Submerged Arc Furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Submerged Arc Furnace

Submerged Arc Furnace Profile

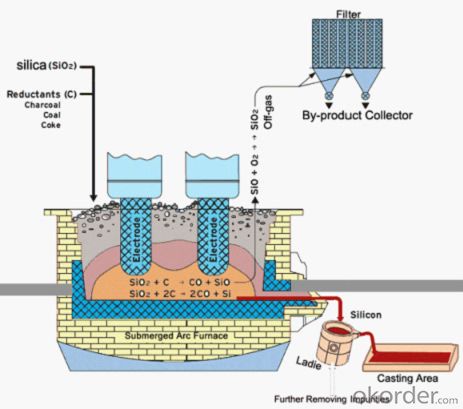

Submerged arc furnace—it’s also known as electric arc furnace or resistance electric furnace. It is mainly used to reducing smelting ore, carbonaceous reducing agent and solvent etc. Mainly adapts to production of ferrosilicon, ferromanganese, ferrochrome, ferrotungsten, silicon manganese alloy and other ferrous alloys, it is an important smelting furnace in metallurgical industry for production of industrial raw materials and calcium carbide and so on chemical raw materials. The working character is to use carbon or magnesia refractory materials as furnace lining, use self roasting electrode. Electrode inserts into the materials inside the furnace for submerged arc operation, using arc energy and current through the materials, and due to the resistance of the materials and produce energy to melt metal. It’s a kind of industrial furnace which is worked continuously, charged material in succession, and tapped out metal or slag in intermittent.

Submerged Arc Furnace---Major categories and application

Category | Main raw-material | Final products | Reaction | Power | ||

Ferroalloy | Ferrosilicon | (45%) | Ferrosilicon, | Ferrosilicon | 1550-1770 | 2100-5500 |

(75%) | 8000-11000 | |||||

Ferromanganese furnace | Manganese | Ferromanganese | 1500-1400 | 2400-4000 | ||

Ferrochrome furnace | Chrome ore, | Ferrochrome | 1600-1750 | 3200-6000 | ||

Ferrotungsten furnace | Tungsten | Ferrotungsten | 2400-2900 | 3000-5000 | ||

Silicon chromium furnace | Ferrochrome, | Silicon chrome | 1600-1750 | 3500-6500 | ||

Silicon manganese furnace | Manganese | Silicon | 1350-1400 | 3500-4000 | ||

Steelmaking electric furnace | Iron ore, coke | Pig iron | 1500-1600 | 1800-2500 | ||

Calcium carbide furnace | Limestone, coke | Calcium carbide | 1900-2000 | 2900-3200 | ||

Boron carbide furnace | Boron oxide, | Boron carbide | 1800-2500 |

| ||

Notes: The above is roughly value. According to the difference of the raw material composition, finished product components, electric furnace capacity and etc. the power consumption value will be much different.

Submerged Arc Furnace---Structure characteristics

Submerged arc furnace is a kind of industrial furnace which consumes much power. Full set equipment mainly consists of furnace shell, fume hoods, lining, short net, cooling system, exhaust system, de-dusting system, electrode shell, electrode lifting system, loading and unloading system, electrode holder, arc burner, hydraulic systems, submerged arc furnace transformer and various of electrical equipments.

Submerged arc furnace equipment is divided into three layer arrangement

The 1st layer is furnace body (including furnace bottom support, furnace shell, furnace lining), tapping system (including the ladle and ladle car.), arc burner etc.

The 2nd layer

1、Fume hood: At present, mostly of submerged arc furnace adopts closed or semi-closed low hood structure, with the characteristics of environmental protection, facilitate maintenance and improve the operation environment. The closed structure can also collect the exhaust gas (main ingredient is carbon monoxide) which is generated in the production and used in synthetically. Also can reduce the heat loss of the circuit, decrease the temperature of the electrode, and improve the operating environment.

2、Electrode holder: Most of submerged arc furnace with three-phase power supply. Electrode in triangle or inverted triangle, symmetrical position placed in the middle of furnace chamber. Large submerged arc furnace generally adopts anthracite, coke and coal tar pitch mixed as electrode material, in the process of smelting , it roasting by itself as electrode.

3、Short net

4、Copper tile

5、Electrode shell

6、Unloading system

7、Stoking machine

8、Fume exhaust system

9、Water-cooling system

10、Submerged arc furnace transformer

11、Operating system

The 3rd layer

1、Hydraulic system

2、Electrode press and release device

3、Electrode lifting system

4、Steel platform

5、Hopper and cycle material distribution car

Other additional: skew Bridge feeding system, electronic batching system, etc.

- Q: What is the difference between industrial furnaces and boilers?

- Industrial kilns and industrial furnaces are collectively referred to as industrial furnaces. Industrial furnaces mainly refer to devices that heat materials by combustion reactions.

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The general metal die casting plant and the metal smelting plant need process melting and dissolving furnace, usually there are reverberatory furnace, cupola, rotary furnace, etc. I do the melting furnace of aluminium alloy.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- Basically, no industrial furnace manufacturer can do all types of stoves.Often associated with the industry is very large,so your ranking is basically meaningless.

- Q: What is industrial furnace masonry?

- Masonry industrial furnaces refers to complete materials such as brick kilns in construction process.

- Q: What's the role of anchor bricks in industrial furnaces?

- The wall of an industrial furnace or flue is mainly composed of an inner lining layer, a heat insulating layer and an outer wall layer. The lining is a refractory brick, and the outer wall is an ordinary sintered brick.

- Q: How many kinds of industrial electric furnaces are there?

- Industrial furnace according to the heating mode is divided into two categories: one is the fuel furnace, combustion heat with solid, liquid or gaseous fuel in the furnace for heating the workpiece; the second is in the furnace, the furnace converts electrical energy to heat the heat.

- Q: What are the advantages of a vacuum furnace?

- The accuracy of furnace temperature measurement and monitoring is obviously improved. The indicating temperature of the thermocouple and the temperature of the furnace reach 1.5 C. But there is a large temperature difference in a large number of workpieces in different parts of the furnace. If the forced circulation of the rarefied gas is adopted, the temperature range of the temperature range of + 5 DEG C can still be controlled.

- Q: How to use industrial furnace equipment?

- When the furnace is used, the lifting mechanism of the furnace door must be in good condition, and the wire breakage of the steel wire is not allowed to exceed the designated value. The weight should be properly allocated, and the drive department shall be provided with a protective cover.

- Q: Brief introduction to repair of industrial furnace

- The working condition of industrial furnace is very bad. It is affected by high temperature, slag erosion and burden wear. Therefore, its working condition changes quickly and its service life is short.

- Q: What is the difference in structure between industrial furnace and boiler?

- At the same time, the working environment is relatively poor, the structure should be sturdy and durable, the transfer mechanism (generally) to stable and durable low failure rate, the insulation layer must be thick enough and the economy, the steel structure housing materials used to be enough.

Send your message to us

Submerged Arc Furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords