Melt Extract Stainless Steel Fiber - Straight Type from CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

Micro steel fiber:

1.Material: low carbon steel wire,copper coated

Diameter:0.2mm --0.25mm

Length: 12mm-14mm

Tensile strength:>2850Mpa

2.Feature:Excellent tensile, bending and shearing strength, resistance against cracking, impact and fatigue.

3.Use:It is widely used for buildings, road surface, bridges, tunnels, airport road surface, water conservancy projects, military engineering, and all kinds of building products.

Specifications

1.Material: low carbon steel wire

2.Diameter: 0.2mm --0.25mm

3.Length: 12mm-14mm

4. ISO 9001 certificated

Hooked steel fiber:

1.Diameter:0.4mm-1.0mm

2.Length: 25mm-60mm

3.Material: low carbon steel wire

4.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

5.Uses: highway road surface,tunnel,building,airport road surface and so on .

Micro steel fiber:

1.Material: low carbon steel wire,copper coated

Diameter:0.2mm --0.25mm

Length: 12mm-14mm

Tensile strength:>2850Mpa

2.Feature:Excellent tensile, bending and shearing strength, resistance against cracking, impact and fatigue.

3.Use:It is widely used for buildings, road surface, bridges, tunnels, airport road surface, water conservancy projects, military engineering, and all kinds of building products.

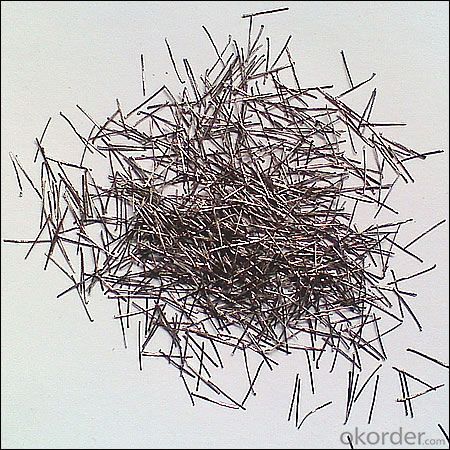

Picture

Steel fiber straight type

FAQ

Straight steel fiber:

1) Material: low carbon steel wire

2) Diameter: 0.4mm

3) Length: 18mm-35mm

4) Tensile strength: >1000Mpa

5) Feature: excellent tensile, high tenacity, against cracking, impact and fatigue

6) Uses: highway road surface, tunnel, building, airport road surface and so on.

- Q: How does melt extract stainless steel fiber improve the toughness of fiber-reinforced shotcrete?

- Melt extract stainless steel fiber improves the toughness of fiber-reinforced shotcrete by providing enhanced crack resistance and increased ductility. The inclusion of these fibers in shotcrete helps to distribute and dissipate energy upon impact, reducing the propagation of cracks and enhancing the overall strength and durability of the material.

- Q: How does melt extract stainless steel fiber improve the freeze-thaw resistance of concrete?

- Melt extract stainless steel fiber is an innovative material that greatly enhances the freeze-thaw resistance of concrete. This type of fiber is derived from stainless steel through a specialized extraction process, which ensures its purity and high-quality characteristics. The freeze-thaw resistance of concrete refers to its ability to withstand the repeated cycles of freezing and thawing that occur in cold weather conditions. When water trapped within the concrete freezes, it expands, exerting pressure on the surrounding material. This pressure can cause cracks, spalling, and other forms of deterioration in the concrete structure over time. By incorporating melt extract stainless steel fibers into the concrete mix, several mechanisms come into play to improve its freeze-thaw resistance. Firstly, the fibers act as reinforcement within the concrete matrix, providing additional tensile strength and reducing the formation and propagation of cracks. This helps to maintain the overall structural integrity of the concrete, even when subjected to freeze-thaw cycles. Moreover, the stainless steel composition of these fibers offers excellent corrosion resistance. Concrete is often exposed to various environmental factors, including the presence of chloride ions from de-icing salts, which can accelerate the corrosion process. However, the stainless steel fibers inhibit the corrosion of embedded reinforcing steel, thereby preserving the concrete's durability and freeze-thaw resistance. Additionally, the presence of melt extract stainless steel fibers enhances the overall durability of the concrete. These fibers improve the cohesion and bond between the aggregate and cement paste, resulting in a more dense and impermeable concrete matrix. This reduces the ingress of water and other harmful substances, such as chloride ions, into the concrete, further safeguarding it against freeze-thaw damage. In conclusion, melt extract stainless steel fiber plays a crucial role in enhancing the freeze-thaw resistance of concrete. By providing reinforcement, corrosion resistance, and improved durability, these fibers effectively mitigate the detrimental effects of freeze-thaw cycles on concrete structures, ensuring their longevity and integrity.

- Q: How does melt extract stainless steel fiber improve the toughness of concrete?

- Melt extract stainless steel fiber improves the toughness of concrete by enhancing its crack resistance and durability. The steel fibers act as reinforcement within the concrete matrix, distributing and absorbing stress and preventing the propagation of cracks. This improves the overall strength and longevity of the concrete, making it more resistant to impact, flexural, and fatigue loads.

- Q: What is the effect of melt extract stainless steel fiber on the bond strength of concrete?

- The effect of melt extract stainless steel fiber on the bond strength of concrete is significant. When added to concrete mixtures, stainless steel fibers enhance the bond between the concrete and other materials, improving the overall strength and durability of the structure. Stainless steel fibers act as reinforcement within the concrete matrix, enhancing its tensile strength and preventing crack propagation. These fibers create a three-dimensional network that helps distribute the load and improve the bond between the concrete and other components, such as aggregates or reinforcement bars. The unique properties of melt extract stainless steel fibers, including their high tensile strength, corrosion resistance, and ductility, make them an excellent choice for enhancing the bond strength of concrete. The fibers effectively bridge the gaps between cracks or weak spots in the concrete, preventing further deterioration and increasing the overall structural integrity. In addition to improving bond strength, stainless steel fibers also enhance the concrete's resistance to impact, fatigue, and thermal stresses. This makes them particularly suitable for applications where high-performance concrete is required, such as industrial floors, tunnels, bridges, and pavements. Furthermore, the addition of stainless steel fibers can also improve the concrete's resistance to shrinkage and plastic cracking, reducing the need for control joints and minimizing maintenance requirements. Overall, the incorporation of melt extract stainless steel fiber in concrete mixtures significantly improves the bond strength of the material. This results in a more durable and reliable concrete structure, with enhanced resistance to cracking, impact, and other external forces.

- Q: What is the optimal dosage of melt extract stainless steel fiber in concrete mixes?

- The concrete mix's ideal dosage of melt extract stainless steel fiber can vary depending on various factors, including specific application requirements, desired performance characteristics, and the type of concrete used. Typically, the volume dosage of stainless steel fiber in concrete ranges from 0.5% to 2%. However, it is crucial to perform extensive testing and seek advice from industry professionals to determine the precise dosage required for each project. Using higher dosages of stainless steel fiber can enhance the concrete's mechanical properties, such as flexural strength, toughness, and impact resistance. This is particularly advantageous for applications that demand exceptional durability, such as industrial floors, precast elements, or structures exposed to heavy loads or extreme weather conditions. On the contrary, lower dosages may be suitable for applications that prioritize cost-efficiency or where the concrete's appearance plays a significant role. It is vital to strike a balance between desired performance and project economics. Furthermore, selecting the appropriate length and aspect ratio of stainless steel fibers is crucial for achieving the desired performance. Longer fibers provide better crack control and improved ductility, while shorter fibers may be more effective in reducing shrinkage cracking. To determine the optimal dosage, it is recommended to conduct trial mixes using different fiber dosages and evaluate their performance through tests such as flexural strength, impact resistance, and shrinkage tests. This will help identify the dosage that meets the specific project requirements while considering factors like workability and cost-effectiveness. In conclusion, determining the optimal dosage of melt extract stainless steel fiber in concrete mixes requires a comprehensive evaluation of project requirements, desired performance characteristics, and thorough testing. Seeking guidance from industry experts and conducting extensive trials will ensure the best outcome for each application.

- Q: Can melt extract stainless steel fiber be used in the construction of railway tunnels?

- Yes, melt extract stainless steel fiber can be used in the construction of railway tunnels. Stainless steel fiber is known for its high strength, durability, and resistance to corrosion, which makes it suitable for various construction applications, including railway tunnels. The use of stainless steel fiber in tunnel construction helps to enhance the overall structural integrity and longevity of the tunnels. It can reinforce the concrete used in the tunnel lining, providing increased resistance to cracking and improved load-bearing capacity. Additionally, stainless steel fibers can also offer enhanced fire resistance properties, which is crucial for ensuring the safety of railway tunnels. Therefore, melt extract stainless steel fiber is a suitable material to be used in the construction of railway tunnels.

- Q: Can melt extract stainless steel fiber be used in water treatment plant construction?

- Yes, melt extract stainless steel fiber can be used in water treatment plant construction. Stainless steel fibers have excellent corrosion resistance, high tensile strength, and thermal stability, making them suitable for various applications in water treatment plants. These fibers can be used in the construction of concrete structures such as tanks, pipes, and channels to enhance their durability and resistance to cracking and deterioration caused by exposure to water, chemicals, and other harsh environmental conditions. Additionally, the use of stainless steel fibers can help improve the overall structural integrity of the water treatment plant, ensuring long-term performance and reducing maintenance and repair costs.

- Q: Does melt extract stainless steel fiber improve the resistance to spalling of concrete?

- Yes, melt extract stainless steel fiber does improve the resistance to spalling of concrete. Spalling is the phenomenon where the surface layer of concrete flakes or chips off due to various factors such as freeze-thaw cycles, high temperatures, or chemical attacks. By adding melt extract stainless steel fibers to the concrete mix, the fibers act as reinforcement, providing an additional layer of strength and preventing the concrete from spalling. The stainless steel fibers are dispersed throughout the concrete matrix and enhance its overall tensile strength. When the concrete undergoes stress, such as during freeze-thaw cycles or high temperatures, the fibers help to distribute the forces and prevent cracks from propagating. This reinforcement mechanism significantly reduces the chances of spalling, as the stainless steel fibers act as a barrier to prevent the surface layer from chipping off. Additionally, melt extract stainless steel fibers also improve the durability and longevity of the concrete. The fibers enhance the resistance to corrosion, which is a common cause of spalling in concrete exposed to harsh environments or chemical attacks. By providing a protective layer against corrosion, the stainless steel fibers ensure that the concrete retains its integrity and remains resistant to spalling over an extended period. In conclusion, the addition of melt extract stainless steel fiber to concrete does improve its resistance to spalling. The fibers act as reinforcement, distributing stress and preventing cracks from propagating, while also enhancing the durability and corrosion resistance of the concrete.

- Q: Can melt extract stainless steel fiber be used in high-performance concrete?

- Yes, melt extract stainless steel fiber can indeed be used in high-performance concrete. Stainless steel fibers are commonly used as reinforcement in concrete to enhance its mechanical properties and durability. The melt extract stainless steel fibers are made by melting stainless steel and then drawing it into fine fibers. These fibers are typically added to concrete mixtures in small quantities to improve its tensile strength, flexural strength, and resistance to cracking. The use of melt extract stainless steel fibers in high-performance concrete can significantly enhance its performance. The fibers act as reinforcement, providing additional strength and preventing the propagation of cracks. This is especially important in high-performance concrete, which is designed to have superior mechanical properties and withstand harsh conditions. The addition of melt extract stainless steel fibers can improve the concrete's resistance to impact, fatigue, and fire. It also helps to reduce shrinkage and cracking, thus increasing the service life of the concrete structure. Moreover, stainless steel fibers are corrosion-resistant, which is particularly beneficial in environments where the concrete is exposed to aggressive chemicals or moisture. In conclusion, melt extract stainless steel fiber is a suitable and effective reinforcement material for high-performance concrete. It improves the concrete's mechanical properties, durability, and resistance to cracking, thereby enhancing the overall performance of the concrete structure.

- Q: What is the effect of melt extract stainless steel fiber on the alkali-silica reaction in concrete?

- The effect of melt extract stainless steel fiber on the alkali-silica reaction in concrete is generally positive. The alkali-silica reaction is a chemical reaction that occurs between the alkalis in cement and certain types of reactive silica present in aggregates used in concrete. This reaction can cause significant expansion, cracking, and deterioration of the concrete over time. However, when melt extract stainless steel fibers are added to the concrete mix, they can act as a reinforcement and help mitigate the effects of the alkali-silica reaction. The stainless steel fibers provide additional structural support to the concrete, reducing the potential for cracking and improving the overall durability of the material. The stainless steel fibers also help to control the expansion caused by the alkali-silica reaction by providing a physical barrier that restricts the movement of the reactive silica particles. This helps to prevent the formation of cracks and limit the damage caused by the reaction. In addition, the stainless steel fibers enhance the mechanical properties of the concrete, including its tensile strength, flexural strength, and impact resistance. This can further improve the performance of the concrete in various applications, such as in high-stress environments or in structures where durability is crucial. Overall, the addition of melt extract stainless steel fiber to concrete can effectively reduce the negative effects of the alkali-silica reaction, enhancing the long-term performance and durability of the concrete.

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type from CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords