Melt Extract Stainless Steel Fiber - Straight Type Steel Fiber by CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

1. Material: low carbon steel wire or stainless steel

2.Diameter: 0.4mm-1.0mm

3.Length: meet your requirements

4.tensile strength >1000Mpa

6.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

7.Uses: highway road surface,tunnel,building,airport road surface and so on .

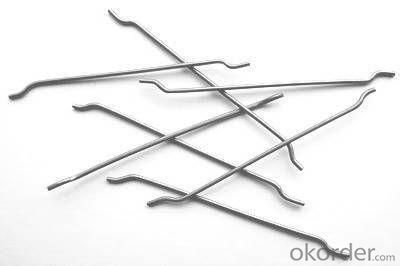

Straight Steel Fiber

1.ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: Does melt extract stainless steel fiber have a high resistance to corrosion?

- Yes, melt extract stainless steel fiber has a high resistance to corrosion. Stainless steel is known for its excellent corrosion resistance due to the presence of chromium in its composition, which forms a protective oxide layer on the surface of the steel. This oxide layer acts as a barrier to prevent the steel from coming into contact with corrosive substances, thereby enhancing its resistance to corrosion. Melt extract stainless steel fibers are made using a process called melt extraction, which ensures the fibers retain the desirable properties of stainless steel, including its corrosion resistance. Therefore, melt extract stainless steel fibers are highly resistant to corrosion, making them suitable for applications in harsh environments, such as marine, chemical, and industrial settings.

- Q: Can melt extract stainless steel fiber be used in shotcrete tunnel boring machine applications?

- Yes, melt extract stainless steel fiber can be used in shotcrete tunnel boring machine applications. Shotcrete is a method of applying concrete or mortar using a high-pressure hose, and the addition of stainless steel fiber can enhance the mechanical properties and durability of the shotcrete. The melt extract stainless steel fiber is made from stainless steel through a melting and extraction process, resulting in a high-strength fiber with excellent corrosion resistance. These properties make it suitable for use in tunnel boring machine applications where the shotcrete needs to withstand high pressures, vibrations, and potential exposure to moisture or chemicals. Additionally, the stainless steel fiber can improve the flexural and tensile strength of the shotcrete, reducing the risk of cracking and enhancing the overall stability and performance of the tunnel structure.

- Q: Can melt extract stainless steel fiber be used in decorative precast concrete applications?

- Yes, melt extract stainless steel fiber can be used in decorative precast concrete applications. These fibers are commonly used in concrete to enhance its strength, durability, and resistance to cracking. In decorative precast concrete, the fibers can be added to the mix to provide additional reinforcement and prevent shrinkage cracks, which can affect the appearance and longevity of the finished product. The use of melt extract stainless steel fibers can also improve the overall aesthetic appeal of decorative precast concrete. These fibers come in various sizes and shapes, allowing for creative and intricate designs to be achieved. They can be used to create unique textures, patterns, and finishes on the surface of the concrete, enhancing its visual appeal and making it suitable for a wide range of decorative applications. Additionally, melt extract stainless steel fibers are highly corrosion-resistant, which is crucial for decorative precast concrete applications that are exposed to harsh environmental conditions or in areas with high moisture content. This ensures that the concrete remains intact and maintains its appearance over time. In summary, melt extract stainless steel fiber is a suitable choice for decorative precast concrete applications. It provides added strength, durability, and resistance to cracking, while also allowing for creative designs and maintaining the desired aesthetic appeal.

- Q: What is the recommended curing regime when using melt extract stainless steel fiber in concrete?

- The recommended curing regime when using melt extract stainless steel fiber in concrete is typically similar to the conventional curing methods for regular concrete. This includes moist curing for a minimum of seven days, ensuring that the concrete remains adequately hydrated during this period. This allows the stainless steel fibers to properly bond with the concrete matrix, enhancing its overall strength and durability.

- Q: Can melt extract stainless steel fiber be used in the construction of dams?

- Yes, melt extract stainless steel fiber can be used in the construction of dams. It is commonly used as a reinforcing material in concrete to enhance its strength, durability, and resistance to cracking. This makes it suitable for constructing dams, which require high strength and structural integrity to withstand water pressure and other environmental factors.

- Q: Can melt extract stainless steel fiber be used in tunnel lining applications?

- Melt extract stainless steel fiber is suitable for tunnel lining applications. It possesses high tensile strength, corrosion resistance, and durability, making it an ideal material for reinforcing tunnel linings. By enhancing the structural integrity and stability of the tunnel, it effectively prevents cracking, spalling, and other types of damage. Moreover, stainless steel fibers offer excellent fire resistance properties, which are crucial in tunnel environments. In summary, melt extract stainless steel fiber is a robust and resilient option for tunnel lining applications, capable of withstanding the challenging conditions commonly encountered in tunnels.

- Q: How does melt extract stainless steel fiber improve the resistance to corrosion in concrete?

- Melt extract stainless steel fiber improves the resistance to corrosion in concrete through several mechanisms. Firstly, the stainless steel fibers act as a physical barrier, preventing harmful substances such as chlorides and sulfates from penetrating the concrete and reaching the reinforcing steel. This barrier effect reduces the exposure of the steel to corrosive agents, thus minimizing the risk of corrosion. Secondly, stainless steel is inherently corrosion-resistant due to its high chromium content. This alloying element forms a passive oxide layer on the surface of the steel, which acts as a protective barrier against corrosion. When stainless steel fibers are incorporated into concrete, this passive oxide layer helps to shield the embedded steel from corrosive attacks, enhancing the overall durability and lifespan of the concrete structure. Furthermore, the addition of melt extract stainless steel fibers improves the mechanical properties of concrete, making it more resistant to cracking and shrinkage. By reducing the occurrence of cracks and minimizing the permeability of the concrete, the ingress of corrosive agents is significantly reduced, thereby enhancing the corrosion resistance of the concrete. Additionally, the high tensile strength and ductility of stainless steel fibers provide an additional layer of reinforcement within the concrete matrix. This reinforcement helps to distribute stress more evenly throughout the structure, preventing localized areas of weakness that could lead to corrosion initiation. In summary, melt extract stainless steel fiber improves the resistance to corrosion in concrete by acting as a physical barrier, providing inherent corrosion resistance, enhancing the mechanical properties of concrete, and providing additional reinforcement. These combined effects contribute to the long-term durability and corrosion resistance of concrete structures in various environments.

- Q: Can melt extract stainless steel fiber replace traditional reinforcement in concrete structures?

- Stainless steel fibers extracted through the melt process can serve as an alternative to conventional reinforcement in concrete structures. These fibers possess various advantages compared to traditional reinforcement, including enhanced strength and durability. During the concrete mixing process, these fibers are evenly dispersed throughout the entire structure. Employing stainless steel fibers can effectively reduce or even eliminate the necessity for customary reinforcement methods like steel bars or mesh. This can result in significant cost savings, as the installation of steel bars or mesh can be both time-consuming and expensive. Moreover, stainless steel fibers exhibit superior crack control capabilities, as they proficiently distribute and confine cracks that may occur in the concrete. Consequently, this can improve the overall performance and lifespan of the structure. Furthermore, stainless steel fibers are resistant to corrosion, which represents a noteworthy advantage over traditional reinforcement. Over time, steel bars or mesh can corrode, leading to structural deterioration. By utilizing stainless steel fibers, the risk of damage caused by corrosion is greatly diminished. Nevertheless, it is crucial to consider that the use of stainless steel fibers as a substitute for traditional reinforcement should be evaluated on a case-by-case basis. Factors such as the structure's type, size, loading conditions, and desired design life must be taken into account. Consulting structural engineers and adhering to proper design guidelines and codes is imperative to ensure the successful utilization of stainless steel fibers as reinforcement in concrete structures.

- Q: What is the effect of melt extract stainless steel fiber on the workability of concrete?

- The addition of melt extract stainless steel fiber to concrete can have a significant effect on its workability. Stainless steel fibers are typically added to concrete to enhance its mechanical properties and improve its resistance to cracking, impact, and abrasion. One of the main benefits of using stainless steel fiber in concrete is that it increases its tensile strength and flexural strength. This means that the concrete becomes more resistant to bending or cracking under pressure, which is particularly important in structural applications. The incorporation of stainless steel fibers also enhances the overall durability and long-term performance of the concrete. However, the addition of stainless steel fibers can also have some drawbacks in terms of workability. The fibers can cause an increase in the viscosity of the concrete mix, making it more difficult to handle and place. This can result in a decrease in the fluidity and cohesiveness of the mix, making it harder to achieve the desired finish and surface texture. To overcome these challenges, it is important to carefully control the dosage and length of the stainless steel fibers used in the concrete mix. By optimizing the fiber content and distribution, it is possible to maintain a good balance between workability and the desired mechanical properties. In summary, the effect of melt extract stainless steel fiber on the workability of concrete is a trade-off between improved mechanical properties and potential challenges in handling and placing the mix. With careful consideration of the fiber dosage and mix design, it is possible to achieve a concrete mix that provides both enhanced performance and satisfactory workability.

- Q: Can melt extract stainless steel fiber be used in underground construction applications?

- Yes, melt extract stainless steel fiber can be used in underground construction applications. The unique properties of stainless steel make it highly suitable for such applications. Stainless steel fibers are known for their high tensile strength, corrosion resistance, and durability, which are important factors in underground construction where structures are exposed to harsh environmental conditions and potential corrosion. The melt extract stainless steel fibers can be used in a variety of underground construction applications. For example, they can be added to concrete mixes to enhance its strength, crack resistance, and overall performance. The fibers distribute uniformly throughout the concrete, providing reinforcement and preventing the propagation of cracks. This is particularly beneficial in underground structures where the concrete may be subjected to high pressures or frequent ground movements. Moreover, the corrosion resistance of stainless steel fibers ensures that they can withstand exposure to moisture and chemicals commonly found in the underground environment. This helps to maintain the structural integrity of the construction and prolong its service life. In addition to concrete reinforcement, melt extract stainless steel fibers can also be used in shotcrete applications. Shotcrete is commonly used in underground construction for lining tunnels, shafts, and other structures. The addition of stainless steel fibers enhances the toughness and ductility of the shotcrete, making it more resistant to cracking and spalling. Furthermore, the use of stainless steel fibers in underground construction can contribute to increased safety. The fibers help to control the propagation of cracks, thereby reducing the risk of sudden structural failures. This is especially important in underground structures where the consequences of a collapse could be catastrophic. Overall, the use of melt extract stainless steel fibers in underground construction applications offers numerous benefits. Their high tensile strength, corrosion resistance, and durability make them an ideal choice for reinforcing concrete and shotcrete in underground structures. By enhancing the performance and longevity of the construction, these fibers contribute to the overall safety and reliability of underground projects.

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type Steel Fiber by CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords