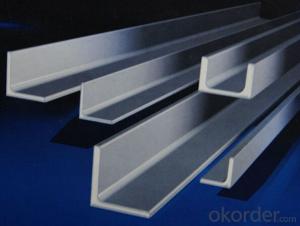

Mild Steel Prime Hot Rolled Angle Bar Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Mild Steel Prime Hot Rolled Angle Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Mild Steel Prime Hot Rolled Angle Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Mild Steel Prime Hot Rolled Angle Steel are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

EQUAL ANGLES SIZES | |||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How many tons of steel products could be loaded in containers?

A3: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Q4: what is the difference between actual weight and theoretical weight?

A4: All the section steel has two weights: actual weight and theoretical weight. Actual weight is the weighing out when the product delivered from the mill. Theoretical weight is calculated by pieces. The invoice can be based on each of them as your request.

Images:

- Q: Where can you buy steel angles?

- There are various places where you can purchase steel angles. One possibility is to pay a visit to a local hardware or building supply store. These establishments usually have a wide selection of construction materials, which includes steel angles, that you can buy. Moreover, you can also inquire with metal suppliers or steel fabricators in your vicinity. They typically specialize in the sale of steel products, including angles, and can offer you a variety of choices to select from. Another option is to explore online marketplaces and industrial supply websites. These platforms present a convenient means to browse and purchase steel angles from a range of suppliers, often with the added benefit of being able to compare prices and read customer reviews. Whether you have a preference for shopping in person or online, there are numerous options available to fulfill your specific requirements for purchasing steel angles.

- Q: Are steel angles available in different alloys?

- Yes, steel angles are available in different alloys. Steel angles are typically made from carbon steel, which is the most common and versatile type of steel. However, there are also other alloys available for specific applications. For example, stainless steel angles are made from an alloy that contains chromium, which provides increased resistance to corrosion. Additionally, there are high-strength low-alloy (HSLA) steel angles that are made with a combination of carbon steel and small amounts of other elements like manganese, phosphorus, or sulfur to enhance their strength and durability. Overall, the availability of different alloys for steel angles allows for a wide range of applications and properties to meet specific needs in various industries.

- Q: What are the different types of steel angles used in construction?

- There are several different types of steel angles commonly used in construction. These angles are formed by bending a piece of steel into a 90-degree angle, creating an L-shape. The different types of steel angles used in construction include: 1. Equal angles: These angles have equal lengths on both sides, forming a right angle. They are commonly used for making frames, supports, or braces in construction projects. 2. Unequal angles: As the name suggests, unequal angles have different lengths on each side. They are often used in applications where one side needs to be longer or shorter than the other. Unequal angles are commonly used for structural support in buildings, bridges, and other infrastructure projects. 3. L-shaped angles: These angles have a 90-degree bend but do not have equal lengths on both sides. They are often used in situations where a specific length is required on one side, such as creating a shelf or bracket. 4. Rolled steel angles: These angles are produced by passing a steel strip through a series of rollers, which shape it into the desired angle. Rolled steel angles are commonly used in construction projects for their strength and durability. 5. Stainless steel angles: Stainless steel angles are made from a corrosion-resistant alloy, making them ideal for applications where they may be exposed to moisture or harsh environments. They are commonly used in construction projects where aesthetics and longevity are important, such as architectural structures or exterior cladding. 6. Galvanized steel angles: Galvanized steel angles are coated with a layer of zinc to protect them from corrosion. This makes them suitable for outdoor applications, where they may be exposed to moisture or harsh weather conditions. Galvanized steel angles are commonly used in construction projects, such as fences, handrails, or outdoor structures. In summary, the different types of steel angles used in construction include equal angles, unequal angles, L-shaped angles, rolled steel angles, stainless steel angles, and galvanized steel angles. Each type has its own unique properties and applications, making them versatile and essential components in various construction projects.

- Q: Are steel angles suitable for high-temperature environments?

- No, steel angles are not suitable for high-temperature environments as they tend to lose their structural integrity and strength at elevated temperatures.

- Q: Can steel angles be used in railway or transportation infrastructure?

- Steel angles have the potential to be utilized in railway or transportation infrastructure. They are frequently employed in the building of bridges, tunnels, and railway tracks. These infrastructure components rely on steel angles for structural support and stability. The reputation of steel angles stems from their strength, durability, and versatility. They can be effortlessly fabricated and installed, which contributes to their popularity in transportation projects. Additionally, steel angles possess the ability to endure substantial loads and adverse weather conditions, rendering them suitable for railway and transportation purposes where safety and reliability are of utmost importance. In summary, steel angles offer a dependable and cost-effective solution for railway and transportation infrastructure needs.

- Q: How do steel angles contribute to energy-efficient construction?

- Steel angles contribute to energy-efficient construction in several ways. Firstly, steel angles are commonly used as structural components in buildings, such as in the framing of walls, roofs, and floors. Their high strength-to-weight ratio allows for the creation of lighter and more efficient structures. This means that less steel is needed to support the building, reducing the overall weight and material usage, which in turn reduces the energy required for construction and transportation. Secondly, steel angles can be easily prefabricated off-site, allowing for faster construction times and reduced labor costs. This not only saves time and money but also minimizes energy consumption during the construction process. Moreover, steel is a highly durable and long-lasting material, which reduces the need for frequent maintenance and repairs. This durability translates into energy savings over the life cycle of the building, as less energy is required for ongoing maintenance and replacements. Additionally, steel angles can be recycled at the end of their life cycle, reducing the demand for virgin materials and minimizing the environmental impact of construction. The recycling process requires less energy compared to the production of new steel, resulting in energy savings and reduced greenhouse gas emissions. Lastly, steel angles can be integrated into energy-efficient building systems, such as insulation, HVAC ductwork, and renewable energy installations. The versatility of steel allows for the creation of systems that optimize energy performance, such as efficient heating and cooling systems or solar panel installations. In conclusion, steel angles contribute to energy-efficient construction by providing strength and stability while reducing material usage, enabling faster construction times, minimizing maintenance needs, facilitating recycling, and integrating with energy-efficient building systems.

- Q: Can steel angles be used as bracing elements?

- Yes, steel angles can be used as bracing elements. Steel angles are often used in construction as bracing elements due to their strength and stability. They can effectively provide support and enhance the structural integrity of a building or structure.

- Q: How do you calculate the moment capacity of a steel angle?

- To calculate the moment capacity of a steel angle, you need to consider the properties of the angle section and the applied load. The moment capacity is determined by calculating the plastic section modulus of the angle and multiplying it by the yield strength of the steel material. This calculation helps determine the maximum moment the angle can resist before it reaches its yield point.

- Q: What is the cost of steel angles compared to other materials?

- The cost of steel angles compared to other materials can vary depending on various factors such as the type and grade of steel, market conditions, and availability. However, in general, steel angles tend to be a cost-effective option when compared to other materials commonly used for structural or construction purposes. Steel angles are widely used in various industries including construction, manufacturing, and infrastructure due to their durability, strength, and versatility. Compared to materials like aluminum or stainless steel, steel angles are often more affordable. This is because steel is a widely available material and can be produced in large quantities, leading to cost efficiencies in manufacturing processes. Additionally, steel angles have a long lifespan and require minimal maintenance, further contributing to their cost-effectiveness over time. They also offer excellent load-bearing capabilities, making them suitable for a wide range of applications, including building frames, support structures, and machinery. However, it is important to note that the cost of steel angles can still vary depending on the specific requirements and specifications of a project. Factors such as size, length, thickness, and any additional treatments or finishes can influence the price. Therefore, it is advisable to consult with suppliers or manufacturers to obtain accurate and up-to-date pricing information based on individual project needs.

- Q: Can steel angles be used in mezzanine flooring systems?

- Yes, steel angles can be used in mezzanine flooring systems. Steel angles are commonly used as structural components in mezzanine floors due to their strength and versatility. They provide crucial support for the elevated floor structure, ensuring stability and load-bearing capacity. Additionally, steel angles can be easily connected and integrated into the overall mezzanine design, making them a popular choice in mezzanine flooring systems.

Send your message to us

Mild Steel Prime Hot Rolled Angle Bar Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords