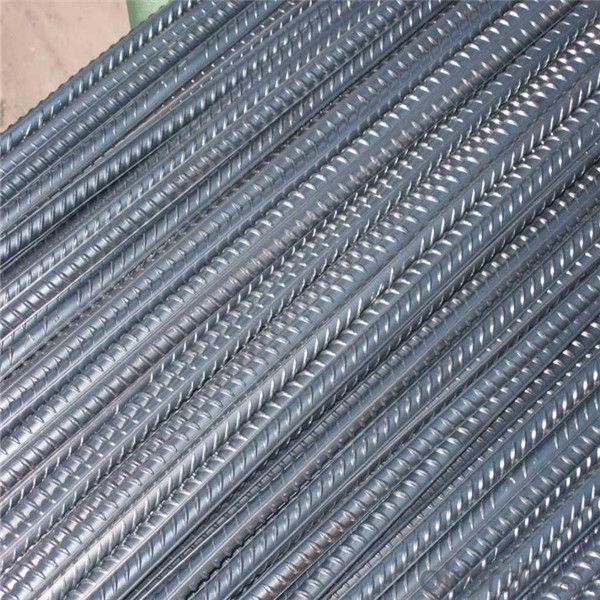

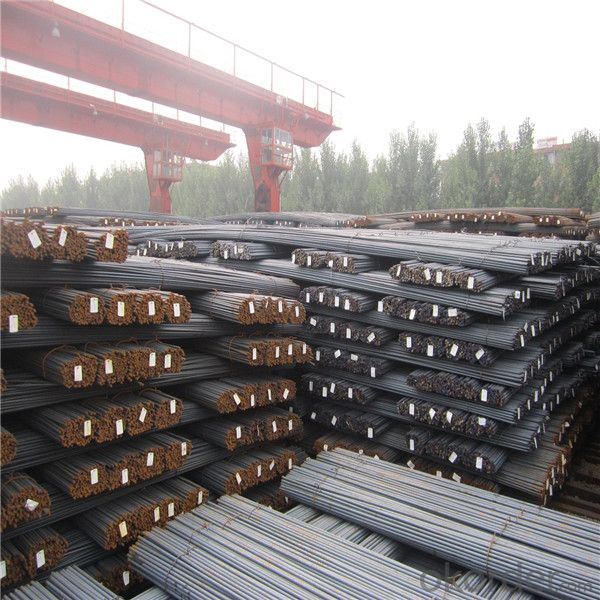

HRB400 HRB 500 steel rebar Good quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19863 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Deformed Steel bar is a common steel reinforcing bar, used in reinforced concrete and reinforced masonry structures.

It is formed from mild steel, and is given ribs for better frictional adhesion to the concrete. The Deformed Steel bar is

an iron rod , a weldable plain reinforcing steel bar, and can be used as well for steel meshes.

Our Advantage:

High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: How do steel rebars improve the strength and durability of concrete?

- The strength and durability of concrete are greatly improved by steel rebars in several ways. Firstly, the inclusion of rebars reinforces the concrete structure, significantly increasing its tensile strength. While concrete is adept at resisting compression forces, it is weaker in tension. By embedding steel rebars within the concrete, the structure's ability to resist bending, cracking, and collapsing under heavy loads or external forces is greatly enhanced. Secondly, the presence of steel rebars prevents the occurrence of cracking and shrinkage in the concrete. As concrete dries and cures, it tends to shrink, leading to the formation of cracks. However, rebars help control and restrict this shrinkage by providing additional support and structural integrity. This effectively reduces the occurrence of cracks and ensures the long-term strength and durability of the concrete. Furthermore, the overall structural stability of the concrete is improved by steel rebars. When subjected to dynamic loads or seismic activity, concrete can undergo significant deformation or even fail. The inclusion of rebars helps distribute the load more evenly throughout the concrete structure, minimizing the risk of localized damage or collapse. This ultimately enhances the stability and safety of the concrete construction. Lastly, steel rebars contribute to the longevity and durability of concrete structures. The steel used in rebars is highly resistant to corrosion, which is a common issue in concrete exposed to harsh environmental conditions or moisture. By providing a protective layer called passivation, rebars prevent corrosion and maintain the structural integrity of the concrete over an extended period. This ensures that the concrete remains strong, durable, and resistant to degradation throughout its lifespan. In conclusion, steel rebars play a critical role in enhancing the strength and durability of concrete. They improve tensile strength, prevent cracking and shrinkage, enhance structural stability, and increase the lifespan of concrete structures. With the inclusion of steel rebars, concrete becomes a dependable and long-lasting construction material capable of withstanding various loads and environmental conditions.

- Q: What are the common problems associated with steel rebars in construction?

- Steel rebars in construction can pose several common problems. One of the primary concerns is corrosion, as moisture and oxygen can cause rusting, particularly in humid or coastal areas. This rusting weakens the rebars and compromises the structure's integrity. Improper installation is another issue. If rebars are not correctly positioned or adequately secured, they fail to provide the necessary reinforcement and support, leading to safety hazards and structural failures. Concerns also arise regarding the size and spacing of rebars. Inadequate distribution of loads or poor resistance to bending and cracking can occur if the rebars are too small or spaced too far apart. Conversely, if the rebars are too large or closely placed, construction costs increase, and the concrete mix becomes difficult to work with. Poor bonding between the rebar and the concrete poses another challenge. Inadequate contact or bonding between these materials compromises the structure's integrity and reduces the load-bearing capacity of the reinforced concrete. Lastly, the quality of the steel rebars themselves can be problematic. Defects such as impurities or inconsistencies in composition weaken the reinforcement and compromise the overall strength of the structure. To address these issues, it is crucial to use high-quality rebars, adhere to proper installation techniques, and ensure maintenance and protection against corrosion. Regular inspections and testing aid in identifying problems and ensuring the longevity and safety of the reinforced concrete structure.

- Q: Can steel rebars be used in the construction of power plants or industrial facilities?

- Yes, steel rebars can be used in the construction of power plants or industrial facilities. Steel rebars are extremely strong and durable, making them an ideal choice for reinforcing concrete structures in these types of facilities. They provide the necessary strength and support to withstand heavy loads, vibrations, and extreme temperatures that are often encountered in power plants and industrial facilities. Additionally, steel rebars are resistant to corrosion, which is crucial in these environments where exposure to moisture, chemicals, and other harsh elements is common. Therefore, steel rebars are commonly used in the construction of power plants and industrial facilities to ensure the structural integrity and longevity of the buildings.

- Q: What is the role of steel rebars in preventing structural collapse?

- The prevention of structural collapse is a crucial role played by steel rebars, as they reinforce concrete structures. While concrete is strong in compression, it lacks strength in tension. This is where steel rebars come into play, effectively enhancing the tensile strength of the concrete. When a building or any concrete structure is subjected to structural loads, the rebars distribute the load across a wider area. This prevents the concrete from cracking and failing under stress. By providing a means for the concrete to resist tension and bending forces, steel rebars help maintain the integrity and stability of the structure. In addition to improving tensile strength, rebars also increase the overall ductility and flexibility of the concrete. This is especially important during events like earthquakes or high winds, as structures must withstand significant lateral forces. The presence of rebars allows the concrete to absorb and dissipate these forces, reducing the risk of structural failure. Furthermore, steel rebars play a role in preventing structural collapse by resisting the effects of corrosion. When embedded in concrete, the rebars are shielded from moisture and other corrosive elements. This ensures their long-term durability and ability to support the structure. To summarize, steel rebars are essential components in preventing structural collapse. They reinforce concrete structures, enhance tensile strength, improve ductility, resist corrosion, and ultimately contribute to the overall safety and stability of buildings and other concrete constructions.

- Q: What is the role of steel rebars in reducing concrete shrinkage?

- Steel rebars play a crucial role in reducing concrete shrinkage by providing reinforcement and added strength to the concrete structure. When concrete cures, it undergoes a process called hydration, where it loses water and shrinks in volume. This shrinkage can lead to cracking and overall structural instability. By placing steel rebars within the concrete, they act as a reinforcement and help to counteract the forces of shrinkage. The rebars provide tensile strength, which is the ability to resist pulling or stretching forces. As the concrete shrinks, the rebars hold it together and prevent excessive cracking. Additionally, the steel rebars help to distribute the load more evenly throughout the concrete structure. This reduces the concentration of stress in specific areas, further minimizing the potential for shrinkage-related cracking. Furthermore, steel rebars can also act as a thermal conductor, allowing heat to dissipate more evenly throughout the concrete. This helps to prevent temperature differentials within the structure, which can lead to differential shrinkage and subsequent cracking. In summary, the role of steel rebars in reducing concrete shrinkage is to provide reinforcement, resist tensile forces, distribute loads, and regulate temperature differentials. By doing so, they enhance the overall durability and stability of the concrete structure, minimizing the negative effects of shrinkage.

- Q: What is hot rolled coil? Hot rolled coil relative to thread steel and other steel, is not considered a higher point?

- Cold rolled strip is produced by pickling, rolling, annealing, finishing and oiling.Which requirements are higher for strip and thread steel, and because of the different products, the individual considers that there is no comparability.

- Q: What is the process of testing the quality of steel rebars?

- To ensure compliance with industry standards and specifications, the quality of steel rebars undergoes a series of steps in the testing process. Firstly, visual inspection is conducted to identify any visible defects, such as cracks, irregularities, or improper dimensions. Next, a sample of the rebars is taken for chemical composition analysis. This analysis determines the composition of the steel, including carbon, manganese, sulfur, phosphorus, and other elements, ensuring it meets the required standards for strength and durability. To measure the maximum stress the rebars can endure without deformation or failure, a tensile strength test is performed. This involves applying an increasing load to a sample until it breaks, with the tensile strength calculated by dividing the breaking load by the sample's cross-sectional area. The bend test evaluates the rebar's ductility by bending a sample to a specified angle without any cracks or fractures occurring. This test assesses the rebars' ability to withstand bending and shaping during construction. For rebars intended for use in welded structures, a weldability test is conducted to ensure there are no issues, such as cracking or loss of strength, during the welding process. The rebars are also inspected for dimensional and weight compliance, including length, diameter, and weight. Any deviations from the required specifications may indicate potential quality issues. To assess the rebars' resistance to corrosion over time, a corrosion resistance test is carried out. This involves subjecting the rebars to a corrosive environment or using accelerated corrosion testing methods. Non-destructive testing techniques, such as ultrasonic testing, magnetic particle inspection, or radiographic testing, may be employed to detect any internal defects or irregularities that are not visible to the naked eye. These tests ensure the integrity and quality of the rebars. Once all the tests are completed and the rebars meet the required standards, they are certified and documented. This documentation serves as evidence of the rebars' quality and compliance, ensuring safety and durability in construction projects. By following these comprehensive testing procedures, builders, engineers, and end-users can be assured that the steel rebars meet the necessary quality standards for their intended applications.

- Q: Are steel rebars suitable for use in industrial facilities?

- Yes, steel rebars are suitable for use in industrial facilities. They provide excellent strength and durability, making them ideal for reinforcing concrete structures in such facilities. Steel rebars can withstand heavy loads and extreme conditions, ensuring the safety and long-term stability of industrial buildings and infrastructure.

- Q: How do steel rebars perform in seismic zones?

- Steel rebars perform well in seismic zones due to their high tensile strength and ductility. They can withstand the intense forces and vibrations generated during earthquakes, effectively reinforcing and strengthening concrete structures. The use of rebars helps prevent structural failure and ensures the safety and stability of buildings in seismic-prone areas.

Send your message to us

HRB400 HRB 500 steel rebar Good quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19863 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords