Custom Rolled Aluminum Coil - Mill Finish Aluminum Coil 3003 H14 for Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminium Coil 3003 H14 for Color Coating

Material | Alloy Aluminum 1XXX,3XXX,5XXX or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating,PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Mill Finish Aluminium Coil 3003 H14 for Color Coating

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Coil 3003 H14 for Color Coating

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

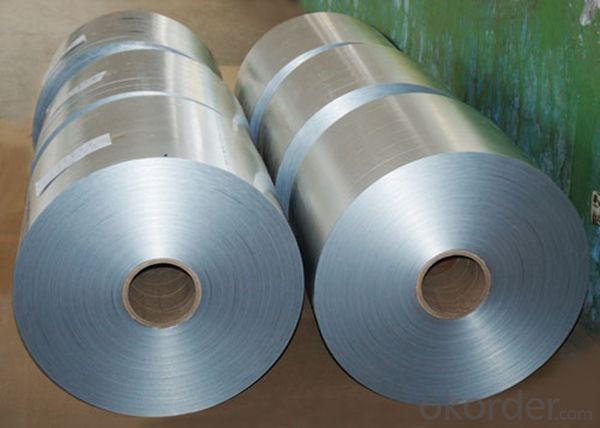

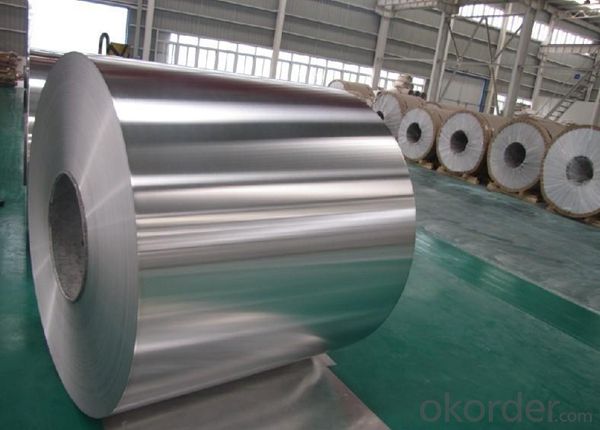

5. Image of Mill Finish Aluminium Coil 3003 H14 for Color Coating

6. Package and shipping of Mill Finish Aluminium Coil 3003 H14 for Color Coating

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum coils suitable for chemical processing applications?

- Yes, aluminum coils are suitable for chemical processing applications. Aluminum is known for its excellent corrosion resistance and high thermal conductivity, making it an ideal choice for various chemical processes. It can withstand different chemicals and acids, and its lightweight nature allows for easy handling and installation. Additionally, aluminum coils provide good heat transfer and can be easily formed into various shapes, making them versatile for different chemical processing requirements.

- Q: i need ONE advantage of each, and a final reason why aluminium is used?

- Copper and Aluminum are both great conductors of electricity. Aluminum is actually more dangerous than copper, as it expands/contracts a lot more with heat, and is a primary cause of house fires. Copper's advantage is that it is more reliable, it doesn't corrode as easily, and does not expand/contract much with application of heat. I believe that aluminum has an edge as a conductor, though, and is less expensive to manufacture.

- Q: Can aluminum coils be used in solar panel manufacturing?

- Solar panel manufacturing can incorporate aluminum coils as they are lightweight and durable. This material is widely utilized across industries, including the solar panel manufacturing sector, due to its exceptional thermal conductivity, resistance to corrosion, and cost-effectiveness. In the production of solar panels, aluminum coils are commonly employed to construct the frame or support structure for the photovoltaic cells. By fabricating and shaping the coils to the desired configuration, a robust and steady structure is achieved for the solar panel. Furthermore, aluminum is recyclable, making it an environmentally conscious option for the production of solar panels.

- Q: Are aluminum coils suitable for solar panel frames?

- Yes, aluminum coils are suitable for solar panel frames. Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity, making it an ideal material for solar panel frames. It offers durability, easy installation, and efficient heat dissipation, ensuring the longevity and optimal performance of solar panels.

- Q: What is the corrosion resistance of aluminum coils?

- Aluminum coils exhibit excellent corrosion resistance due to the formation of a protective oxide layer on its surface. This oxide layer acts as a barrier, preventing further corrosion and providing long-term durability. The corrosion resistance of aluminum coils is further enhanced through various surface treatments and coatings, such as anodizing or painting, which provide an additional layer of protection. This makes aluminum coils a reliable choice for a wide range of applications in industries such as construction, automotive, and aerospace, where resistance to corrosion is essential.

- Q: Can aluminum coils be used in solar panel applications?

- Yes, aluminum coils can be used in solar panel applications. Aluminum is a lightweight, durable, and corrosion-resistant material that is commonly used in the construction of solar panels. It is often used as a component in the frame or as a backsheet material, providing structural support and protection to the solar cells.

- Q: Domestic production of color coated aluminum coil manufacturers which good?

- It is widely used in the field of architectural decoration, such as aluminum ceiling, aluminum plate and so on. There are many manufacturers of color coated aluminum rolls, big and small.

- Q: How are aluminum coils used in the production of food processing equipment?

- Aluminum coils are commonly used in the production of food processing equipment due to their excellent thermal conductivity, corrosion resistance, and lightweight nature. These coils are often formed into various shapes and sizes to create components like heat exchangers, evaporators, and condensers that help regulate temperature during food processing. Additionally, aluminum coils can be easily cleaned and sanitized, making them ideal for use in the food industry where hygiene is crucial.

- Q: Are there any limitations to the maximum coil length of aluminum coils?

- Yes, there are limitations to the maximum coil length of aluminum coils. The maximum coil length depends on various factors such as the thickness and width of the aluminum coil, the strength and tensile properties of the aluminum alloy, the equipment used for coil processing, and the intended application of the coil. One limitation is the strength and ductility of the aluminum alloy being used. Aluminum alloys with higher strength and lower ductility may have limitations on the maximum coil length due to the risk of coil breakage or deformation during processing or handling. Another limitation is the equipment used for coil processing. The maximum coil length is often determined by the size and capabilities of the equipment used for slitting, cutting, or forming the coils. If the equipment has a limited capacity or is not designed for longer coils, it may not be able to handle or process longer lengths effectively. The intended application of the coil can also impose limitations on the maximum coil length. For example, if the coil is intended for transportation purposes, such as in the automotive industry, there may be restrictions on the maximum coil length based on the size and weight limitations of the vehicles. Additionally, logistical factors such as transportation and storage can also impose limitations on the maximum coil length. Longer coils may be more difficult to handle, transport, and store, which can increase the risk of damage or pose challenges in terms of logistics and space requirements. Therefore, while there is no specific universal limit to the maximum coil length of aluminum coils, it is essential to consider various factors such as alloy properties, equipment capabilities, application requirements, and logistical considerations to determine the practical limitations of coil length for a specific situation.

- Q: I have completely disassembled my aluminum bass boat and it is being sandblasted.I am restoring the boat and will be giving it a new paint job.What do you recommend in the way of primer,paint or anything else I need to know.I just don,t want to mess it up by using the wrong thing.Best answer gets a fishing trip in the same boat we are talking about. If you can make it here I will put you on some fish.Catfish,bream,crappie,bass or even saltwater fish.

- Altough Pettit says you can topcoat this primer, you will probably get a better result if you prime the primer with whatever is recommended for the type of topcoat you use. For the hull, use a paint with a high UV rating, and avoid using red, it oxidizes faster. I would also suggest you use the Alumaprotect inside the hull as well.

Send your message to us

Custom Rolled Aluminum Coil - Mill Finish Aluminum Coil 3003 H14 for Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords