Medium Frequency Induction Furnace, Melting Furnace

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Plywood Cases |

| Delivery Detail: | 25days to 120days |

Specifications

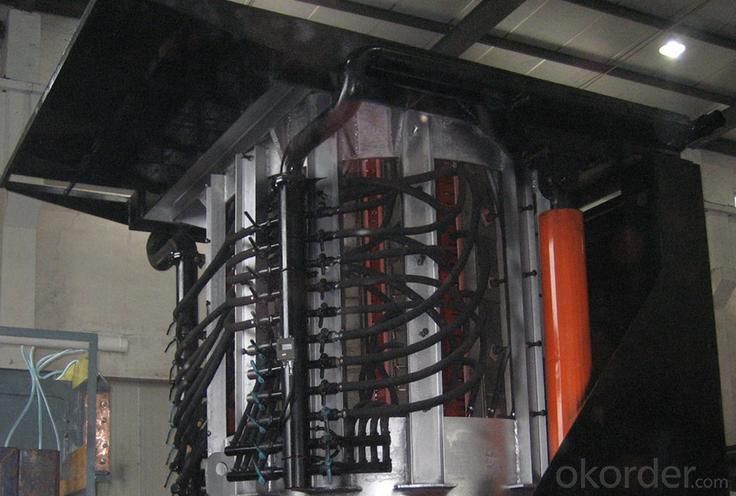

Medium Frequency Induction Furnace

Medium Frequency Melting Furnace

For melting steel, cast iron, stainless steel, copper

Coreless Medium Frequency Melting Furnace

· Application

2. Good magnetic isolation, safe and reliable;

3. Solid frequency conversion power supply, easy operation; Adjustable power rate, easy operation and maintenance;

4. Easy to start up with load or free of load.

1. Digital CMOS chip (U. S. ASIC-2-12), with the highest degree of integration at home, is used in control circuit, the overall machine controlled through one single panel;

2. Frequency-sweep zero voltage start, high success rate, no shock;

3. Automatic resistance adjustment, permanent power output, 10-20% energy saved in comparison with domestic traditional machine of the type;

4. Auto phase sequence adaptation, free of synchronization;

5. Good performance in reload staring, auto recovery;

6. Highly integrated in controlling circuit, free of use of high-rate starter and relay loop, fairly low failure rate;

7. Wholly digital design, strong in anti-interference, no temperature shift when in continuous working;

8. Multi-protection functions (for over current, over voltage, insufficient water pressure, power failure, or phase absence), and mishandling will not cause damage to machine.

· Model explanation ( GWG-1-750/1J for example}

GWG--------Steel Shell Medium Frequency Coreless Induction Furnace, Melting Furnace

-1-------Rated Capacity 1 Ton (1000kg)

-750-------Rated Power 750Kw

/1--------1000Hz (1KHz)

-J---------Hydraulic tilting

| Model | Input Power | Input Volt. | Incoming Curr. | Rated Power | DC Curr. | DC Volt. | Melting Rate | Working Freq. | Working Volt. | Rated Capacity | Power Consumption |

Kw | V/pulse | A | Kw | A | V | T/H | Hz | V | T | KWH/T | |

| GWG-0.5-250/1J | 280 | 380/6 | 400 | 250 | 500 | 500 | 0.4 | 1000 | 1500 | 0.5 | 770 |

| GWG-0.75-400/1J | 400 | 380/6 | 650 | 400 | 800 | 500 | 0.6 | 1000 | 1500 | 0.75 | 770 |

| GWG-1-750/1J | 800 | 380/6 | 1200 | 750 | 1500 | 500 | 0.9 | 1000 | 1500 | 1 | 720 |

| 690/6 | 700 | 850 | 880 | 500 | 2600 | 660 | |||||

| GWG-1.5-1000/0.5J | 1100 | 690/6 | 912 | 1000 | 1140 | 880 | 1.2 | 500 | 2600 | 1.5 | 700 |

| GWG-2-1500/0.5J | 1650 | 690/6 | 1360 | 1500 | 1700 | 880 | 1.7 | 500 | 2600 | 2 | 675 |

| GWG-3-2500/0.5J | 2750 | 690/6 | 2275 | 2500 | 2840 | 880 | 2.56 | 500 | 2600 | 3 | 610 |

| 950/6 | 1700 | 2080 | 1250 | 3200 | 560 | ||||||

| GWG-4-3000/0.5J | 3300 | 690/6 | 2730 | 3000 | 3410 | 880 | 3.2 | 500 | 2600 | 4 | 590 |

| 950/6 | 2040 | 2500 | 1250 | 3200 | 560 | ||||||

| GWG-5-4000/0.5J | 4400 | 950/6 | 2300 | 4000 | 3330 | 1250 | 5 | 500 | 3400 | 5 | 500/550 |

| GWG-6-4000/0.5J | 4400 | 950/12 | 2300 | 4000 | 3330 | 1250 | 5 | 500 | 3400 | 6 | 500/550 |

| GWG-8-5000/0.5J | 5000 | 950/12 | 3400 | 5000 | 4200 | 1250 | 7~8 | 500 | 3400 | 8 | 500/550 |

| GWG-10-6000/0.5J | 6300 | 950/12 | 3750 | 6000 | 4600 | 1250 | 9~10 | 500 | 3400 | 10 | 500/550 |

| GWG-12-8000/0.5J | 8000 | 950/12 | 4900 | 8000 | 6000 | 1250 | 10~11 | 500 | 3400 | 12 | 500-550 |

| GWG-12-8000/0.25J | 8000 | 950/12 | 4900 | 8000 | 6000 | 1250 | 10~11 | 250 | 3400 | 12 | 500-550 |

| GWG-15-8000/0.25J | 8000 | 950/12 | 4900 | 8000 | 6000 | 1250 | 9~10 | 250 | 3400 | 15 | 550-590 |

| GWG-15-10000/0.25J | 10000 | 950/24 | 6500 | 10000 | 8000 | 1250 | 13~14 | 250 | 3400 | 15 | 500-550 |

| GWG-18-12000/0.25J | 12000 | 950/24 | 8160 | 12000 | 10000 | 1200 | 13~14 | 250 | 3400 | 18 | 500-550 |

| GWG-20-12000/0.25J | 12000 | 950/24 | 8160 | 12000 | 10000 | 1200 | 13~14 | 250 | 3400 | 20 | 500-550 |

| GWG-25-14000/0.25J | 14000 | 950/24 | 9460 | 14000 | 11600 | 1200 | 13~15 | 150~200 | 3400 | 25 | 500-550 |

| GWG-30-16000/0.2J | 16000 | 950/24 | 10850 | 16000 | 13300 | 1200 | 15~16 | 150~200 | 3400 | 30 | 500-550 |

| GWG-40-18000/0.2J | 18000 | 950/24 | 12240 | 18000 | 15000 | 1200 | 20~22 | 150~200 | 3400 | 40 | 500-550 |

- Q: Selection of heat preservation material for industrial furnace

- In the neutral and oxidizing atmosphere, the tensile strength, toughness and fiber structure can be maintained for long term use. The temperature is 950-1400 centigrade. Excellent chemical stability; excellent thermal stability; excellent tensile strength; low thermal conductivity; low thermal capacity; excellent sound absorption and noise reduction performance.

- Q: What is the difference between industrial furnaces and boilers?

- A boiler is a mechanical device for heating water into hot water or steam by the use of heat from fuel or other sources of energy. The original meaning of a pot is a water container heated by fire. The furnace is the place where the fuel is burned. The boiler includes two parts, the cooker and the furnace.

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The main equipments of heat treatment are classified into two major categories: main equipment and auxiliary equipment. The main equipment includes heat treatment furnace, heating device, surface modification, surface oxidation device, surface mechanical enhancement device, cooling equipment, cold processing equipment, process parameter detection and control instrument; auxiliary equipment includes cleaning cleaning equipment, furnace atmosphere heating medium permeability meter preparation equipment, cooling device, quenching medium heavy transport machinery, quality testing equipment, power transmission line and auxiliary equipment, fire safety equipment, dust and other production fixture.

- Q: What are the combustion equipments used in industrial boilers?

- The boiler is an energy conversion equipment. The energy input to the boiler has the chemical energy and the electric energy in the fuel. The boiler outputs steam with certain heat energy and high temperature water.

- Q: What is industrial furnace masonry?

- Masonry industrial furnaces refers to complete materials such as brick kilns in construction process.

- Q: What's the role of anchor bricks in industrial furnaces?

- The wall of an industrial furnace or flue is mainly composed of an inner lining layer, a heat insulating layer and an outer wall layer. The lining is a refractory brick, and the outer wall is an ordinary sintered brick.

- Q: How many kinds of industrial electric furnaces are there?

- This series of electric furnace is made of super light refractory fiber. The electric stove and the temperature control cabinet matching use, the controller may automatically or the manual control electric stove temperature, may press the user request to provide the computer table or the computer control, does the multielement temperature measurement, guarantees the product quality. This series of electric furnaces are periodical operation type electric furnaces.

- Q: What is the difference between industrial furnace masonry and ordinary masonry?

- Of course, the difference is like the difference between a hog cap and a 100 story building. See the industrial furnace manual.

- Q: Brief introduction to repair of industrial furnace

- Although the number of industrial furnaces in general machinery plants is not large, the number of large repairs per year accounts for 16%-20% of the total number of repairs for all equipment, and the large repair costs account for about 18%-25% of the total repair cost of all equipment.

- Q: What is the difference in structure between industrial furnace and boiler?

- Industrial furnace: main heating, steel and other metal materials, or ore and other materials. An industrial furnace of higher temperature, such as forging or heat treatment. Therefore, the energy consumption is large, and the insulation layer is designed to be thicker, and the structure is designed for the final purpose of the production purpose, the product process and the production efficiency.

Send your message to us

Medium Frequency Induction Furnace, Melting Furnace

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords