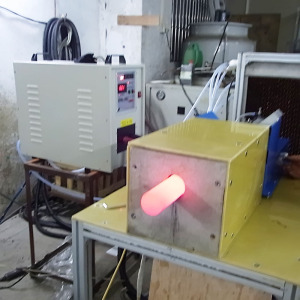

Steel Melting Furnace (GW-5T)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Advantage:

1. 20-30% power saving

2. 20 years of experience

3. High speed

4. Low consumption

5. ISO&CE certificate

6. Easy operation and maintenance

7. Leading technology.

Application of Steel Melting Furnace

Intermediate Frequency Electrical Melting Furnace, also called as Induction Smelting Furnace, which converting three phase power current into single phase intermediate frequency current and enabling metal to produce eddy current loss through electromagnetic field induction to achieve heating and melting. It is applicable to melting, heating or insulting of steel, copper, iron, aluminum, zinc, tin, nickel silver and other ferrous, nonferrous metal. It can also be used for other heating treatment before forging, sintering and tube-bending forming in the casting and melting industries.

Performances and Features

1. Adopt a zero-voltage scanning soft-start mode, it can be started or stopped in any case and at any time, so it has no impact on power supply.

2. Fast smelting with low production cost; Low-pollution and environment-friendly;

3. Start melting from cold furnace. Solution can be fully empty. Change molten material easily.

4. Power adjustment is flexible. Be able to adjust continuously and smoothly. Temperature is even and can be easily controlled. Less oxidation burning. Metal components is even.

5. Furnace shell is adopt aluminum alloy or steel structure, covering small area; Convenience to overturn the furnace, according to your need to adpot overturing way like electric, manual, hydraulic.

6. It can automatically adjust to match the load impedance, The equipment will always run in good working condition without adjustment of compensation capacitance, low fault rate; Power supply system has diagnostic error function that make it easy to check and maintenance.

7. Suitable for intermittent production.

IF Furnace constitution

1. Furnace body2. Medium frequency power supply

3. Water cooling cable

4. Reduction machine

5. Crucible mold

6. Compensation capacitor rack

2. 20 years of experience

3. High speed

4. Low consumption

5. ISO&CE certificate

6. Easy operation and maintenance

7. Leading technology.

8. Best price

Application of Steel Melting Furnace

Intermediate Frequency Electrical Melting Furnace, also called as Induction Smelting Furnace, which converting three phase power current into single phase intermediate frequency current and enabling metal to produce eddy current loss through electromagnetic field induction to achieve heating and melting. It is applicable to melting, heating or insulting of steel, copper, iron, aluminum, zinc, tin, nickel silver and other ferrous, nonferrous metal. It can also be used for other heating treatment before forging, sintering and tube-bending forming in the casting and melting industries.

Performances and Features

1. Adopt a zero-voltage scanning soft-start mode, it can be started or stopped in any case and at any time, so it has no impact on power supply.

2. Fast smelting with low production cost; Low-pollution and environment-friendly;

3. Start melting from cold furnace. Solution can be fully empty. Change molten material easily.

4. Power adjustment is flexible. Be able to adjust continuously and smoothly. Temperature is even and can be easily controlled. Less oxidation burning. Metal components is even.

5. Furnace shell is adopt aluminum alloy or steel structure, covering small area; Convenience to overturn the furnace, according to your need to adpot overturing way like electric, manual, hydraulic.

6. It can automatically adjust to match the load impedance, The equipment will always run in good working condition without adjustment of compensation capacitance, low fault rate; Power supply system has diagnostic error function that make it easy to check and maintenance.

7. Suitable for intermittent production.

IF Furnace constitution

1. Furnace body2. Medium frequency power supply

3. Water cooling cable

4. Reduction machine

5. Crucible mold

6. Compensation capacitor rack

| Furnace Capacity | Rating Power | Input Voltage | Input Phase | Input Current | Assorted Transformer | Output Voltage | Output Frequency | Melting Time | Volume | Weight |

| GW-0.05T | 50KW | 380V | 3 | 80A | 60KVA | 750V | 2.5KHZ | 20-60Min | 1.2 m³ | 350KG |

| GW-0.1T | 100KW | 380V | 3 | 160A | 120KVA | 750V | 1KHZ | 20-60Min | 6 m³ | 1500KG |

| GW-0.15T | 100KW | 380V | 3 | 160A | 120KVA | 750V | 1KHZ | 30-70Min | 6.5m³ | 1600KG |

| GW-0.2T | 120KW | 380V | 3 | 192A | 150KVA | 750V | 1KHZ | 30-70Min | 7.5m³ | 1700KG |

| GW-0.3T | 130KW | 380V | 3 | 208A | 150KVA | 750V | 1KHZ | 30-70Min | 8.5m³ | 1800KG |

| GW-0.4T | 250KW | 380V | 3 | 400A | 315KVA | 750V | 1KHZ | 30-70Min | 9.5m³ | 2300KG |

| GW-0.6T | 350KW | 380V | 3 | 560A | 400KVA | 750V | 1KHZ | 40-80Min | 11m³ | 2500KG |

| GW-0.75T | 450KW | 380V | 3 | 720A | 500KVA | 750V | 1KHZ | 40-80Min | 12m³ | 3800KG |

| GW-1T | 600KW | 380V 380V-2 | 3/6 | 960A 480A | 600KVA 800KVA | 750V 1300V | 0.8KHZ | 50-90Min | 13m³ | 4500KG |

| GW-1.25T | 800KW | 380V 380V-2 | 3/6 | 1280A 640A | 800KVA 1250KVA | 750V 1300V | 0.8KHZ | 50-90Min | 14m³ | 5000KG |

| GW-1.5T | 1000KW | 380V 380V-2 | 3/6 | 1600A 800A | 1250KVA 1500KVA | 750V 1300V | 0.8KHZ | 50-90Min | 15m³ | 5500KG |

| GW-2T | 1250KW | 660V 380V-2 | 3/6 | 1120A 1000A | 1500KVA 1800KVA | 1300V | 1300V | 50-90Min | 17m³ | 6000KG |

| GW-3T | 1500KW | 660V 380V-2 | 3/6 | 1350A 1200A | 1800KVA 2000KVA | 1300V | 1300V | 60-100Min | 20m³ | 7000KG |

| GW-5T | 2500KW | 1000V 660V-2 | 3/6 | 2000A 1120A | 3000KVA 3500KVA | 1300V | 1300V | 60-100Min | 23m³ | 8500KG |

- Q: Selection of heat preservation material for industrial furnace

- In the neutral and oxidizing atmosphere, the tensile strength, toughness and fiber structure can be maintained for long term use. The temperature is 950-1400 centigrade. Excellent chemical stability; excellent thermal stability; excellent tensile strength; low thermal conductivity; low thermal capacity; excellent sound absorption and noise reduction performance.

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- Heat treatment furnace is mainly for the mechanical processing and casting industry workpiece annealing, quenching, carburizing, quenching and tempering, heat treatment equipment.

- Q: What are the combustion equipments used in industrial boilers?

- The main auxiliary equipments of the general boiler are: upper coal machine, ash blower, blower, draught fan, economizer, feed pump and water treatment unit. Oil boilers are: oil pumps, burners, tanks and so on.

- Q: What is industrial furnace masonry?

- Masonry industrial furnaces refers to complete materials such as brick kilns in construction process.

- Q: What's the role of anchor bricks in industrial furnaces?

- The wall of an industrial furnace or flue is mainly composed of an inner lining layer, a heat insulating layer and an outer wall layer. The lining is a refractory brick, and the outer wall is an ordinary sintered brick.

- Q: Why does the burner of industrial furnace burn occasionally?

- The basic structure of the complete ignition system is the ignition device and flameout protection device. The ignition burner includes an ignition electrode and an igniter (equipped with some external type transformer, voltage transformer) through the above 10kV, the ignition electrode spark ignition of high voltage discharge to ignite gas column.

- Q: How many kinds of industrial electric furnaces are there?

- This series of electric furnace is made of super light refractory fiber. The electric stove and the temperature control cabinet matching use, the controller may automatically or the manual control electric stove temperature, may press the user request to provide the computer table or the computer control, does the multielement temperature measurement, guarantees the product quality. This series of electric furnaces are periodical operation type electric furnaces.

- Q: How to use industrial furnace equipment?

- If it is water cooling furnace door, but also to ensure the smooth flow of pipes, winter pipes are not frozen. When the boiler is in a limited position, the interlocking device for cutting off the power supply shall be provided when the furnace is in and out, and the number of broken wires in the pitch of the steel wire shall not exceed 10%, and the counterweight of the furnace door shall be reliably hung.

- Q: What is the difference in structure between industrial furnace and boiler?

- At the same time, the working environment is relatively poor, the structure should be sturdy and durable, the transfer mechanism (generally) to stable and durable low failure rate, the insulation layer must be thick enough and the economy, the steel structure housing materials used to be enough.

- Q: What is an industrial furnace pit?

- In twentieth Century 50s, coreless induction furnaces were developed rapidly. Later, electron beam kilns, using electron beams to impact solid fuels, strengthen the surface to heat and fuse materials with high melting point.

Send your message to us

Steel Melting Furnace (GW-5T)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords