Metallic Material Steel Rebar/ Deformed Steel Bar/Iron Rods for Construction Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

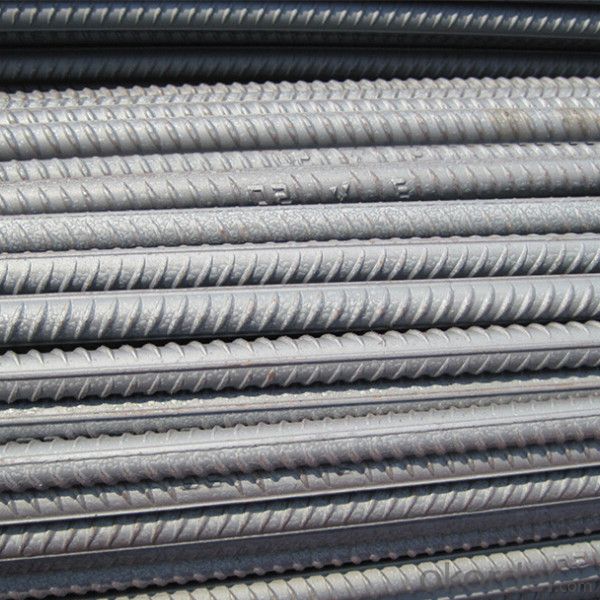

Metallic Material Steel Rebar/ Deformed Steel Bar/Iron Rods for Construction Concrete

Products Description:

Rebar is common known as steel reinforcing bar, usually applied to reinforced concrete and reinforced masonry structures. Formed from mild steel, it is given ribs for better frictional adhesion to the concrete. In other words rebar is an iron rod, a weldable plain reinforcing steel bar, that it can be also used for steel meshes.

1. Diameter: 5.5mm-10mm rounds reinforcing steel bar

10m- 40 rods reinforcing deformed steel bar

2. Length: 6m, 9m, 12m or customized

3. Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN. OEM technology - send detailed technical parameters for accurate quotation.

4. Produce Process: smelt iron - EAF smelt billet - ESR smelt billet - hot rolled or forged to get the steel round bar and plate

5. Heat Treatment: annealing, normalizing, tempering, quenching

6. Surface Treatment: Black

7. Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Theoretical weight and section area:

| Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m bar(kg) |

6 | 28.27 | 0.222 | 2.664 |

| 8 | 50.27 | 0.395 | 4.74 |

| 12 | 113.1 | 0.888 | 10.656 |

| 16 | 201.1 | 1.58 | 18.96 |

| 20 | 314.2 | 2.47 | 29.64 |

| 25 | 490.9 | 3.85 | 46.2 |

| 32 | 804.2 | 6.31 | 75.72 |

| 40 | 1257 | 9.87 | 118.44 |

| 50 | 1964 | 15.42 | 185.04 |

Technical Datas:

Grade | Technical data of the original chemical composition (%) | |||||

| C | Mn | Si | S | P | V | |

| ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

HRB400 | Physical capability | |||||

| Yield Strength (N/cm²) | Tensile Strength (N/cm²) | Elongation (%) | ||||

| ≥400 | ≥570 | ≥14 | ||||

Products Show:

Packages and Shipping:

| Packaging | A seaworthy pachaging or as per customer required |

| Shipping | 10- 30days after we receive 30% deposite |

FAQ:

1. Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Payment Terms?

30% TT as deposit and 70% before delivery. Or Irrevocable L/C at sight.

4. Trading Terms?

EXW, FOB, CIF, FFR, CNF

5. After-sale Service

We provide the services and support you need for every step of our cooperation. We're the business partner you can trust. For any problem, please kindly contact us at any your convenient time.

- Q: How do steel rebars contribute to the ductility of reinforced concrete structures?

- Steel rebars contribute to the ductility of reinforced concrete structures by providing reinforcement and increasing tensile strength. The rebars act as a skeleton within the concrete, absorbing and distributing external forces such as tension and compression. This reinforcement prevents the concrete from cracking or failing under stress, allowing the structure to withstand greater loads and deform without collapsing, thus enhancing its overall ductility.

- Q: What is the average lifespan of a reinforced concrete structure with steel rebars?

- The average lifespan of a reinforced concrete structure with steel rebars can vary depending on various factors such as the quality of construction, maintenance, exposure to environmental conditions, and usage patterns. However, with proper design, construction, and maintenance, reinforced concrete structures with steel rebars can have an average lifespan of 50 to 100 years or more. Reinforced concrete structures are known for their durability and strength due to the combination of concrete and steel reinforcement. The concrete provides compressive strength, while the steel rebars provide tensile strength, making the structure resistant to various loads and forces. However, over time, reinforced concrete structures may experience degradation due to factors such as exposure to moisture, chemicals, temperature changes, and loading conditions. These factors can lead to the corrosion of steel rebars, which is a common concern for the longevity of such structures. Corrosion occurs when moisture and oxygen penetrate the concrete, causing the steel rebars to rust. This rusting process can lead to the expansion of the steel rebars, causing cracks in the concrete and further accelerating the deterioration of the structure. To mitigate the effects of corrosion and extend the lifespan of reinforced concrete structures, various measures can be taken. These include using high-quality concrete and steel rebars, applying protective coatings, implementing proper drainage systems, and conducting regular inspections and maintenance. With appropriate maintenance and upkeep, reinforced concrete structures can last well beyond their average lifespan. However, it is crucial to note that the lifespan can vary depending on specific conditions and circumstances. Therefore, it is essential to consult with structural engineers and industry professionals to assess and determine the expected lifespan of a particular reinforced concrete structure.

- Q: Can steel rebars be used in the construction of stadiums for indoor sports?

- Yes, steel rebars can be used in the construction of stadiums for indoor sports. Steel rebars provide structural strength and reinforcement to concrete, making them suitable for supporting the heavy loads and ensuring the stability of the structure.

- Q: How do steel rebars contribute to the seismic performance of concrete buildings?

- The seismic performance of concrete buildings is greatly enhanced by steel rebars. These rebars provide reinforcement to the concrete structures, making them more resistant to the powerful forces exerted during an earthquake. Without proper reinforcement, the concrete can crack or collapse under the intense shaking. To strengthen the concrete and mitigate the effects of seismic activity, steel rebars are strategically placed within the concrete, forming a network that increases the tensile strength of the structure. Concrete is strong when compressed but weak when subjected to tension, while steel has excellent tensile strength. By combining the two materials, the rebars effectively distribute the seismic forces throughout the concrete, preventing cracks from spreading and allowing for a more flexible response. Not only do steel rebars improve the tensile strength, but they also enhance the overall stiffness of the structure. This stiffness helps to minimize the building's response to vibrations during an earthquake, reducing the potential for damage. Acting as a backbone, the rebars increase the concrete's resistance to deformation and contribute to the overall structural integrity of the building. Furthermore, steel rebars contribute to the ductility of the structure. Ductility refers to a material's ability to deform under stress without losing its structural integrity. During an earthquake, the building undergoes significant displacement and deformation. Steel rebars allow the concrete to flex and absorb the energy from seismic forces, preventing catastrophic failure. This ductile behavior ensures that the building can withstand the shaking and provides occupants with more time to evacuate safely. In conclusion, steel rebars are essential for improving the seismic performance of concrete buildings. They enhance the tensile strength, stiffness, and ductility of the structure, reducing the risk of damage or collapse during an earthquake. By reinforcing the concrete, steel rebars play a critical role in ensuring the safety and resilience of concrete buildings in areas prone to seismic activity.

- Q: What are the advantages of using galvanized steel rebars?

- There are several advantages to using galvanized steel rebars. Firstly, galvanized steel rebars have a protective zinc coating that helps prevent corrosion, extending the lifespan of the rebars and increasing the durability of the overall structure. This makes them ideal for construction projects in areas with high humidity, coastal regions, or where the structure will be exposed to chemicals or other corrosive elements. Additionally, galvanized steel rebars have high tensile strength, meaning they can withstand heavy loads and provide excellent structural support. They are also cost-effective as they require less maintenance and replacement over time compared to other materials. Overall, the use of galvanized steel rebars offers improved longevity, strength, and cost-efficiency, making them a popular choice in construction projects.

- Q: What is the effect of exposure to chemicals on the durability of steel rebars?

- Exposure to chemicals can have a detrimental effect on the durability of steel rebars. Chemicals, such as acids or salts, can lead to corrosion and the formation of rust on the surface of rebars. This corrosion weakens the structure and compromises its integrity, reducing the lifespan and load-bearing capacity of the rebars. Regular inspection, maintenance, and protective coatings are crucial to mitigate the negative impact of chemical exposure and ensure the long-term durability of steel rebars.

- Q: Can steel rebars be used in the construction of shopping malls?

- Yes, steel rebars can be used in the construction of shopping malls. Steel rebars provide structural strength and reinforcement to concrete, making them suitable for use in various construction projects, including shopping malls.

- Q: What are the different types of steel rebars used in elevated highways?

- The different types of steel rebars used in elevated highways include carbon steel rebars, epoxy-coated rebars, galvanized rebars, and stainless steel rebars.

- Q: Can steel rebars be used in retaining walls and dams?

- Yes, steel rebars can be used in retaining walls and dams. Steel rebars are commonly used in construction projects as reinforcement to provide strength and stability to concrete structures. In retaining walls and dams, where the primary objective is to withstand high pressure and heavy loads, steel rebars are often incorporated to enhance the structural integrity and durability of these structures.

- Q: Can steel rebars be used in foundation repair work?

- Yes, steel rebars can be used in foundation repair work. They are commonly used to reinforce concrete foundations, providing added strength and stability to the structure. Steel rebars help prevent cracks and structural damage in the foundation, making them an essential component in foundation repair projects.

Send your message to us

Metallic Material Steel Rebar/ Deformed Steel Bar/Iron Rods for Construction Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords