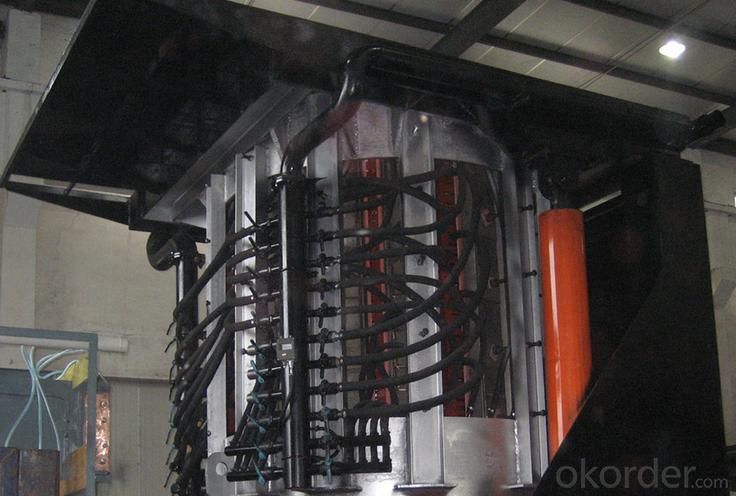

Middle frequency induction furnace with parralel or series connection

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Plywood case |

| Delivery Detail: | 45DAYS |

Specifications

5ton 3000kw middle frequency induction furnace with parralel or series connection technology with 520-550KWH/T.

5ton melting furnace

Main specification:5ton 3000kw middle frequency induction smelting furnace with parralel or series connection technology with 520-550KWH/T.

he main equipment of this program is included one rectification transformer of 4000KVA, 2 frequency power (rectifier and inverter system), 1 set capacitor cabinet, power 4000KVA , frequency of 500HZ, two induction furnace for 5T, 1 hydraulic station, 1 cooling water device, and other auxiliary device.

Following is parrallel connection ,pls send enquiry if you want series.

Name | Unit | Parameter | Remark | |

Rated capacity | t | 5 |

| |

Max load capacity | t | 7 |

| |

Rated power | KW | 3000 |

| |

Working frequency | Hz | 500 |

| |

Melting rate | t/h | 3.5-4 | 1600℃,≥98% | |

Power consumption | kw.h/t | 550-630 | 1600℃,≥98% | |

Inductor inner diameter | mm | Φ1160 |

| |

hight of inductor | mm | 1880 |

| |

Rated temperature of the melting steel | ℃ | 1600 |

| |

Incoming voltage of MF cabinet | v | 1000 |

| |

electric rectificate mode |

| 12plus |

| |

Voltage of inductor | V | 3300 | Double voltage | |

Cooling water of the furnace | pressure of incoming water | Mpa | 0.25~0.3 |

|

temperature of incoming water | ℃ | 5~35 |

| |

temperature of the outlet water | ℃ | ≤55 |

| |

flow rate ( furnace body ) | t/h | 120 | single furnace 60 t/h | |

flow rate (power source) | t/h | 50 |

| |

water temperature rise of power source | ℃ | 10 |

| |

cooling water pressure for power source | Mpa | 0.1~0.2 |

| |

Hydrauic system | working pressure | Mpa | 12 |

|

flow rate | L/min | 60 |

| |

hydraulic medium |

| antiwear hydraulic oil | summer:N68 winter:N46 | |

diameter of the hydraulic cylinder | mm | Φ160 |

| |

Transformer | incoming voltage | KV | 35 |

|

secondary voltage | V | 1000 |

| |

Connection |

| Dd0yn11 |

| |

Impedance voltage |

| 8~9% |

| |

Phase |

| 3-phase input, 6-phase output |

| |

|

|

|

| |

KGSP technology with high quality middle frequency induction furnace machine is melting alloy steel .lower carbon steel working

The 5ton induction furnace is melting alloy steel .lower carbon steel working with CCM ,ROLLING MILL .

Electric tilting furnace,middle frequency induction furnace,steel shell hydraulic tilting medium frequency melting induction furnace for melting steel scrap ,iron scarp to produce bilelts ,bar,wire,angle bar ,rebar etc..

Our other main capacity specification

| MODEL(melting steel) | Input Voltage V | Input Current A | Rate Power KW |

| GW-0.01-50/1JJ | 380(6 Pulse ) | 76 | 50 |

| GW-0.03-100/1JJ | 380(6 Pulse ) | 160 | 100 |

| GW-0.05-100/1JJ | 380(6 Pulse ) | 160 | 100 |

| GW-0.08-100/1JJ | 380(6 Pulse ) | 160 | 100 |

| GW-0.15-100/1JJ | 380(6 Pulse ) | 160 | 100 |

| GW-0.25-160/1JJ | 380(6 Pulse ) | 256 | 160 |

| GW-0.3-250/1JJ | 380(6 Pulse ) | 400 | 250 |

| GW-0.5-250/1JJ | 380(6 Pulse ) | 400 | 250 |

| GW-0.5-250/1J | 380(6 Pulse ) | 400 | 250 |

| GW-0.75-400/1JJ | 380(6 Pulse ) | 650 | 400 |

| GW-0.75-400/1J | 380(6 Pulse ) | 650 | 400 |

| GW-1-500/1JJ | 380(6 Pulse ) | 800 | 500 |

| GW-1-750/1JJ | 380/690 | 1200/ | 750 |

| (6 Pulse ) | 700 | ||

| GW-1-750/1J | 380/690 | 1200/ | 750 |

| (6 Pulse ) | 700 | ||

| GW-1.5-1000/0.5JJ | 690(6 Pulse ) | 912 | 1000 |

| GW-1.5-1000/0.5J | 690(6 Pulse ) | 912 | 1000 |

| GW-2-1500/0.5JJ | 690(6 Pulse ) | 1360 | 1500 |

| GW-2-1500/0.5J | 690(6 Pulse ) | 1360 | 1500 |

| GW-2-2000/0.5JJ | 690(6 Pulse ) | 1400 | 2000 |

| GW-2-2000/0.5J | 690(6 Pulse ) | 1400 | 2000 |

| GW-3-2500/0.5JJ | 690/1000 | 2275/ | 2500 |

| (6 Pulse ) | 1700 | ||

| GW-3-2500/0.5J | 690/1000 | 2275/ | 2500 |

| (6 Pulse ) | 1700 | ||

| GW-4-3000/0.5J | 690/1000 | 2730/ | 3000 |

| (6 Pulse ) | 2040 | ||

| GW-5-4000/0.5JJ | 1000 | 2300/ | 4000 |

| (12 Pulse ) | 2700 | ||

| GW-5-4000/0.5J | 1000(12Pulse ) | 2300 | 4000 |

| GW-6-4000/0.5J | 1000(12 Pulse) | 2300 | 4000 |

| GW-8-5000/0.5J | 1000(12 Pulse) | 3400 | 5000 |

| GW-10-6000/0.5J | 1000(12 Pulse) | 3750 | 6000 |

| GW-12-8000/0.25J | 1000(12 Pulse) | 4900 | 8000 |

| GW-15-10000/0.25J | 1000(24 Pulse) | 6500 | 10000 |

| GW-18-12000/0.25J | 1000(24Pulse) | 8160 | 12000 |

| GW-20-12000/0.25J | 1000(24 Pulse) | 8160 | 12000 |

| GW-25-14000/0.25J | 1000(24 Pulse) | 9460 | 14000 |

| GW-30-16000/0.2J | 100024 Pulse) | 10850 | 16000 |

| GW-40-18000/0.2J | 1000(24 Pulse) | 12240 | 18000 |

| GW-50-20000/0.2J | 1000(24Pulse) | 14932 | 20000 |

- Q: Selection of heat preservation material for industrial furnace

- Ceramic fiber blanket can be used.Ceramic fiber blanket color white, regular size, set fire, heat insulation, insulation in one. Free from any binding agent.

- Q: What is the difference between industrial furnaces and boilers?

- Hot water or steam generated in the boiler can directly provide necessary energy for industrial production and people's life, but also by the steam power device is converted to mechanical energy, or through the generator converts mechanical energy into electrical energy. Hot water boilers are called hot water boilers. They are mainly used in daily life, and are also used in industrial production. Steam generating boilers are called steam boilers, often referred to as boilers. They are used in thermal power stations, ships, locomotives and industrial and mining enterprises.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- Each manufacturer has its own industry and technological advantages.If you say that the performance rankings, turnover, and so on, it seems that no one has done this ranking.

- Q: What are the combustion equipments used in industrial boilers?

- Main auxiliary equipment for general boilers:1. domestic appliances 2. civilian gas boiler 3. industrial gas furnace.

- Q: What is industrial furnace masonry?

- Masonry industrial furnaces refers to complete materials such as brick kilns in construction process.

- Q: What's the role of anchor bricks in industrial furnaces?

- Anchorage brick is a new type of anchor brick relates to an industrial furnace, in particular to anchor brick of an industrial furnace roof, including column hanging end and the anchor structure, opened in the anchor on the surface of the spacing of the grooves in the anchor on at least one surface is arranged along the length direction ribs is provided with ribs, the ribs of the reinforcement and anchorage tension, tensile and flexural strength was obviously improved, the stress generated in the groove at the bar at the barrier can not continue to transfer, so the anchor brick of this kind of structure is not easy to break.

- Q: Why does the burner of industrial furnace burn occasionally?

- The basic structure of the complete ignition system is the ignition device and flameout protection device. The ignition burner includes an ignition electrode and an igniter (equipped with some external type transformer, voltage transformer) through the above 10kV, the ignition electrode spark ignition of high voltage discharge to ignite gas column.

- Q: What is the difference between industrial furnace masonry and ordinary masonry?

- Industrial furnace masonry requirements are relatively high, industrial furnaces of different uses, whether material or masonry process, have strict requirements.

- Q: Brief introduction to repair of industrial furnace

- The industrial furnace is the main production equipment in the machinery industry. The repair of industrial furnace directly affects the quality, high yield, long life, low consumption and safe production of the furnace.

- Q: What is an industrial furnace pit?

- In twentieth Century 50s, coreless induction furnaces were developed rapidly. Later, electron beam kilns, using electron beams to impact solid fuels, strengthen the surface to heat and fuse materials with high melting point.

Send your message to us

Middle frequency induction furnace with parralel or series connection

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords