Menards Aluminum Coil - Color Coated Brushed Aluminum Coils 2mm - 4mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coated Brushed Aluminum Coils 2mm - 4mm

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Color Coated Brushed Aluminum Coils 2mm - 4mm

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Brushed Aluminum Coils 2mm - 4mm

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

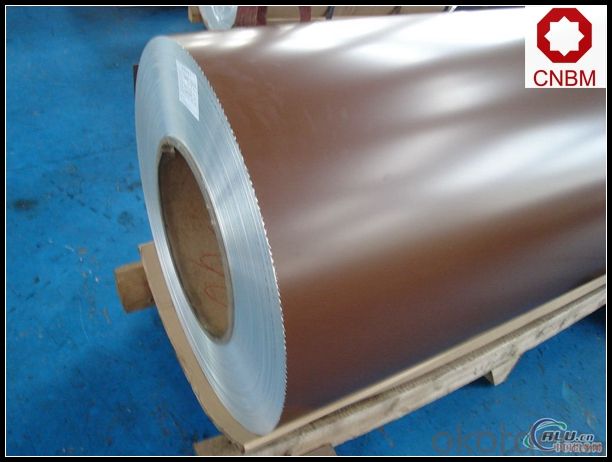

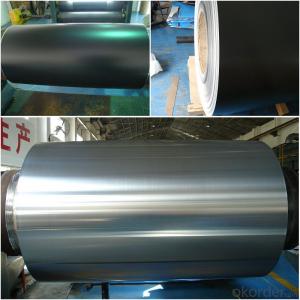

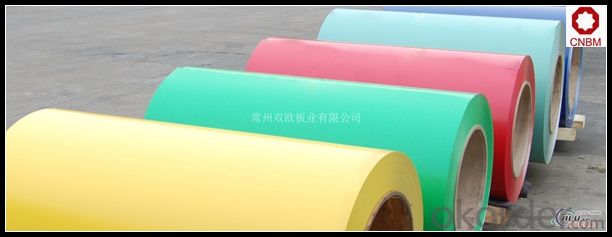

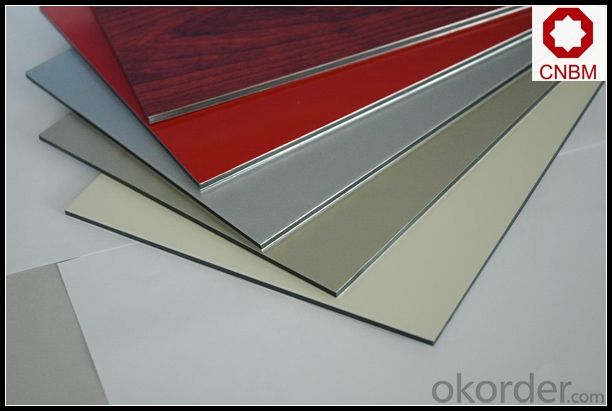

5. Image of Color Coated Brushed Aluminum Coils 2mm - 4mm

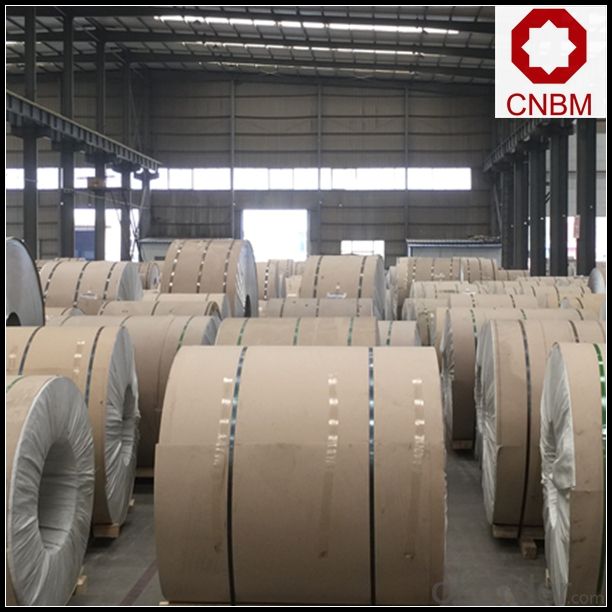

6. Package and shipping of Color Coated Brushed Aluminum Coils 2mm - 4mm

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in the production of heat exchanger fins?

- Yes, aluminum coils can be used in the production of heat exchanger fins. Aluminum is a popular choice for heat exchanger fins due to its high thermal conductivity, lightweight nature, and corrosion resistance. These properties make it an ideal material for transferring heat efficiently while also ensuring durability and longevity. Aluminum coils can be easily formed into intricate fin shapes, maximizing the surface area for heat exchange. Additionally, aluminum is readily available and cost-effective, making it a preferred choice for heat exchanger fin production in various industries such as HVAC, automotive, and refrigeration.

- Q: How are aluminum coils used in the production of solar panels?

- Aluminum coils play a crucial role in the production of solar panels. These coils are typically used in the construction of the photovoltaic (PV) module, which is the core component responsible for converting sunlight into electricity. Firstly, aluminum coils are used as the primary material for the frame of the PV module. The frame provides structural support and protection to the delicate solar cells, ensuring they are secure and safe from external factors such as weather conditions or physical damage. Aluminum's lightweight yet sturdy nature makes it an ideal choice for this purpose, as it offers durability without adding excessive weight to the overall structure. Secondly, aluminum coils are often used as the backsheet material in solar panels. The backsheet is a critical component that protects the solar cells from moisture, dust, and other environmental elements. It acts as a barrier, preventing any potential damage to the cells while also providing electrical insulation. Aluminum's excellent corrosion resistance and electrical conductivity make it an ideal material for this application. Furthermore, aluminum coils are used in the production of the interconnection system within the solar panel. This system consists of conducting wires that connect the individual solar cells, allowing the flow of electricity between them. Aluminum's high electrical conductivity ensures efficient transmission of the generated electricity, minimizing energy losses within the panel. In addition to these key roles, aluminum coils are also used in the manufacturing of various other components within solar panels, such as junction boxes, connectors, and mounting systems. These components contribute to the overall functionality and reliability of the solar panel. Overall, aluminum coils are extensively utilized in the production of solar panels due to their lightweight, durable, and corrosion-resistant properties. Their versatility and ability to withstand harsh environmental conditions make them an essential material for ensuring the longevity and efficiency of solar panel systems.

- Q: This question asks about the environmental friendliness of aluminum coils.

- <p>Aluminum coils are considered environmentally friendly for several reasons. They are highly recyclable, with the recycling process requiring significantly less energy compared to producing new aluminum. This reduces greenhouse gas emissions and conserves resources. Additionally, aluminum is a non-toxic material that does not leach harmful substances into the environment. However, the environmental impact also depends on the production process, which can consume energy and generate emissions. Overall, when properly recycled, aluminum coils have a lower environmental footprint than many other materials.</p>

- Q: Can aluminum coils be used for thermal insulation purposes?

- No, aluminum coils cannot be used for thermal insulation purposes. Aluminum is a highly conductive metal, meaning it easily transfers heat. Therefore, using aluminum coils as thermal insulation would actually promote heat transfer rather than preventing it. For effective thermal insulation, materials with low thermal conductivity, such as fiberglass, foam, or mineral wool, are commonly used. These materials create a barrier that limits heat transfer, keeping the desired temperature within a space.

- Q: What are some normal everyday products made from aluminum that I can use to recycle?

- Soda cans. Beer cans. Pie tins. Aluminum foil. Traffic signs. A few components of some automobiles like the hood (bonnet) and the cylinder heads for some engines. Airplanes - most all the structure metal and all the skins in all but the newest composite (fiberglass) planes. Aluminum recycling uses so much less energy than refining from bauxite ore that a high percentage of aluminum gets recycled.

- Q: Can aluminum coils be used in refrigeration systems?

- Yes, aluminum coils can be used in refrigeration systems. Aluminum is a common material choice for evaporator coils in refrigeration systems due to its excellent heat transfer properties, corrosion resistance, and lightweight nature.

- Q: How many companies have used aluminum coil?

- Too many. All the companies who make the aluminum products you have seen in daily life have used it. So it is hard to explain.

- Q: Should the aluminum roll be in the direction of the aluminum roll length or width?

- Grade two subgrade width is 10.0m. When setting up the slow lane, the width of the new standard subgrade is 15m and 12m respectively, while the original standard is 17.0m, corresponding lane 14.0m.Provincial standard is 20m, but must be hard shoulder, the corresponding pavement width of 10.5m, 8.5m.The highway bridge, a special highway, using integrated superstructure, median and shoulder width of appropriate narrow, but should not be less than the minimum value of the corresponding standard 28m subgrade, bridge deck width is 26m.

- Q: Can aluminum coils be used in corrosive environments?

- Certainly, aluminum coils are suitable for use in environments that are prone to corrosion. The reason behind this lies in the remarkable corrosion resistance of aluminum, which is attributed to the development of a shielding oxide layer on its surface. This oxide layer effectively acts as a barricade, thwarting any future corrosion. Furthermore, manufacturers often apply an additional protective coating or employ specialized treatments to augment the resilience of aluminum coils against corrosive environments. Nevertheless, it is imperative to thoroughly evaluate the exact corrosive conditions and seek advice from experts to ensure the compatibility of the chosen aluminum coil and protective measures with the specific circumstances in which they will be employed.

- Q: Are aluminum coils suitable for decorative purposes?

- Yes, aluminum coils are suitable for decorative purposes. Aluminum is a versatile material that can be easily molded into various shapes and sizes, making it suitable for decorative applications. Its lightweight nature, durability, and resistance to corrosion make it an ideal choice for both indoor and outdoor decorative projects. Additionally, aluminum can be finished with different coatings and finishes, such as powder coating or anodizing, to enhance its aesthetic appeal. These coatings can provide a wide range of colors, textures, and patterns, allowing for endless design possibilities. Furthermore, aluminum coils can be easily formed into intricate designs, making them suitable for decorative elements like trims, accents, panels, or even sculptures. Overall, aluminum coils offer a cost-effective, durable, and aesthetically pleasing option for various decorative purposes.

Send your message to us

Menards Aluminum Coil - Color Coated Brushed Aluminum Coils 2mm - 4mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords