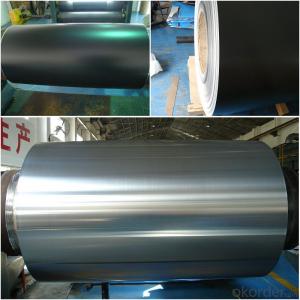

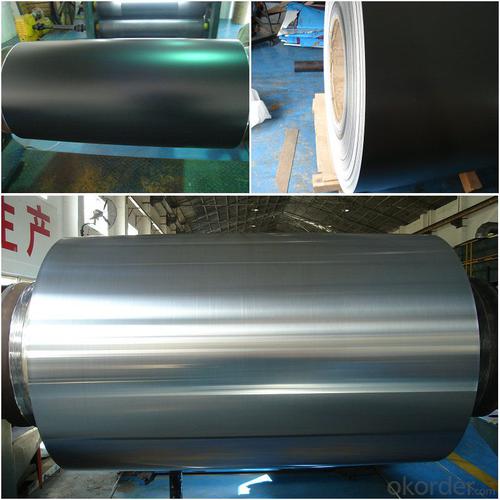

Menards Aluminum Coil - Black Color Coated Mill Finish Aluminum Rolls

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Color coated aluminum coil is a material with excellent acid-resistance and alkali-resistance. The coating layeris even with bright color to last for a very long time. It is a greendecoration material with the characters of environment protection,flame-resistance, and groovy colors. In nowadays, the color coatedaluminum coil has become the popular material for top grade decoration. With our advance professional aluminum coated technique, wecan custom various aluminum coils ,like coated aluminum coil , Color coatedaluminum coil , embossed aluminum sheet with the color and size which youdemands.

1)Process: pre-treatment, continuous painting and baking for times .

2)Material: high quality material, aluminum sheets from South West AluminumIndustry Company in China, pre-treatment material from Henkel & Chemtellfrom Germany, more than 70% of PVDF coating from PPG Corp., the USA andpolyester from Sweden Becker Industrial Coating Co., Ltd.

3) Ourproducts can keep excellent quality and stability.

4)Thickness: 0.06 - 1.0mm; width: 20 - 1,590mm

Applications:

The aluminum coils are widely used in ACP/curtainpanel/honey comb panel/shutter/roofing and most of the decoration areas. Withthe superior quality and advanced management, our products had been export toEuro/North America /East Asia and many other areas and countries.

PEAluminum Coating Coils for ACP

Featuresof PE Aluminum Sheet:

1.Adopting precision rolling coating technology, our PVDF and PE coated coil canensure excellent adhesive without coating omission.

2. For thePE coated aluminum coil we produced, there are various colors for your choice.

3. Usinginfrared heating technology to protect environment from pollution.

4. Ourcoated aluminum coil has four-roller coating line, uniform coating thicknessand good features.

RawMaterial of the PE Aluminum Coating Coils:

1. Aluminum Coil: high strength aluminum withalloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005according to customer)

2. Surface Paint: PE, PVDF and specialpaints.

Specification of PE Aluminum Coating Coil

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

PE coated aluminum coil is processed throughthe technics of roller coating and baking with precise polyester paints. Itscolor is glossy and with variety of colors enabling you to choose easily.Chromatic aberration is small, impact resistance is strong and easy to beprocessed, and all its performance has reached or surpassed the nationalcriteria. The products are widely used in indoor and door decoration, ceilings,room surface tiles, corrugated boards, wallpanels, advertisement boards, counters, home appliances, decoration in and outof autos and boats.

Performance of thecoating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Color of Card

PE (polyester)

PE

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q: like i need a good slogan for aluminum its for a school project like for arsenic's is Arsenic's a sure fire way to deal with a rat, It works better than a mean old cat!

- Aluminium's the stuff in bicycles, And cans and planes and recyclables! Hope you liked that! 3, phantasmal.spirit

- Q: im looking for a bat but i dont know what to get wood or aluminum what is harder wood or aluminum ?? what would be better for hitting hard balls with ( or maybe people ) haha no im joking i need help !!!!

- Aluminum. When you hit the ball, it goes farther then a wooden bat. That is why MLB players can't use them, just in case of a line drive to the pitcher. They have enough problems dodging it, and this would get a lot more of them hit.

- Q: Are aluminum coils suitable for corrosion-resistant applications?

- Aluminum coils are highly suitable for applications requiring resistance to corrosion. This is because aluminum naturally develops a protective oxide layer on its surface, offering excellent defense against corrosion caused by moisture, chemicals, and environmental elements. Furthermore, aluminum's corrosion resistance can be further augmented through the application of diverse coatings and treatments. Consequently, aluminum coils find widespread use in critical areas where corrosion resistance is paramount, such as the construction industry, automotive sector, and marine applications.

- Q: Can aluminum coils be used in transformer windings?

- Yes, aluminum coils can be used in transformer windings. Aluminum is a commonly used material for transformer windings due to its low resistivity, high conductivity, and cost-effectiveness compared to copper. It offers several advantages such as lighter weight, better thermal conductivity, and lower manufacturing cost. However, there are some considerations when using aluminum coils in transformer windings, such as the need for larger cross-sectional area to compensate for its lower conductivity compared to copper. Additionally, special techniques may be required to prevent galvanic corrosion when aluminum is in contact with other metals in the transformer. Overall, aluminum coils can be a suitable alternative to copper coils in transformer windings, offering benefits in terms of efficiency and cost.

- Q: What is the balanced chemical equation for aluminum and cobalt?That is all the information that the question gives. If you could help me out, I would really, really appreciate it.

- That's pretty sparse. Perhaps the question is referring to a single replacement reaction. Aluminum is above cobalt in the activity series, which allows us to predict that aluminum metal will reduce cobalt ions, while aluminum is oxidized. This occurs as long as there is an ion present which will react with the aluminum oxide layer on the surface of aluminum. This passivating Al2O3 layer keeps aluminum metal from reacting. The presence of chloride ions will break down the passivating layer allowing the aluminum metal below to react. Al2O3(s) + 6H+ + 8Cl- -- 2[AlCl4]- + 3H2O(l) 2Al(s) + 3Co2+ -- 2Al3+ + 3Co(s)

- Q: How much cube is the 0.9mm aluminum rolling?

- This is a common problem. Anyone who had received high school education can calculate it very quickily. One way is to calculate sectional area with circular area, then times the thickness of the aluminum rolling. Another way is to use the outer diameter circular area to subtract the core area and then times the thickness of aluminum rolling.

- Q: Are aluminum coils easy to install?

- Aluminum coils, in general, prove to be easily installed. Their lightweight and flexibility contribute to their manageable handling and maneuverability during installation. They can be effortlessly cut and molded to suit the precise installation requirements. Moreover, they are frequently obtainable in pre-cut dimensions, further streamlining the installation procedure. Additionally, aluminum coils usually incorporate interlocking edges or snap-on connectors, facilitating the connection of multiple coils or other components. All in all, with appropriate tools and fundamental HVAC installation knowledge, aluminum coils can be readily installed.

- Q: How are aluminum coils typically stored and transported?

- Aluminum coils, in order to safeguard them and avoid any harm, are typically stored and transported in a manner that guarantees their protection. They are commonly stored in a warehouse or storage facility, maintaining a vertical position to prevent any bending or warping. Regarding transportation, specialized coil trailers or flatbed trucks are often utilized to transport aluminum coils. These trailers are designed specifically to securely hold the coils in place during transit. Straps or bands are typically employed to fasten the coils tightly, preventing any movement or shifting while on the road. Furthermore, it is customary for aluminum coils to be enveloped in protective materials such as plastic or cardboard during transportation. This extra layer of protection serves to shield the coils from moisture, dirt, and other potential hazards. It is of utmost importance to handle aluminum coils with caution to avoid any damage, as even minor dents or scratches can impact their performance. Hence, employing appropriate storage and transportation methods is vital to ensure that the coils reach their destination in optimal condition.

- Q: How do aluminum coils perform in corrosive environments?

- Aluminum coils perform exceptionally well in corrosive environments due to their natural resistance to corrosion. The formation of a thin, protective oxide layer on the surface of aluminum coils helps prevent further corrosion from occurring. This property makes them highly suitable for applications exposed to moisture, chemicals, and other corrosive agents.

- Q: What are the different surface finishes for pre-painted aluminum coils?

- The different surface finishes for pre-painted aluminum coils include smooth, textured, embossed, brushed, and metallic finishes.

Send your message to us

Menards Aluminum Coil - Black Color Coated Mill Finish Aluminum Rolls

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords