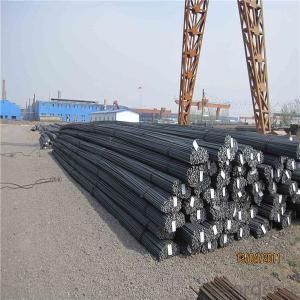

High Tensile Deformed Steel Rebar/Iron Rods for Building Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,ASTM,JIS,GB,BS,DIN,API,EN

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,BV,IBR,RoHS,CE,API,BSI,UL

Thickness:

6-34mm

Width:

6-34mm

Length:

12m

Outer Diameter:

6-34mm

Net Weight:

10kg

Packaging:

seaworthy packaging

High Tensile Deformed Steel Rebar/Iron Rods for Building Construction

Details of the High Tensile Deformed Steel Rebar/Iron Rods for Building Construction

| Standard & Grade: | GB1499-98 : HRB335,HRB400,HRB500 |

| BS4449-1997 : GR460,GR500 | |

| CAN/CSA-G30.18-M92 : 400W | |

| ASTM A615 : Gr.40, Gr.60 | |

| Diameter: | 6mm;8mm;10mm;12mm;14mm;16mm;18mm;20mm;22mm;25mm;28mm;30mm;32mm;35mm;40mm |

| Length: | 6m,9m,12m |

| Packing: | Bundle packing |

| Origin: | China |

| Application: | Construction,Road,Machinery processing,Welding fields. |

| Delivery time: | 10-25 days |

| Shipment: | By bulk vessel or Container |

| Documents: | Mill Test Certificate,Commercial Invoice,Packing List,Certificate of Origin |

Company Introduction of the High Tensile Deformed Steel Rebar/Iron Rods for Building Construction

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of the High Tensile Deformed Steel Rebar/Iron Rods for Building Construction

| Packaging Detail | Sea worthy packing /as per customer's packing instruction |

| Delivery Detail | 15 ~ 40 days after receiving the deposit |

FAQ

| Are you a trading company or manufacturer? | Manufacturer |

| What’s the MOQ? | 1000m2 |

| What’s your delivery time? | 15-20 days after downpayment received |

| Do you Accept OEM service? | Yes |

| what’s your delivery terms? | FOB/CFR/CIF |

| What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

| Western Union acceptable for small amount. | |

| L/C acceptable for large amount. | |

| Scrow ,Paybal,Alipay are also ok | |

| Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

| What's your available port of Shipment? | Main Port, China |

| What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

| Where are your Market? | Covering more than 160 countries in the world |

- Q: Excuse me, the difference between round steel, screw steel, steel, plate material, steel wire, hope professional answer

- Disk and rebar with rib, have all the same, basically can not see, rebar size is more than Phi 9, a lot of hardness than wire reinforced strong general, so the steel strip is usually linear, bluntly, steel disc is not up, disc. The size can be intercepted, so can be screwed up disc.

- Q: Why is the earthing device forbidden to use thread steel instead of round steel as lap steel bar?

- Steel is known as hot rolled ribbed bar. Ordinary hot rolled steel bars are made up of HRB and the minimum yield point of the brand.

- Q: Can steel rebars be recycled after the demolition of a structure?

- Yes, steel rebars can be recycled after the demolition of a structure. Steel is one of the most commonly recycled materials in the world, and rebars are no exception. During the demolition process, rebars are typically removed from the structure and separated from other materials such as concrete. The rebars are then collected and sent to a recycling facility where they are processed and melted down. The melted steel can be used to create new rebars or other steel products, reducing the need for virgin steel production and conserving valuable resources. Recycling rebars not only helps to reduce waste and minimize environmental impact but also contributes to the circular economy by promoting the reuse of materials.

- Q: Can steel rebars be used in precast or prestressed concrete?

- Yes, steel rebars can be used in both precast and prestressed concrete. Rebars are commonly used in these construction methods to provide reinforcement and enhance the strength and durability of the concrete structures.

- Q: Can steel rebars be used in tunnels or underground transportation systems?

- Yes, steel rebars can be used in tunnels or underground transportation systems. They are commonly used as reinforcement in concrete structures to enhance their strength and durability. Steel rebars help to withstand the pressure and stresses exerted on the tunnel or underground transportation system, making them a suitable choice for such applications.

- Q: How do steel rebars affect the overall strength of a structure?

- Steel rebars significantly enhance the overall strength of a structure by providing reinforcement and increasing its tensile strength. They act as a skeleton within the concrete, distributing the load more evenly and preventing cracks or failures.

- Q: Can steel rebars be used in the renovation of historic structures?

- The utilization of steel rebars is possible in the restoration of historical edifices. In construction endeavors, it is customary to employ steel rebars to fortify and enhance the stability of buildings, including those with historical significance. Throughout the renovation of historical structures, it is imperative to uphold the original essence and integrity of the edifice, whilst guaranteeing its stability and safety. By strategically incorporating steel rebars into the renovation process, it is feasible to reinforce fragile areas, strengthen load-bearing components, and extend the structure's lifespan without compromising its historical value. Nevertheless, it is vital to collaborate with competent architects, engineers, and preservationists who possess expertise in historical preservation. This ensures that the implementation of steel rebars is executed in a manner that respects the original design and materials of the historical structure.

- Q: What are the guidelines for the proper curing of concrete with steel rebars?

- The guidelines for the proper curing of concrete with steel rebars include ensuring a moist and controlled environment for the concrete to cure. This can be achieved by covering the concrete with a plastic sheet or using curing compounds. It is important to avoid rapid drying or exposure to extreme temperatures during the curing process. Additionally, regular monitoring of the curing process and proper hydration of the concrete are crucial to ensure the rebars bond effectively with the concrete and achieve maximum strength.

- Q: How do steel rebars improve the strength of concrete?

- Steel rebars improve the strength of concrete by providing reinforcement and resistance to tension forces. They are embedded within the concrete, forming a strong bond with it, and help to distribute loads and prevent cracks from spreading. The addition of steel rebars enhances the structural integrity and durability of concrete structures, making them more resistant to bending, shearing, and other forms of deformation.

- Q: How are steel rebars used in pre-stressed concrete structures?

- Steel rebars are used in pre-stressed concrete structures to provide tensile strength and reinforcement. They are typically placed in the concrete before it is poured and are then tensioned to withstand the loads and stresses that the structure will encounter. This pre-stressing process helps to enhance the overall strength and durability of the concrete, making it capable of withstanding greater loads and reducing the risk of cracking or failure.

Send your message to us

High Tensile Deformed Steel Rebar/Iron Rods for Building Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords