Mild Steel HRB 400 Steel Rebar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 130 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

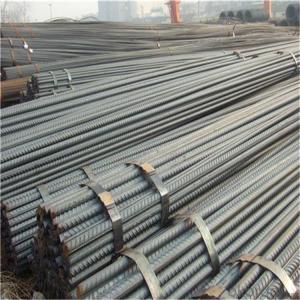

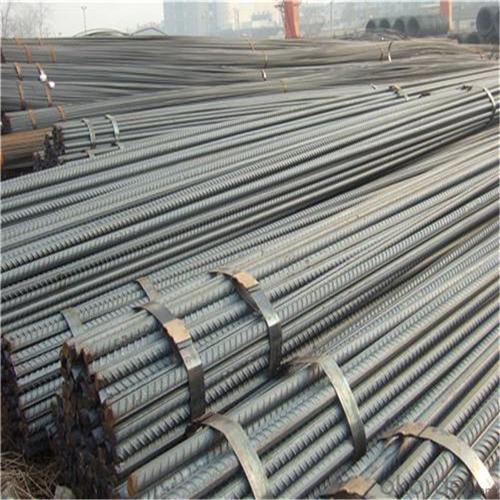

Mild Steel HRB 400 Steel Rebar

Description of Mild Steel HRB 400 Steel Rebar

1, Diameter: 5.5mm-10mm Mild Steel HRB 400 Steel Rebar

10m- 40mm Mild Steel HRB 400 Steel Rebar

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Mild Steel HRB 400 Steel Rebar

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

Products Show of Mild Steel HRB 400 Steel Rebar

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How does special steel contribute to improving product safety in high-risk industries?

- Special steel plays a crucial role in enhancing product safety in high-risk industries due to its unique properties. Its exceptional strength, durability, and resistance to corrosion and wear make it ideal for manufacturing critical components in sectors like aerospace, automotive, and energy. By using special steel, manufacturers can ensure that their products can withstand extreme conditions, reducing the risk of failure or malfunction. This, in turn, enhances the safety of the end-users and prevents potential accidents or disasters in high-risk industries.

- Q: What are the specific requirements for special steel used in the mining industry?

- Special steel used in the mining industry has specific requirements to ensure its durability, strength, and resistance to harsh conditions. Some of the key requirements for special steel used in the mining industry include: 1. High strength: Special steel used in the mining industry must have high tensile strength to withstand heavy loads and resist deformation under extreme conditions. This enables the steel to endure the pressure, impact, and stress that it may encounter during mining operations. 2. Wear resistance: Mining environments involve abrasive materials, such as rocks and ores, which can cause significant wear on equipment. Special steel used in the mining industry needs to have excellent wear resistance to prevent premature failure and increase the lifespan of mining equipment. 3. Corrosion resistance: Mining operations often take place in highly corrosive environments, such as underground mines or near water bodies. Special steel used in the mining industry should possess high corrosion resistance to withstand exposure to chemicals, moisture, and other corrosive agents. This helps prevent rusting, pitting, and other forms of corrosion that can weaken the steel. 4. Toughness: Mining equipment is subjected to heavy impacts and vibrations, which can lead to fractures if the steel is not tough enough. Special steel used in the mining industry should exhibit excellent toughness, allowing it to absorb energy from impacts and vibrations without fracturing. This ensures the safety and reliability of mining equipment. 5. Heat resistance: Mining operations involve high-temperature environments, such as smelting and refining processes. Special steel used in the mining industry must have good heat resistance to withstand the elevated temperatures without losing its strength or undergoing deformation. 6. Machinability: Special steel used in the mining industry should also have good machinability, allowing it to be easily formed into complex shapes or structures. This facilitates the manufacturing process of mining equipment and components. Overall, the specific requirements for special steel used in the mining industry revolve around strength, wear resistance, corrosion resistance, toughness, heat resistance, and machinability. Meeting these requirements is crucial for ensuring the reliability, durability, and safety of mining equipment in the demanding mining environments.

- Q: How does special steel contribute to the automotive exhaust system industry?

- The automotive exhaust system industry greatly benefits from the use of special steel, which makes significant contributions. Firstly, special steel, such as stainless steel, offers excellent resistance to corrosion, a common problem faced by exhaust systems due to exposure to high temperatures and corrosive gases. This corrosion resistance ensures the longevity and durability of the exhaust system, reducing the need for frequent replacements and repairs. Additionally, special steel possesses outstanding heat resistance properties. As the exhaust system operates under extreme temperatures, special steel can withstand these conditions without deforming or suffering structural damage. This ability to handle high temperatures ensures the efficient functioning and long-term performance of the exhaust system. Moreover, special steel provides exceptional strength and durability. The exhaust system is constantly subjected to vibrations, impacts, and stress due to road conditions and engine movements. The high strength and toughness of special steel enable the exhaust system to withstand these forces, preventing premature failures and ensuring the safety and reliability of the vehicle. Furthermore, special steel allows for the design and production of intricate and lightweight components for the exhaust system. With advancements in steel technology, manufacturers can create complex shapes and thin-walled structures, reducing the overall weight of the exhaust system. This weight reduction contributes to improved fuel efficiency and vehicle performance by reducing the burden on the engine. Lastly, special steel offers the automotive industry the flexibility to meet increasingly strict emission regulations. By incorporating special steel in the exhaust system, manufacturers can effectively integrate catalytic converters and other emission control devices. These devices play a crucial role in reducing harmful emissions like carbon monoxide, nitrogen oxides, and particulate matter, thus ensuring compliance with environmental standards. In conclusion, special steel is an indispensable element in the automotive exhaust system industry. Its corrosion resistance, heat resistance, strength, and lightweight properties contribute to the longevity, reliability, and performance of the exhaust system. Additionally, special steel enables compliance with emission regulations, making vehicles more environmentally friendly. Ultimately, special steel plays a vital role in improving the efficiency and sustainability of the automotive exhaust system industry.

- Q: What are the different surface treatment methods for special steel?

- Some of the different surface treatment methods for special steel include heat treatment, coating or plating, polishing, shot blasting, and passivation. Heat treatment involves subjecting the steel to specific temperatures and cooling processes to alter its properties. Coating or plating involves applying a layer of another material, such as zinc or chrome, to protect the steel from corrosion. Polishing is done to create a smooth and glossy surface finish. Shot blasting is a process that involves using abrasive materials to remove impurities and create a textured surface. Passivation is a chemical treatment used to remove iron contaminants and improve corrosion resistance. These methods can be utilized individually or in combination to enhance the surface characteristics of special steel.

- Q: What are the different types of heat treatment processes used for special steel?

- The different types of heat treatment processes used for special steel include annealing, normalizing, hardening, tempering, and quenching.

- Q: How does special steel contribute to the transportation sector?

- Special steel contributes to the transportation sector by providing high-strength and lightweight materials that enhance the performance, efficiency, and safety of vehicles. It is used in various components, such as engine parts, chassis, and suspension systems, to improve fuel economy, reduce emissions, and enhance durability. Additionally, special steel's corrosion resistance properties make it suitable for manufacturing components in harsh environments, such as marine and aerospace applications, further expanding its contribution to the transportation industry.

- Q: What are the specific requirements for special steel used in the marine propeller industry?

- The special steel used in the marine propeller industry must meet specific requirements to ensure optimal performance and durability in harsh marine environments. Some of the key requirements include: 1. Corrosion Resistance: Marine propellers are constantly exposed to saltwater, which can cause corrosion. Therefore, special steel used in the marine propeller industry must have high resistance to corrosion, preventing the formation of rust and maintaining the propeller's integrity over time. 2. Strength and Toughness: Marine propellers are subjected to high mechanical stresses and impacts, especially in rough sea conditions. The special steel used must possess high strength and toughness to withstand these forces without deformation or failure. 3. Fatigue Resistance: Propellers experience cyclic loading due to rotational forces, which can lead to fatigue failure over time. The special steel should have excellent fatigue resistance to withstand millions of load cycles without developing cracks or fractures. 4. Weldability: Propellers are often manufactured in segments and then welded together. The special steel used must be easily weldable, ensuring strong and reliable joints that can withstand the propeller's operational stresses. 5. Heat Resistance: Propellers generate significant heat due to friction and propulsion forces. The special steel should have good heat resistance to prevent deformation or loss of mechanical properties at elevated temperatures. 6. Machinability: Special steel used in the marine propeller industry should be readily machinable to allow for precise shaping and finishing of complex propeller blade designs. 7. Non-Magnetic Properties: Many modern ships utilize magnetic navigation systems and sensors. Therefore, the special steel used in propellers should have low magnetic permeability to minimize interference with these systems. Meeting these specific requirements ensures that the special steel used in the marine propeller industry can withstand the challenging conditions of seawater, provide efficient propulsion, and maintain its structural integrity throughout the propeller's lifespan.

- Q: How does special steel compare to other materials?

- Special steel, known as alloy steel as well, possesses outstanding strength, durability, and resistance to wear and corrosion. When compared to regular steel, aluminum, and plastic, special steel stands out due to its superior mechanical properties. To begin with, special steel offers higher tensile strength and hardness, making it perfect for applications that require heavy-duty performance. Its ability to withstand high pressures and temperatures, as well as resistance to deformation, make it suitable for industries like aerospace, automotive, and construction. Furthermore, special steel has excellent wear resistance, making it suitable for applications that endure friction, abrasion, and impact. This characteristic reduces the need for frequent repairs or replacements, resulting in cost savings and improved efficiency. When it comes to corrosion resistance, special steel surpasses regular steel, which tends to rust when exposed to moisture or aggressive environments. The presence of elements like chromium, nickel, and molybdenum in its composition creates a protective layer on the surface, preventing corrosion and extending the lifespan of the material. Compared to materials like aluminum and plastic, special steel has the advantage of being more robust and less prone to deformation or breakage. While aluminum is lightweight, it lacks the strength and hardness of special steel, limiting its suitability for heavy-duty applications. On the other hand, plastic offers lower strength and durability compared to special steel, making it less appropriate for demanding tasks. Moreover, special steel can be easily machined, fabricated, and welded, allowing for versatile applications across various industries. Its flexibility in terms of shaping and forming makes it the preferred choice in the manufacturing of components and structures. In conclusion, special steel outperforms other materials in terms of strength, durability, wear resistance, corrosion resistance, and versatility. Its exceptional properties make it an essential material in demanding industries where reliability and performance are of utmost importance.

- Q: Can special steel be used for automotive engine components?

- Yes, special steel can be used for automotive engine components. Special steel, such as high-strength alloys or stainless steel, can offer superior mechanical properties, corrosion resistance, and heat resistance, making it suitable for demanding engine applications.

- Q: How is special steel used in the production of cutting inserts?

- Special steel is used in the production of cutting inserts due to its unique properties, such as high hardness, wear resistance, and heat resistance. These qualities make it effective for withstanding the high temperatures and forces involved in cutting operations. Special steel cutting inserts are designed to cut through various materials, including metals, plastics, and composites, with precision and efficiency, making them essential tools in industries such as manufacturing, automotive, and aerospace.

Send your message to us

Mild Steel HRB 400 Steel Rebar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 130 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords