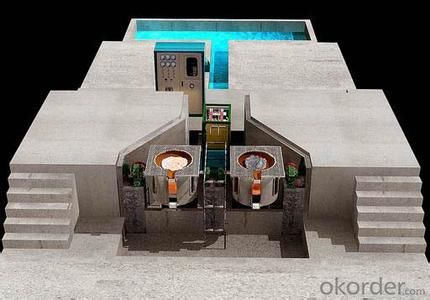

Vacuum IF (medium Frequency) Induction Furnace

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | induction melting furnace is packaged in Standard export wooden cases and containers |

| Delivery Detail: | 10-1500days |

Specifications

induction melting furnace

1.Factory inspection

2.Energy-saving

3.Free technical training and after-sale service

Vacuum metal metallurgy Induction Furnace/Melting Furnace

Specializing in this field for many years

High quality products and favorable prices

Quick delivery and satisfying service

Hot-selling all over the world

1.Introdution

The vacuum induction melting furnace is mainly applied to scientific research and industrial manufacture. In vacuum environment, this vacuum metal melting equipment utilizes medium-frequency induction heater to melt metals. Featuring small floor space, our industrial electric furnace delivers lucrative scientific research and industrial manufacture.

Our vacuum induction melting furnace is a batch-type furnace. This metal metallurgy equipment is greatly recommended for melting and casting of alloy steel, nickel-based alloy and rare earth element in vacuum or protective gas environment. It also finds applications in refining metals.

2.Technical parameters

| Model | Power | Frequency | Max. working temperature | Dried furnace capacity | Max. vacuum degree | Pressure rising rate | Medium-frequency power |

| EF-3 | 30kW | 4000HZ | 1650℃ | 3kg | 6.67× 10-3Pa | 6Pa/h | IGBT |

| EF-10 | 60kW | 1500HZ | 1650℃ | 10kg | 6.67× 10-3Pa | 6Pa/h | IGBT |

| EF-25 | 100kW | 2000HZ | 1650℃ | 25kg | 6.67× 10-3Pa | 6Pa/h | IGBT |

| EF-50 | 100kW | 1500HZ | 1650℃ | 50kg | 6.67× 10-3Pa | 6Pa/h | KGPS |

| EF-150 | 200kW | 1500HZ | 1650℃ | 150kg | 6.67× 10-3Pa | 6Pa/h | KGPS |

| EF-200 | 250kW | 2500HZ | 1600℃ | 200kg | 6.7×10-2Pa | 6Pa/h | KGPS |

- Q: What is the difference between industrial furnaces and boilers?

- A boiler is a mechanical device for heating water into hot water or steam by the use of heat from fuel or other sources of energy. The original meaning of a pot is a water container heated by fire. The furnace is the place where the fuel is burned. The boiler includes two parts, the cooker and the furnace.

- Q: Should the industrial furnace shell cool down?

- The function of furnace shell is beautiful, protective lining, fixed function accessories and so on.

- Q: What are the combustion equipments used in industrial boilers?

- The main auxiliary equipments of the general boiler are: upper coal machine, ash blower, blower, draught fan, economizer, feed pump and water treatment unit. Oil boilers are: oil pumps, burners, tanks and so on.

- Q: What is industrial furnace masonry?

- Plane construction must level, slope construction must find slope,refractory bricks must be selected and processed according to masonry requirements.

- Q: Why does the burner of industrial furnace burn occasionally?

- The flameout protection system is made up of burner controller, electromagnetic valve and flame detector, and the flame detection mode is mainly based on the two forms of ultraviolet detection and electrode detection. By utilizing the electric conductivity of the flame, the circuit path of the combustion process generates a weak current, and when the signal amplifier is amplified, the flame is induced to exist, and the small power burner adopts the detection mode more, and is economical and practical.

- Q: How many kinds of industrial electric furnaces are there?

- Electric furnace is divided into four categories: resistance furnace, induction furnace, arc furnace and special electric furnace according to the different ways of electric heating.

- Q: What is the difference between industrial furnace masonry and ordinary masonry?

- Industrial furnace masonry requirements are relatively high, industrial furnaces of different uses, whether material or masonry process, have strict requirements.

- Q: How to use industrial furnace equipment?

- If it is water cooling furnace door, but also to ensure the smooth flow of pipes, winter pipes are not frozen. When the boiler is in a limited position, the interlocking device for cutting off the power supply shall be provided when the furnace is in and out, and the number of broken wires in the pitch of the steel wire shall not exceed 10%, and the counterweight of the furnace door shall be reliably hung.

- Q: What is the difference in structure between industrial furnace and boiler?

- From the way: industrial furnace (electricity, natural gas, gas, induction heating is considered electricity), boilers (coal, all kinds of hot exhaust gas, a variety of gas, seemingly less electricity).

- Q: What is an industrial furnace pit?

- In twentieth Century 50s, coreless induction furnaces were developed rapidly. Later, electron beam kilns, using electron beams to impact solid fuels, strengthen the surface to heat and fuse materials with high melting point.

Send your message to us

Vacuum IF (medium Frequency) Induction Furnace

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches