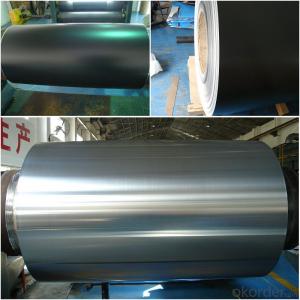

Coating Aluminum Coils - Alu Roll, Mill Finish and Coated

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Specification:

Alloy: AA1050, 1060, 1100,AA3003, 3005, 3015, 5052, 5754, 5083,8011, etc

Temper: H14/16/18/22/24/32,HO etc.

Thickness: 0.2mm—100mm

Width: 100mm—2300mm (Can be slitted)

Inner Diameter:508MM

Coil Weight:500kg-3000kg(Max.)

Application:Foil stock, Circles, Roofing, Can stock, Marine plate,Anti-slipery purpose in vehicles, packing and appliance.

Features:

1. Excellent quality of products

2. Quick delivery

3. Best service to clients

4. BV,SGS avalible

5. No buckle o waveness

6. Tension leveling

7. Certificate of Origin

8. Form A,E

Packaging Detail:

Carton ,Woodenpallet with plastic protection packing ,standard seaworthy packing or as yourrequest.

Production Capacity:

AnnualProduction capacity of 600,000 tons.

Products areexported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam,Nigeria etc, over 100 countries andregions all over the world.

Production Line:

CNBM aluminumproduction base is comprised of 18 aluminumannealers, 10 coil and foilmills, 4 continuous production lines, 2hot rolling production line and 3prepainted lines.

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shanghai port

4. Delivery time?

30 days after client’s deposit

- Q: Are there any restrictions on the coil surface quality of aluminum coils?

- Yes, there are restrictions on the coil surface quality of aluminum coils. The surface quality of aluminum coils is important for various applications, including aesthetics and functionality. Common restrictions include limitations on surface defects such as scratches, pits, and stains, as well as restrictions on the presence of oil, grease, or other contaminants. These restrictions ensure that the aluminum coils meet the required quality standards and can be used effectively in different industries.

- Q: Can aluminum coils be used in heat exchanger fins?

- Yes, aluminum coils can be used in heat exchanger fins. Aluminum is a common material choice for heat exchangers due to its excellent thermal conductivity and corrosion resistance. Aluminum coils can efficiently transfer heat and withstand high temperatures, making them suitable for use in heat exchanger fins.

- Q: I was at an art festival and saw one of the most unique displays ever. The artist had painted abstract art on a piece of aluminum (or some type of aluminum type sheeting) I, being a novice artist for many years, was very intrigued and would LOVE to learn more about it. I've done searches on the internet, to no avail. Anyone have any ideas?

- I've known a couple of people who do this, you might try a search on Floating Panel. You could try to search out things on an artist called Gary Hume, as I know that his earlier paintings, certainly the ones for which he's known, were executed on aluminium. From what I remember of people doing this (some one on my MA made paintings on aluminium) the trick is in the priming, it being a non-pours surface. You need to rough the ground considerably and prime quite thickly. You also need to baton on the back, this will allow you to attach to the wall without ruining the face of the support, and prevent the possibility of warping. What looks great is if you recess the batons from the edge of the support, so that when against the wall they cannot be seen, this gives the appearance of hovering, and shows the thinness of your support. Another reason you might not be getting too many hits on your searches is the spelling, while not incorrect you might find art suppliers using the English, rather than the American spelling; aluminium rather than aluminum. I know that sounds petty but it might make a difference. The only other thing I know, while finding it a great surface to work on, smooth, bright, the artist I know also found it very expensive.

- Q: This question asks for a comparison between single-coil and multi-coil aluminum tubes, highlighting their differences.

- <p>Single-coil aluminum tubes are made with a single layer of aluminum wound into a cylindrical shape, offering simplicity and ease of manufacturing. They are typically used in applications requiring basic heat exchange or formwork. In contrast, multi-coil aluminum tubes consist of multiple layers of aluminum wound together, which can provide greater strength and durability. They are often utilized in more demanding applications where higher pressure resistance and thermal efficiency are required, such as in high-performance heat exchangers or industrial processes. The multi-coil design also allows for better heat distribution and can handle more stress without deformation.</p>

- Q: How do aluminum coils contribute to noise reduction?

- There are multiple ways in which aluminum coils contribute to reducing noise. Firstly, aluminum, being a lightweight material, can effectively absorb and dampen sound waves. When utilized in coils, it aids in decreasing vibrations and minimizing the transmission of noise. Furthermore, aluminum possesses excellent thermal conductivity properties, which aid in dissipating heat and preventing temperature-related noises. This is particularly crucial in HVAC systems, where the noise generated by the equipment can be substantial. Moreover, aluminum coils can be designed with special features like grooves or fins that enhance their noise reduction capabilities. These features serve to increase the coil's surface area, facilitating better heat transfer and reducing noise levels. In general, aluminum coils offer an efficient and effective solution for noise reduction in a wide range of applications, making them a favored choice in industries where noise control is of utmost importance.

- Q: Are aluminum coils suitable for beverage can manufacturing?

- Yes, aluminum coils are suitable for beverage can manufacturing.

- Q: ... of aluminum atoms?(mole = 6.022x10^23)

- WHEN IM OUT ON THE SEA WITH ME CREW I LIKE TO THINK THAT PERHAPSY WE CAN LOOT A BARGE FULL 'O THAT WONDROUS MATERIAL YE CALL ALUMINUM AS FER MOLES, THEY CAN BE QUITE THE PESTS AROUND YER GARDEN AND WHAT-NOT

- Q: This question asks about the impact of aluminum coils on the quality of welding. It seeks to understand the relationship between the material properties of aluminum coils and the outcomes of the welding process.

- <p>Aluminum coils can significantly affect welding quality due to their unique properties. Aluminum has a high thermal conductivity, which requires more energy to weld, and can lead to rapid heat dissipation, affecting the weld's uniformity. Oxides on the aluminum surface can also interfere with the welding process, causing porosity and poor joint strength if not properly cleaned. Additionally, aluminum's low melting point can lead to distortion and warping if not managed correctly. The use of appropriate filler materials, proper cleaning, and precise control of welding parameters are crucial to achieve high-quality welds with aluminum coils.</p>

- Q: What rules or laws govern the transportation of old or damaged aluminum coils?

- <p>Yes, there are regulations on the transportation of old or damaged aluminum coils. These regulations often fall under hazardous materials or waste transportation laws, depending on the condition of the coils. In the United States, the Department of Transportation (DOT) regulates the transportation of hazardous materials, which may include damaged aluminum coils if they pose a risk. The Environmental Protection Agency (EPA) also has guidelines for the transportation of waste materials. Internationally, the International Maritime Dangerous Goods (IMDG) Code and International Air Transport Association (IATA) Dangerous Goods Regulations provide guidance for the safe transport of such materials. Compliance with packaging, labeling, documentation, and handling requirements is crucial to ensure safety and avoid penalties.</p>

- Q: Aluminum coil thickness measurement, real-time measurement of aluminum coil thickness value, you can use displacement sensor?

- Yes, the two sensors measure and measure the thickness

Send your message to us

Coating Aluminum Coils - Alu Roll, Mill Finish and Coated

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords