminium Treadplate for Gas Tank Transportation

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Aluminium Treadplate for Gas Tank Transportation

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

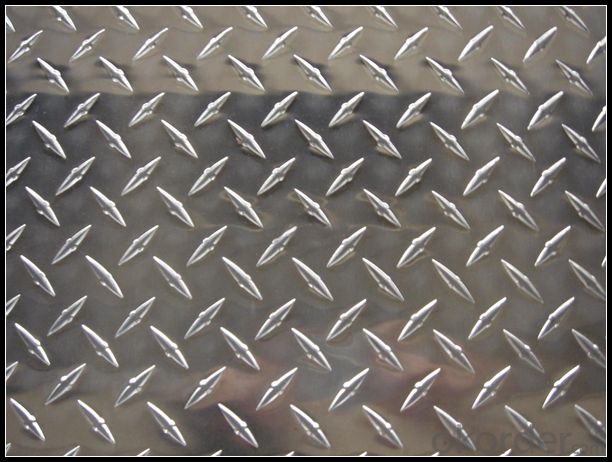

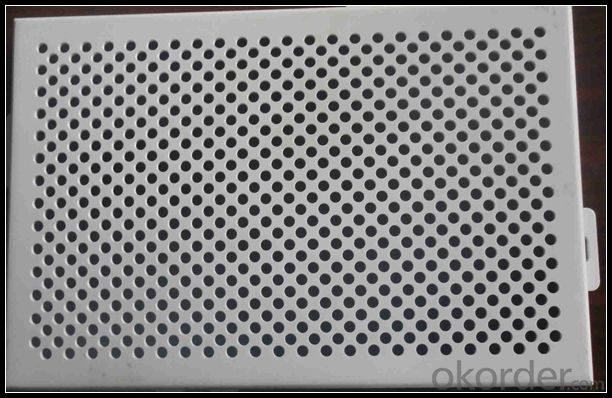

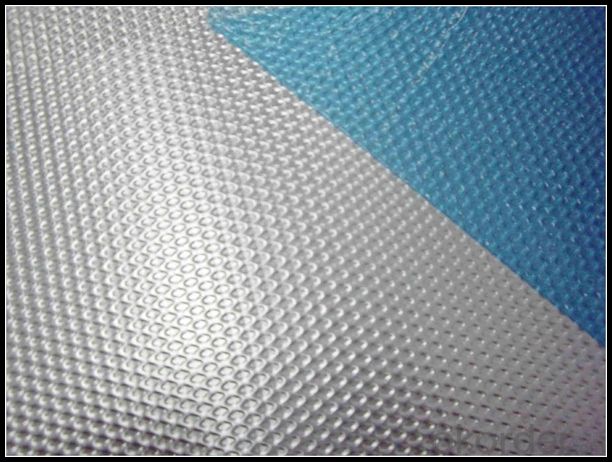

6. Image of Mill Finished Aluminium Treadplate for Gas Tank Transportation

7. Package and shipping of Mill Finished Aluminium Sheet for Gas Tank Transportation

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do you prevent scratches during transportation of aluminum sheets?

- To prevent scratches during transportation of aluminum sheets, it is important to use protective measures such as wrapping the sheets in a cushioning material like foam or bubble wrap. Additionally, using appropriate packaging techniques such as stacking the sheets securely and avoiding any direct contact with sharp or abrasive objects can help minimize the risk of scratches.

- Q: Are aluminum sheets suitable for insulation and soundproofing?

- Yes, aluminum sheets can be suitable for insulation and soundproofing purposes. Aluminum is a lightweight, durable, and highly reflective material that can effectively block heat and sound transmission. When used as insulation, aluminum sheets can act as a radiant barrier, reflecting heat away from the insulated space and helping to maintain a comfortable temperature. Furthermore, aluminum sheets can also be used as a soundproofing material to reduce the transmission of noise. The dense structure of aluminum helps to absorb and dampen sound waves, making it an effective solution for minimizing noise pollution. Additionally, aluminum sheets are resistant to corrosion and moisture, making them suitable for both indoor and outdoor applications. Overall, aluminum sheets provide a cost-effective and efficient solution for insulation and soundproofing needs.

- Q: What are the different surface finishes available for aluminum sheets?

- There are several different surface finishes available for aluminum sheets, each offering distinct characteristics and aesthetic appeal. Some of the commonly used surface finishes for aluminum sheets include: 1. Mill Finish: This is the most basic surface finish and is achieved by leaving the aluminum in its as-rolled condition, without any additional treatment. It has a smooth and shiny appearance, but may have minor imperfections and is not as durable as other finishes. 2. Anodized Finish: Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum sheet. This finish enhances corrosion resistance, improves durability, and provides a wide range of color options. Anodized finishes can have a matte or glossy appearance. 3. Brushed Finish: This finish is achieved by brushing the aluminum sheet with a fine abrasive material, creating a textured pattern. This finish is commonly used for decorative purposes and provides a unique and attractive appearance. 4. Polished Finish: Polishing the aluminum sheet using abrasive materials creates a smooth and reflective surface. This finish is often used for decorative purposes and gives a high-end, mirror-like appearance to the aluminum. 5. Embossed Finish: Embossing is a process that creates raised or recessed patterns on the surface of the aluminum sheet. This finish is commonly used for decorative purposes, as it adds texture and visual interest to the material. 6. Powder Coated Finish: Powder coating involves applying a dry powder to the aluminum sheet and then curing it under heat. This finish provides a durable and weather-resistant coating, and is available in a wide range of colors and textures. 7. Patterned Finish: Patterned finishes are achieved by imprinting different patterns or designs on the surface of the aluminum sheet. This finish is often used for architectural applications and adds visual interest to the material. These are just a few examples of the different surface finishes available for aluminum sheets. The choice of finish depends on the desired appearance, functionality, and application requirements.

- Q: Can aluminum sheet be used for solar panels?

- Absolutely! When it comes to solar panels, aluminum sheet is a fantastic choice. Thanks to its remarkable strength, durability, and lightweight nature, aluminum is a widely favored material for constructing these panels. Its versatility shines through as it serves as both the frame and mounting structure, providing unparalleled support and stability. Moreover, its exceptional resistance to corrosion is a crucial factor given the panels' exposure to the elements. On top of all that, aluminum's highly conductive properties allow for efficient electricity transfer from the solar cells within the panel. All in all, incorporating aluminum sheet into solar panel construction significantly enhances their performance, longevity, and overall efficiency.

- Q: Can aluminum sheets be used for boat building?

- Yes, aluminum sheets can be used for boat building. Aluminum is a popular material choice due to its strength, durability, and resistance to corrosion. It is lightweight and easy to work with, making it suitable for constructing various types of boats. Additionally, aluminum boats are known for their longevity and low maintenance requirements.

- Q: This question asks about the impact of aluminum sheets on the air quality inside a building.

- <p>Aluminum sheets themselves do not directly affect indoor air quality. They are inert materials that do not emit volatile organic compounds (VOCs) or other harmful substances. However, the installation process might involve adhesives or sealants that could release VOCs temporarily. Proper ventilation during and after installation can mitigate this issue. Additionally, aluminum sheets can contribute to better air quality by enhancing thermal performance, reducing energy consumption for heating and cooling, and indirectly lowering emissions from power plants.</p>

- Q: Is it possible to substitute aluminum sheets for wood siding in construction?

- <p>Yes, you can use aluminum sheets to replace wood siding. Aluminum siding is a popular alternative to wood for several reasons. It is lightweight, durable, and resistant to rot, insects, and moisture. It also requires less maintenance than wood and can be painted to match various aesthetic preferences. However, it's important to consider factors such as insulation properties, cost, and the look you want to achieve, as aluminum may not perfectly mimic the appearance of wood. Always consult with a professional to ensure proper installation and compatibility with your home's architecture.</p>

- Q: How do you determine the thickness tolerance of an aluminum sheet?

- One way to determine the thickness tolerance of an aluminum sheet is by referring to the industry standards or specifications for aluminum sheet thicknesses. These standards outline the acceptable range of thickness variations and provide tolerance values. Additionally, using precision measuring tools such as micrometers or calipers, you can directly measure the thickness at various points on the sheet and compare it to the specified tolerance range to determine if it meets the required thickness tolerance.

- Q: What is the fatigue life of aluminum sheets?

- The endurance capacity of aluminum sheets pertains to the number of cycles the material can endure before failure arises under cyclic loading circumstances. Various factors, including the composition, thickness, surface finish, loading conditions, and environmental elements, can cause the endurance capacity of aluminum sheets to differ. Aluminum is renowned for its relatively high fatigue strength in comparison to other materials, rendering it a favored option in industries like aerospace, automotive, and construction. The endurance capacity of aluminum sheets is typically influenced by the presence of microstructural flaws, such as inclusions, voids, and grain boundaries. Fatigue tests are conducted, utilizing standardized procedures like ASTM E466 or ASTM E606, to ascertain the endurance capacity of aluminum sheets. These tests entail subjecting the material to cyclic loading conditions, usually at a consistent stress or strain amplitude, while monitoring the number of cycles required for failure to arise. The outcomes are then employed to generate an S-N curve, which represents the connection between the applied stress or strain amplitude and the number of cycles until failure. The S-N curve furnishes valuable insights into the endurance capacity of aluminum sheets, indicating the stress or strain levels at which the material can withstand a specific number of cycles before failure. It is crucial to note that the endurance capacity of aluminum sheets can be enhanced through various approaches, such as alloying, heat treatment, surface treatment, and appropriate design considerations. To conclude, the endurance capacity of aluminum sheets plays a pivotal role in the design of components or structures exposed to cyclic loading conditions. By comprehending the specific properties and characteristics of the aluminum alloy, coupled with proper testing and analysis, it is possible to ascertain the endurance capacity and guarantee the safe and dependable performance of aluminum sheets in diverse applications.

- Q: What unique cleaning techniques should be employed when cleaning aluminum sheets?

- <p>Yes, there are special cleaning methods for aluminum sheets. It's important to use a gentle, non-abrasive cleaner to avoid scratching the surface. Avoid using harsh chemicals or abrasive materials that can damage the aluminum. Instead, use a soft cloth or sponge with a mild detergent solution. Rinse thoroughly with water to remove any cleaning residue, as some detergents can leave a film on the aluminum. Dry the aluminum sheet immediately after rinsing to prevent water spots. Regular cleaning can help maintain the appearance and longevity of aluminum sheets.</p>

Send your message to us

Mill Finished Aluminum Treadplate for Gas Tank Transportation - Aluminum Sheets for Sale Toronto

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords