HVAC Aluminum Coils - Alloy 1050, 1100, 3003 Mill Finish Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

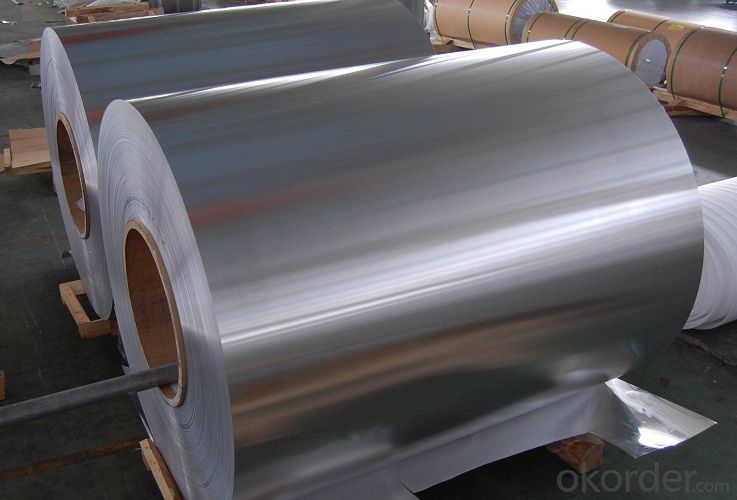

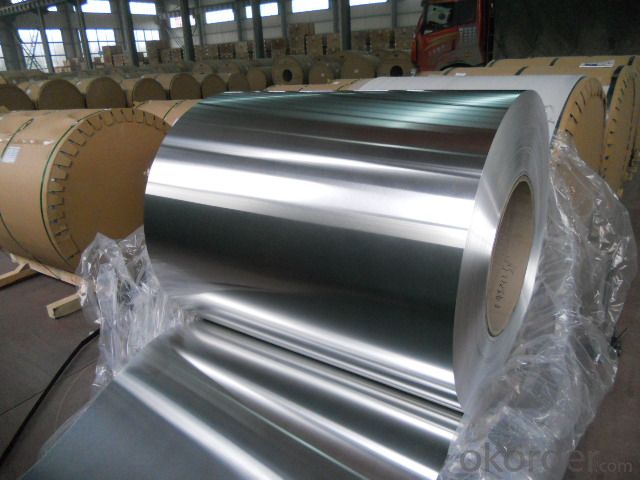

Alloy 1050,1100, 3003 Mill Finish Aluminum Coil

l Product Introduction

Aluminium Coil is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

l Product Specification

Perforated/Slitting Mill Finish Aluminum Strip Coil | |

Grade and Temper | Alloys: 1050, 1100, 3003, 3004 3005, 3105, 5005, 5052, 6061,6083, 8011,etc Temper: 0-H112 |

Widths | 35mm – 2,450 mm available |

Thickness | 0.09mm – 150mm |

Treatment | Mill Finish |

Coil Specifications | I.D.: 405mm, 505mm O.D.: 800mm - 1270mm |

Packing Detail | Wooden pallet either eye to wall or eye to sky |

Application | Perforated Aluminum Ceiling Panel, Conner Bead, sifter for mechanical equipment and Fencing, etc. |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advanced payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium coil is one of the popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality color coated aluminium coil to the world.

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What are the common sizes and thicknesses of aluminum coils?

- Common sizes and thicknesses of aluminum coils vary depending on the specific application and industry. However, there are some standard sizes and thicknesses that are commonly used across various industries. In terms of size, aluminum coils typically range from around 12 inches to 72 inches in width. This range allows for flexibility in accommodating different production processes and equipment. The length of the coils can vary as well, but it is often in the range of 1000 to 6000 feet. As for thickness, aluminum coils come in various gauges, which are commonly measured in inches or millimeters. The most commonly used thicknesses for aluminum coils are between 0.019 inches (0.48 mm) and 0.125 inches (3.18 mm). These thicknesses are suitable for a wide range of applications, including roofing, construction, automotive, and manufacturing. It is important to note that these are general guidelines, and the specific size and thickness requirements may vary depending on the intended use of the aluminum coils. Additionally, custom sizes and thicknesses can also be manufactured to meet specific project requirements.

- Q: Difference between aluminium roll gate and iron roll gate

- Structurally, there is no difference, but the aluminum roll gate weight is light, the motor needs little effect, save power; and the iron roll gate weight, motor power, electricity, but the door of high strength, better safety performance.

- Q: I take an extracurricular aircraft class, and I got the okay to take some old painted sheet aluminum for another project I'm working on. The problem is, what I'm using it for I need bare aluminum. I heard around that air crafts are painted with something that regular (store-bought) paint stripper can't remove. Is this true? I am aware of the fact that stripping something like that will result in a toxic paint sludge, so I've taken precautions for that. I just need to know if heavy-duty paint stripper from Home Depot will do the job. Thanks :)

- Go to an automotive paint store like Sherwin Williams Auto Paints, buy a stripper for the type of paint on the aluminum. Many are epoxy or special acrylics like acry glo or jet glo paints and home paint strippers usually won't phase those paints. A methylene chloride mixed with a soap or wax carrier will work but is a hazmat item and has to be disposed of properly but it won't be corrosive to the aluminum. Dupont, Sherwin Williams, and others make the proper strippers. You might even find some at an RV or Boat supply.

- Q: For an intake manifold on a car, as far as increasing the inlet air temperature which is better steel or aluminum? Assuming the cylinder heads are aluminum, and half the thickness of steel is used versus aluminum. I know that steel has a lower heat capacity than aluminum, so does this mean even in this case the steel will heat up quicker and disperse the heat into the inlet air more than aluminum? Basically which material will keep the inlet air as low as possible. I know certain plastics are better than both, but I'm just curious about these two metals. Thank you.

- Increasing heat temperature (Highest point) must be less than melting point of the Aluminum (1221 degree Fahrenheit).Now factor of the weight and stabilizing is important to choose the metal in that section .Aluminum is like fire cricket during melting and if be in flounce of the over heating my cause lot of damages .

- Q: What are the standard widths of aluminum coils?

- The standard widths of aluminum coils vary depending on the industry and application, but common widths range from 12 inches to 60 inches.

- Q: What is the weight of an average aluminum coil?

- The weight of an average aluminum coil can vary depending on its size and thickness. However, as a general estimate, a standard aluminum coil with a thickness of 0.5mm to 1.5mm typically weighs around 1 to 3 tons. It is important to note that this is just an approximation and the actual weight can be higher or lower depending on the specific dimensions and properties of the coil.

- Q: if the resistivity of aluminium is 2.7×10-8 Ωm

- Let ρ be the resistivity of the aluminum cable, A the cross sectional area of the cable and l the cable's length. The resistance R of the aluminum cable is now given by: R = ρ·l / A = 2.7·10^-8·(10·10^3) / (π·r?) = 2.7·10^-8·(10·10^3) / (π·(1·10^-3)?) = 85.9 Ω I guess the tricky part is remembering: R = ρ·l / A but when you realize how intuitive this equation is you don't have to memorize it. The resistance R is proportional to the resistivity ρ, so we must have the following in our equation: R = ρ·k , where k is some value governed by the dimensions of the cable! It is logical that the resistance is also proportional to the wires length l. This is logical when you realize that the longer the wire the more obstacles the electrons will have to pass by! Now we have that: R = ρ·l·c , where c is another value governed now by the cross sectional area (only dimensional property left). If we think of the wire as a highway with cars instead of electrons we realize that there is less resistance (higher speed) when the highway has many lanes and is very broad. From this we realize that the greater the cross sectional area the smaller the resistance. R must therefore be inversely proportional to A. We now have: R = ρ·l / A I hope there are no mistakes here :P

- Q: Hello, I'd like to ask you a question. Can the aluminum coil be continuously pressed and cooled by kerosene?

- Yes, water and oil are not miscible. They must be emulsified

- Q: Are aluminum coils suitable for signage and advertising applications?

- Yes, aluminum coils are suitable for signage and advertising applications. Aluminum is a highly versatile material that offers several advantages for these purposes. First, aluminum is lightweight, making it easy to handle and install. This is especially beneficial for large-scale signage or advertising displays. Second, aluminum is highly durable and resistant to corrosion, ensuring that the signage or advertising materials will withstand the elements and maintain their appearance over time. Additionally, aluminum can be easily fabricated and customized to meet specific design requirements, allowing for creativity and flexibility in signage and advertising applications. Moreover, aluminum is a sustainable material that is recyclable, making it an environmentally friendly choice for signage and advertising projects. Overall, the characteristics of aluminum coils make them an ideal option for signage and advertising applications.

- Q: Is it possible to use a saw to cut aluminum coils?

- <p>Yes, aluminum coils can be cut with a saw, but it's important to use the right type of saw. A hacksaw or a fine-toothed metal cutting saw is suitable for cutting aluminum. Lubrication is also crucial to reduce friction and prevent the saw blade from overheating. When cutting aluminum, it's advisable to use a cutting fluid or a light machine oil to keep the blade cool and ensure a clean, smooth cut. Always follow safety precautions and wear appropriate protective gear when cutting metal.</p>

Send your message to us

HVAC Aluminum Coils - Alloy 1050, 1100, 3003 Mill Finish Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords