Melt Extract Stainless Steel Fiber - Straight Type from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

1. Material: low carbon steel wire or stainless steel

2.Diameter: 0.4mm-1.0mm

3.Length: meet your requirements

4.tensile strength >1000Mpa

6.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

7.Uses: highway road surface,tunnel,building,airport road surface and so on .

Straight Steel Fiber

1.ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

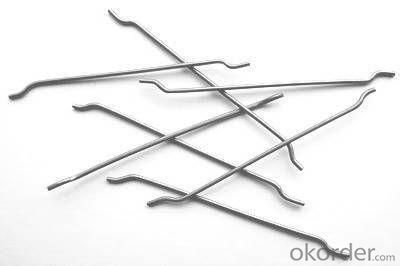

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: What is the effect of melt extract stainless steel fiber on the crack width in concrete?

- The use of melt extract stainless steel fibers in concrete has a significant effect on the crack width. These fibers are added to the concrete mixture to enhance its durability and strength. When the concrete is subjected to external forces or temperature fluctuations, cracks may occur. However, the presence of stainless steel fibers helps to control and minimize the width of these cracks. The main reason behind this effect is the unique properties of stainless steel fibers. These fibers are known for their high tensile strength and ductility. When cracks start to form in the concrete, the stainless steel fibers act as reinforcement and distribute the stress across the matrix. This redistribution of stress helps to prevent the cracks from widening. Additionally, the presence of stainless steel fibers also improves the overall toughness of the concrete. As a result, the concrete becomes more resistant to crack propagation. This means that even if cracks do form, they are less likely to extend and cause significant damage. Moreover, melt extract stainless steel fibers also improve the overall durability of the concrete. They act as a barrier against corrosion, protecting the concrete from the harmful effects of moisture, chemicals, and other environmental factors. This enhances the lifespan of the concrete structure and reduces the need for frequent repairs or replacements. In summary, the use of melt extract stainless steel fibers in concrete has a positive effect on the crack width. These fibers reinforce the concrete matrix, distribute stress, and prevent cracks from widening. Furthermore, they improve the overall toughness and durability of the concrete, making it more resistant to crack propagation and extending its lifespan.

- Q: Can melt extract stainless steel fiber enhance the resistance of concrete to acid attack?

- Yes, melt extract stainless steel fiber can enhance the resistance of concrete to acid attack. Stainless steel fibers are known for their high corrosion resistance and durability. When added to concrete, they form a network that improves the strength and performance of the material. In the case of acid attack, concrete is prone to deterioration and damage. Acids can react with the calcium hydroxide in the cement paste, leading to the dissolution of the concrete matrix and a decrease in its strength. However, when stainless steel fibers are incorporated into the concrete mix, they create a barrier that prevents the acid from directly contacting the cement paste. The stainless steel fibers act as a reinforcement, enhancing the mechanical properties of the concrete. They provide additional strength and toughness, making the concrete more resistant to acid attack. The fibers also help in distributing the stress and reducing crack formation, further protecting the concrete from acid penetration. Additionally, the corrosion resistance of stainless steel fibers ensures that they remain intact even in aggressive environments. This means that they can continue to provide reinforcement and protection to the concrete for an extended period. Overall, melt extract stainless steel fiber can significantly enhance the resistance of concrete to acid attack by reinforcing the material, preventing direct contact between acids and the cement paste, and improving the durability of the concrete.

- Q: What is the effect of melt extract stainless steel fiber on the workability of shotcrete?

- The use of melt extract stainless steel fiber in shotcrete improves its workability by enhancing the mix's cohesion and reducing the occurrence of segregation. This results in improved pumpability and reduced rebound, making the shotcrete easier to handle and apply. Additionally, the steel fibers enhance the overall strength and durability of the shotcrete, providing added reinforcement against cracking and shrinkage.

- Q: What are the applications of melt extract stainless steel fiber?

- Melt extract stainless steel fibers have various applications in different industries. They are commonly used in concrete reinforcement to enhance the durability and strength of structures like bridges and pavements. These fibers also find application in high-temperature insulation materials, as they can withstand extreme temperatures and provide thermal resistance. Additionally, melt extract stainless steel fibers are used in the production of friction materials, such as brake pads, to improve their wear resistance and performance. Overall, these fibers offer excellent mechanical properties, corrosion resistance, and thermal stability, making them suitable for a wide range of applications.

- Q: What is the effect of melt extract stainless steel fiber on the early-age cracking of concrete?

- Reducing early-age cracking in concrete can be achieved through the utilization of melt extract stainless steel fiber. There are various factors that contribute to early-age cracking, including temperature fluctuations, shrinkage, and rapid moisture loss. By incorporating stainless steel fibers into the concrete mixture, the overall tensile strength of the material is enhanced, providing reinforcement. This reinforcement plays a crucial role in controlling the formation and propagation of cracks during the initial stages of concrete curing. The exceptional properties of melt extract stainless steel fibers, such as their high tensile strength, resistance to corrosion, and durability, make them an ideal choice for mitigating early-age cracking. These fibers effectively disperse stress throughout the concrete matrix, restricting the initiation and spread of cracks. Furthermore, melt extract stainless steel fibers can also aid in managing plastic shrinkage cracking. During the early stages of concrete curing, rapid loss of moisture can cause the surface to shrink and crack. By incorporating stainless steel fibers, this shrinkage is restrained, thereby reducing the likelihood of early-age cracking. It is worth noting that the precise impact of melt extract stainless steel fiber on early-age cracking may vary depending on factors such as the dosage of fibers, the design of the concrete mix, and environmental conditions. Therefore, comprehensive testing and consultation with experts are essential to determine the optimal dosage and application of fibers for a specific project.

- Q: Steel fiber prices? (recent price)

- Shear type steel fiber according to material pricing is divided into 2; 1 kinds of scrap to do the general price at 5200-5400 yuan / ton.The 2 is made of whole material, the average price is 8000-84000 yuan / ton.

- Q: How does melt extract stainless steel fiber improve the ductility of shotcrete?

- Melt extract stainless steel fiber improves the ductility of shotcrete by enhancing its ability to withstand deformation and cracking. The addition of stainless steel fibers to the shotcrete mix creates a reinforced matrix that provides increased tensile strength and flexural capacity. When shotcrete is applied, it undergoes a curing process where it hardens and gains strength. However, without any reinforcement, shotcrete is prone to cracking under tensile stresses. By incorporating melt extract stainless steel fibers, the shotcrete gains improved ductility as the fibers distribute the tensile forces throughout the material, preventing the formation and propagation of cracks. The unique properties of stainless steel, such as its high tensile strength and corrosion resistance, make it an ideal material for reinforcing shotcrete. The fibers are uniformly dispersed within the shotcrete mix, providing a three-dimensional reinforcement system that enhances its structural integrity. The addition of stainless steel fibers also improves the overall durability of shotcrete. The fibers act as a barrier to prevent the penetration of water and other harmful substances, reducing the risk of corrosion and deterioration. This ensures a longer service life and minimizes the need for costly maintenance and repairs. In summary, melt extract stainless steel fiber improves the ductility of shotcrete by reinforcing its structure and enhancing its ability to withstand tensile stresses and deformation. By incorporating these fibers, shotcrete gains increased strength, durability, and resistance to cracking, ultimately improving its performance and extending its lifespan.

- Q: Can melt extract stainless steel fiber be used in the construction of dams?

- Yes, melt extract stainless steel fiber can be used in the construction of dams. It is commonly used as a reinforcing material in concrete to enhance its strength, durability, and resistance to cracking. This makes it suitable for constructing dams, which require high strength and structural integrity to withstand water pressure and other environmental factors.

- Q: How does the addition of melt extract stainless steel fiber affect the toughness of concrete?

- The addition of melt extract stainless steel fiber significantly enhances the toughness of concrete. These fibers act as reinforcement within the concrete matrix, increasing its resistance to cracking and improving its overall durability. The stainless steel fibers help to distribute stress and absorb energy, resulting in a more robust and resilient concrete structure.

- Q: Can melt extract stainless steel fiber be used in wastewater pipeline construction?

- Melt extract stainless steel fiber is a viable option for constructing wastewater pipelines. Thanks to its remarkable corrosion resistance, it is an appropriate material for such pipelines, which often encounter corrosive chemicals and substances. Furthermore, its durability and high tensile strength allow it to withstand the pressure and stress imposed on pipelines. In addition, the low thermal expansion properties of stainless steel fiber aid in averting warping or distortion caused by temperature fluctuations. Ultimately, incorporating melt extract stainless steel fiber into wastewater pipeline construction enhances the longevity and dependability of the pipeline system.

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords