Mill Finished Aluminum Strips for Cooling - Aluminum Sheets for Sale in NJ

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

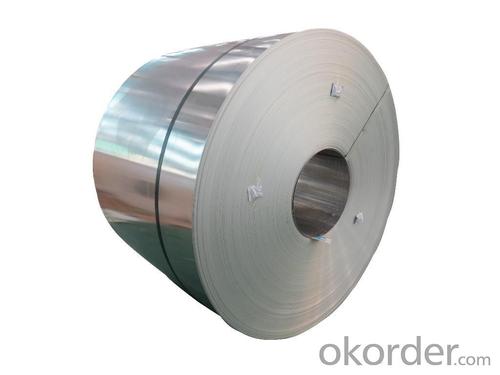

1.Structure of Mill Finished Aluminium Strips for Coolling

Mill Finished Aluminium Strips for Color Coated Ceilling for Deep Drawing Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Mill Finished Aluminium Strips for Coolling

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Mill Finished Aluminium Strips for Coolling

4. Product Specification of Mill Finished Aluminium Strips for Coolling

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can 101 aluminum sheets be used in the production of consumer electronics?

- Yes, 101 aluminum sheets can be used in the production of consumer electronics. Aluminum is a lightweight and durable material that is commonly used in various electronic devices, including smartphones, laptops, and tablets. The specific grade of aluminum, such as 101, determines its properties and suitability for different applications.

- Q: If one were to hit someone with a baseball bat, would it cause more pain to use a wooden bat or an aluminum one? Just wondering.

- While I fortunately have not been hit with either, I would think the wooden bat, with its increased weight, could be swung more forcefully and would hurt more.

- Q: This question asks about the various color options available for aluminum sheets.

- <p>Aluminum sheets are available in a wide range of colors to suit various applications and aesthetic preferences. Common colors include silver (anodized), white, black, and clear (natural). Beyond these, there are also options for colors like red, blue, green, and yellow. Some manufacturers offer custom color matching services for specific projects. Additionally, aluminum sheets can be coated with various finishes such as matte, gloss, or textured, further expanding the color and appearance options. It's important to check with specific suppliers for their available color range as it can vary.</p>

- Q: Can the aluminum sheets be bent or formed into different shapes?

- Yes, aluminum sheets can be easily bent or formed into different shapes due to their malleability and ductility.

- Q: Can aluminum sheets be used for wall cladding?

- Indeed, wall cladding can utilize aluminum sheets. The lightweight quality, durability, and resistance to corrosion make aluminum a favored option for cladding materials. It is frequently employed in both commercial and residential constructions to enhance the external appearance of a structure with an appealing and contemporary aesthetic. The malleability and ease of fabrication of aluminum sheets enable the creation of diverse shapes and sizes, facilitating flexible design possibilities. Furthermore, aluminum cladding demands minimal maintenance, necessitating only sporadic cleaning and upkeep. In summary, aluminum sheets are a versatile and pragmatic selection for wall cladding.

- Q: i want to build a smelter to recycle aluminum auto parts

- Tita, while providing an elegant answer, forgot to mention that it is mostly cut and paste from Wikipedia. I'll provide the link for her below. She also forgot to copy and paste the part about aluminum oxidizing easily when it is heated and melted. If you are trying to smelter aluminum, you will need to have a compressed or dense mass of aluminum and a smelter that is airtight. Otherwise, it will just oxidize right back into aluminum oxide, which is a white powder. You've probably seen this when you throw a beer can in the campfire? good luck and have fun in your endeavors. And always remember to cite your source!

- Q: What are the physical properties of aluminum?

- Aluminum is a lightweight and malleable metal with a silver-white appearance. It has a relatively low melting point of 660.3 degrees Celsius (1220.5 degrees Fahrenheit) and a boiling point of 2519 degrees Celsius (4566 degrees Fahrenheit). Aluminum has a density of 2.7 grams per cubic centimeter, making it about one-third the density of steel. It is a good conductor of electricity and heat, making it widely used in electrical transmission lines and heat sinks. Aluminum is also resistant to corrosion due to the formation of a thin, protective oxide layer on its surface. This property makes it suitable for various applications in industries such as construction, automotive, aerospace, and packaging.

- Q: How do you protect aluminum sheets from scratches?

- To protect aluminum sheets from scratches, you can apply a protective coating such as a clear lacquer or a durable paint finish. Additionally, using protective films or wraps can also provide a temporary safeguard against scratches during transportation or handling.

- Q: What types of aluminum sheets are recommended for use in cold climates?

- <p>Yes, there are specific types of aluminum sheets suitable for cold climates. These include 3003-H14 and 5052-H32 aluminum sheets. 3003-H14 is known for its excellent corrosion resistance and formability, making it ideal for cold weather applications. 5052-H32 offers high strength and good corrosion resistance, which is beneficial in extreme cold conditions. Both types can withstand low temperatures without significant loss of strength or ductility, ensuring reliability and durability in cold environments.</p>

- Q: Are aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are suitable for marine vessel construction. Aluminum is lightweight, strong, and resistant to corrosion, making it an ideal material for building boats and ships. It also offers good thermal conductivity and is easily weldable, making it a popular choice in the marine industry.

Send your message to us

Mill Finished Aluminum Strips for Cooling - Aluminum Sheets for Sale in NJ

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords