Black Anodized Mill Finished Aluminum Sheet for Building Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finished Aluminium Sheet for Building Ceiling

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finished Aluminium Sheet for Building Ceiling

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finished Aluminium Sheet for Building Ceiling

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

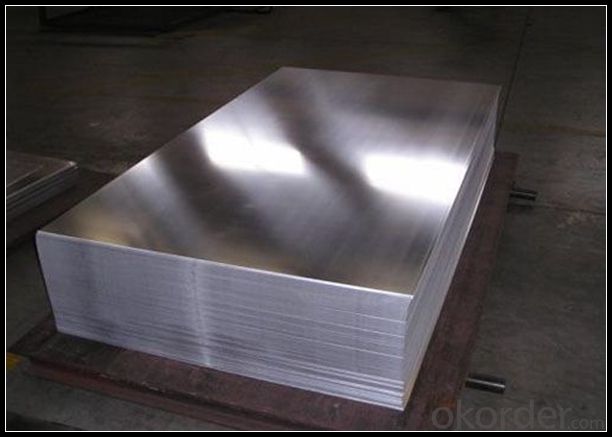

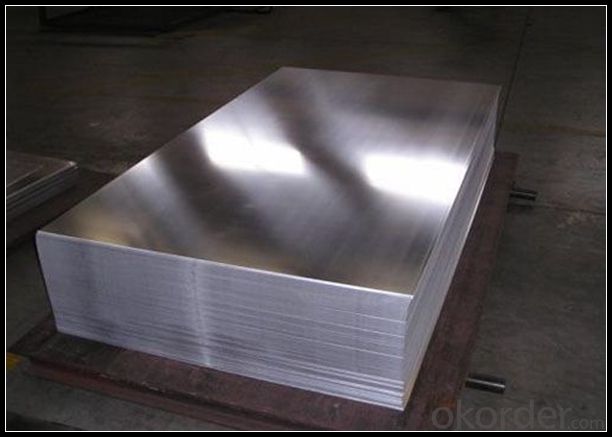

5. Image of Mill Finished Aluminium Sheet for Building Ceiling

6. Package and shipping of Mill Finished Aluminium Sheet for Building Ceiling

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How does the thickness of aluminum sheet affect its formability?

- The thickness of an aluminum sheet has a significant impact on its formability. Generally, thinner sheets of aluminum are more malleable and easier to shape compared to thicker sheets. This is because thinner sheets have lower resistance to deformation and require less force to bend or stretch. Thicker aluminum sheets, on the other hand, have higher resistance to deformation and are less malleable. They require more force and energy to shape, and may be more prone to cracking or tearing during forming processes. Thicker sheets also have a higher likelihood of experiencing springback, where the material partially returns to its original shape after being formed. The formability of aluminum sheets is also influenced by the alloy composition and the specific forming process being used. In some cases, certain alloy compositions or heat treatments can enhance the formability of thicker sheets, making them easier to shape. In summary, the thickness of an aluminum sheet directly affects its formability. Thinner sheets are generally more malleable and easier to shape, while thicker sheets require more force and are less malleable. The alloy composition and specific forming processes being used can also impact the formability of aluminum sheets.

- Q: Can you make tank armor using Aluminium, Polymers, Styrofoam, Explosive Reactive Armor to stop NATO DP rounds and/or HEAT rounds maybe RPG-7?

- Aluminium has a strength up to 800 N/mm2 (for its best Al-based alloys) while steels can go much higher... about 1400 N/mm2 if I recall well. The problem with aluminium is that is prompt to fatigue break which is not good with something vibrating like a rolling tank armor. Polymers are not strong enough unless you use composite materials, for ex. fibre glass or even better - carbon fibre reinforced. The problem is still that unlike steel, the strength is exceptionally high... in one direction - so pray for the impact to be mostly from this direction.

- Q: What is the melting point of aluminum sheets?

- The melting point of aluminum sheets is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: Are 101 aluminum sheets resistant to corrosion?

- Yes, 101 aluminum sheets are resistant to corrosion. Aluminum is naturally resistant to corrosion due to its oxide layer that forms on its surface when exposed to oxygen. This oxide layer acts as a protective barrier against corrosion and prevents the metal from deteriorating. Additionally, the 101 aluminum alloy is specifically designed to have enhanced corrosion resistance properties, making it even more resistant to corrosion compared to other aluminum alloys. Therefore, 101 aluminum sheets are a reliable choice when corrosion resistance is a concern.

- Q: This question asks about the various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with various materials to enhance their properties such as corrosion resistance, appearance, and durability. Some common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the surface. 2. Powder coating, a dry coating that is electrostatically applied and then cured at high temperatures. 3. Paint coating, which can be either liquid or powder-based and provides a decorative and protective layer. 4. Vinyl coating, which is a plastic coating applied for a smooth, matte finish. 5. Electrolytic coating, which involves depositing a thin layer of metal onto the aluminum surface. 6. Hot-dip coating, where aluminum is coated with a layer of zinc or other metals by dipping it into a molten bath. Each type of coating serves different purposes and has unique characteristics.</p>

- Q: Which is good, aluminum curtain wall?

- Aluminum veneer manufacturers preferred Beijing Jinsheng Aluminium Industry Co. Ltd., it is very important to choose a single aluminum plate manufacturers, Beijing Jinsheng Aluminium Industry Co. Ltd is a professional manufacturer of aluminum veneer, advanced CNC equipment, first-class fluorocarbon spraying line, is your trusted manufacturer of aluminum veneer, aluminum veneer of large manufacturers, advanced technology, advanced technology and to undertake all types of single aluminum plate engineering, quality assurance, price concessions.

- Q: I've heard twice in the past 2 days on ESPN that they think Aluminum bats are dangerous. I disagree with this cause if they were dangerous why would they allow them to use them in college and high school. Isnt that what the BESR certification mean that the bat is safe that the ball isnt going to come off at super high speeds. i just wanted to get your opinion.

- in my opinion, when people make an argument about how aluminum bats are dangerous i cant help to imagine a cracked wooden bat flying thru the infield. I think that wooden bats are actually more dangerous. a lot of people that don't like aluminum bats say that one day a fly ball is gonna kill someone off of a aluminum bat, but the same thing would probably happen woth a wooden bat. i personally love to use aluminum bats and a hate it when my high school coach makes me use a wooden bat.

- Q: Are aluminum sheets suitable for lighting fixtures?

- Yes, aluminum sheets are suitable for lighting fixtures. Aluminum is a versatile and durable material that is commonly used in the manufacturing of lighting fixtures. It offers several advantages that make it a popular choice for this purpose. Firstly, aluminum is lightweight, which makes it easier to handle and install lighting fixtures. It is also highly corrosion-resistant, ensuring that the fixtures can withstand various environmental conditions without deteriorating or rusting over time. Additionally, aluminum has excellent thermal conductivity, allowing it to efficiently dissipate heat generated by the lighting fixtures, which helps in preventing overheating and prolonging their lifespan. Moreover, aluminum can be easily shaped and formed into various designs, making it ideal for creating aesthetically pleasing lighting fixtures. It can be extruded, rolled, or stamped to achieve different shapes and sizes, allowing for a wide range of creative possibilities. Furthermore, aluminum is a cost-effective material compared to other metals commonly used in lighting fixtures, such as brass or copper. It is readily available and has a lower price point, making it a more affordable option for both manufacturers and consumers. In summary, aluminum sheets are indeed suitable for lighting fixtures due to their lightweight nature, corrosion resistance, excellent thermal conductivity, versatility in design, and cost-effectiveness.

- Q: Can 101 aluminum sheets be anodized for outdoor architectural applications?

- Yes, 101 aluminum sheets can be anodized for outdoor architectural applications.

- Q: Can aluminum sheets be used for food display cases?

- Yes, aluminum sheets can be used for food display cases. Aluminum is a common material used in the food industry due to its durability, light weight, and resistance to corrosion. It is also easy to clean and maintain, making it suitable for displaying food in a hygienic and visually appealing way.

Send your message to us

Black Anodized Mill Finished Aluminum Sheet for Building Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords