Melt Extract Stainless Steel Fiber - Straight Type Steel Fiber from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Shandong, China (Mainland)

Brand Name: CNBM

Model Number: LONGSTONE

Material: Stainless Steel

Specifications

Specifications

Produces shear type, steel wire type, cut type, stainless type, and micro wire type steel fiber. It is used for concret.

SPECIFICATION

TYPE | SIZE | tensile strength |

ENDHOOKED STEEL FIBER | 0.5×0.5×30 mm | 850Mpa min |

0.6×0.7×35 mm | 850Mpa min | |

0.5×0.5×30 mm | 1000MPA min | |

0.6×35 mm | 1000MPA min | |

0.9×60 mm | 1000MPA min | |

CORRUGATED STEEL FIBER | 0.25×0.25×10 mm | 380Mpa min |

0.25×0.25×14 mm | 380Mpa min | |

0.5×0.7×32 mm | 380MPA min |

OTHER SPECIFICATIONS CAN BE DISCUSSED AS PER BUYER’S OPTION

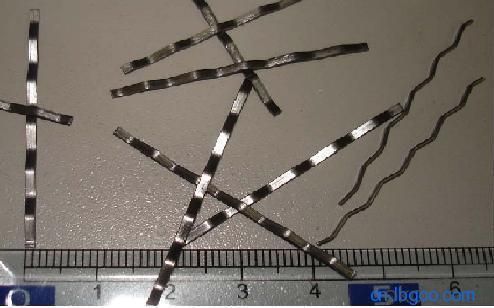

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: Can melt extract stainless steel fiber be used in ultra-high-performance concrete (UHPC)?

- Indeed, melt extract stainless steel fiber is a viable option for utilization in ultra-high-performance concrete (UHPC). UHPC is renowned for its outstanding robustness, endurance, and augmented performance attributes, and the inclusion of stainless steel fibers can further heighten these qualities. Melt extract stainless steel fibers are specifically engineered to enhance the tensile strength, malleability, and resistance to fissuring of concrete. Furthermore, they offer exceptional resistance to corrosion, which is pivotal for long-lasting sustainability in aggressive surroundings. Moreover, the diminutive diameter and elevated aspect ratio of these fibers facilitate enhanced dispersion and adhesion within the concrete structure, resulting in improved crack resistance and overall performance. Consequently, integrating melt extract stainless steel fibers in UHPC can significantly enhance its mechanical properties and lifespan, rendering it a suitable option for demanding applications such as skyscrapers, infrastructure undertakings, and precast elements.

- Q: Can melt extract stainless steel fiber be used in marine or coastal structures?

- Indeed, melt extract stainless steel fiber is applicable in marine or coastal structures. Stainless steel is renowned for its exceptional resistance to corrosion, rendering it a prime selection for structures continuously subjected to moisture and saltwater. The melt extract procedure additionally augments the fiber's ability to resist corrosion, thereby guaranteeing its longevity in marine or coastal settings. Moreover, stainless steel fibers possess substantial tensile strength and can bolster the concrete's structural integrity, rendering them appropriate for employment in diverse marine or coastal structures such as seawalls, piers, and offshore platforms.

- Q: Does melt extract stainless steel fiber enhance the crack resistance of concrete?

- Concrete's crack resistance is enhanced by melt extract stainless steel fiber. To improve the tensile strength and prevent crack formation and propagation, stainless steel fibers are added to concrete mixes. Acting as reinforcement within the concrete matrix, these fibers provide additional strength and durability. When evenly dispersed throughout the concrete, these fibers form a three-dimensional network that helps distribute stress and load more uniformly. This reduces the likelihood of cracks forming and spreading, ultimately enhancing the concrete's overall crack resistance. Melt extract stainless steel fibers possess a high melting point and excellent corrosion resistance, making them highly effective in harsh environments or when exposed to chemicals. These fibers can endure high temperatures and prevent spalling or cracking of the concrete under extreme conditions. Moreover, the inclusion of stainless steel fibers improves the impact resistance and flexural strength of the concrete, rendering it more resilient to cracking caused by external forces or dynamic loads. In summary, melt extract stainless steel fiber positively contributes to the crack resistance of concrete by reinforcing the material and enhancing its tensile strength. Consequently, this leads to a more enduring and long-lasting concrete structure.

- Q: Is melt extract stainless steel fiber suitable for use in marine environments?

- Melt extract stainless steel fiber is indeed suitable for marine environments due to its corrosion resistance properties. This type of stainless steel is well-known for its ability to withstand the harmful effects of saltwater and other corrosive elements commonly found in marine settings. Specifically engineered to possess enhanced strength and durability, melt extract stainless steel fiber is an excellent option for applications that will be subjected to the challenging conditions of the marine environment. Moreover, the fiber's high melting point and capacity to endure extreme temperatures make it highly suitable for marine applications involving exposure to intense heat. In conclusion, melt extract stainless steel fiber is a dependable and efficient choice for marine environments.

- Q: How does melt extract stainless steel fiber enhance the toughness of concrete?

- Melt extract stainless steel fiber, a reinforcement material used in concrete, greatly enhances its toughness. The process involves melting stainless steel and rapidly cooling it to form thin, elongated fibers. When these stainless steel fibers are added to concrete, they provide multiple mechanisms to improve its toughness. Firstly, they act as micro-reinforcements, dispersing throughout the concrete matrix and creating a three-dimensional network. This network evenly distributes loads, preventing crack propagation and enhancing the overall strength and durability of the concrete. Moreover, the high tensile strength of stainless steel fibers allows them to bridge cracks that may form in the concrete. This bridging effect maintains the structure's integrity by preventing cracks from widening or spreading. Consequently, the concrete becomes more resistant to impact, cyclic loading, and other types of mechanical stress. Additionally, the presence of stainless steel fibers in concrete enhances its resistance to shrinkage and cracking during the curing process. The fibers reinforce against the tensile forces that arise as the concrete dries and shrinks. This reduces the likelihood of cracks forming, further improving the toughness and durability of the concrete. In conclusion, melt extract stainless steel fiber improves the toughness of concrete by creating a three-dimensional network, bridging cracks, and enhancing resistance to shrinkage and cracking. Incorporating stainless steel fibers into concrete significantly enhances its strength, durability, and structural integrity, making it the preferred choice for high-performance concrete applications.

- Q: Can melt extract stainless steel fiber be used in pre-stressed concrete applications?

- Yes, melt extract stainless steel fiber can be used in pre-stressed concrete applications. The high tensile strength and corrosion resistance of stainless steel fibers make them suitable for reinforcing concrete structures that are subjected to pre-stressing forces. These fibers can enhance the durability and structural integrity of pre-stressed concrete elements, providing additional strength and preventing cracking or failure under tension.

- Q: How does the presence of melt extract stainless steel fiber affect the creep behavior of concrete?

- Concrete's creep behavior is significantly affected by the presence of melt extract stainless steel fiber. Creep refers to the gradual deformation of concrete over time when subjected to a sustained load. As a reinforcement material, melt extract stainless steel fibers enhance the tensile strength and overall performance of concrete. These fibers are typically added to the concrete mixture during the mixing process. Their addition creates a three-dimensional network within the concrete matrix, promoting a more even distribution of the applied load. One of the main benefits of melt extract stainless steel fibers is the reduction of creep in concrete. Acting as internal reinforcements, these fibers effectively restrict the movement and deformation of the concrete under load over time. Consequently, the presence of these fibers improves the long-term stability and durability of concrete structures by minimizing creep-induced deformations. Furthermore, melt extract stainless steel fibers also improve the cracking resistance of concrete. By reinforcing the concrete matrix, these fibers help control the propagation of cracks, preventing their enlargement and reducing the potential for further damage. This is particularly crucial in structures exposed to high loads or thermal variations, as it maintains the integrity of the concrete over time. In addition to reducing creep and enhancing cracking resistance, melt extract stainless steel fibers also enhance the overall mechanical properties of concrete. They increase its flexural strength, impact resistance, and fatigue resistance, making it more resilient to various types of loads and stresses. To summarize, the presence of melt extract stainless steel fibers in concrete positively impacts its creep behavior. It reduces deformation under sustained load, improves cracking resistance, and enhances the overall mechanical properties of concrete. Consequently, this leads to a more durable and long-lasting construction material.

- Q: How does melt extract stainless steel fiber enhance the resistance of concrete to corrosion?

- Melt extract stainless steel fiber enhances the resistance of concrete to corrosion through its unique properties and characteristics. When added to concrete as a reinforcement material, stainless steel fiber acts as a barrier against corrosive agents and prevents their penetration into the concrete matrix. One of the main reasons why stainless steel fiber is effective in enhancing corrosion resistance is its high corrosion resistance itself. Stainless steel is composed of iron, chromium, and other alloying elements that create a protective oxide layer on its surface. This oxide layer acts as a shield against corrosive elements such as chloride ions, which are one of the main causes of corrosion in concrete structures. As a result, the stainless steel fiber prevents the penetration of chloride ions into the concrete, reducing the risk of corrosion. Furthermore, the presence of stainless steel fiber in concrete also improves the overall durability and lifespan of the structure. Stainless steel fibers help to increase the tensile strength and flexural strength of concrete, making it less prone to cracking or spalling. By reinforcing the concrete matrix, stainless steel fiber enhances its ability to withstand external loads and environmental factors, including corrosive agents. Additionally, stainless steel fiber has a high aspect ratio, meaning it is relatively long and thin. This characteristic allows the fibers to create a three-dimensional reinforcement network within the concrete, improving its resistance to cracking and reinforcing its overall structure. This network of fibers also acts as a physical barrier that prevents the movement of corrosive elements, such as water and oxygen, within the concrete, further reducing the risk of corrosion. In conclusion, melt extract stainless steel fiber enhances the resistance of concrete to corrosion by providing a high level of corrosion resistance, improving the overall durability and lifespan of the structure, and creating a three-dimensional reinforcement network within the concrete. These properties make stainless steel fiber an effective solution for enhancing the corrosion resistance of concrete structures, ultimately increasing their longevity and reducing maintenance and repair costs.

- Q: Can melt extract stainless steel fiber improve the resistance of concrete to fire?

- Yes, melt extract stainless steel fiber can improve the resistance of concrete to fire. Stainless steel fibers are known for their high melting point, corrosion resistance, and excellent heat conductivity, making them an ideal choice for enhancing the fire resistance of concrete. When added to concrete, these fibers create a three-dimensional reinforcement network that helps to prevent cracks and spalling during fire exposure. The stainless steel fibers also act as a heat sink, absorbing and dissipating heat more efficiently, which can significantly delay the temperature rise in the concrete, thus increasing its fire resistance. Additionally, the fibers enhance the overall strength and durability of the concrete, making it more resilient to fire and prolonging its structural integrity under high temperatures. Therefore, incorporating melt extract stainless steel fiber into concrete can indeed improve its resistance to fire.

- Q: What is the effect of melt extract stainless steel fiber on the creep behavior of concrete?

- The addition of melt extract stainless steel fiber to concrete can have a significant effect on its creep behavior. Creep is the time-dependent deformation of concrete under sustained loading, and it is a critical property to consider in many construction applications. When stainless steel fibers are incorporated into concrete, they act as reinforcement and help to enhance its mechanical properties, including its resistance to creep. The high tensile strength and ductility of stainless steel fibers provide additional support to the concrete matrix, reducing the potential for creep deformation. The presence of stainless steel fibers in concrete also helps to distribute the load more evenly throughout the structure, preventing localized stress concentrations that can lead to creep. This improved load distribution enhances the overall durability and long-term performance of the concrete. Furthermore, melt extract stainless steel fibers have excellent corrosion resistance, which is crucial in concrete applications exposed to harsh environments or aggressive chemical substances. By preventing corrosion and degradation of the fibers, the creep behavior of the concrete remains stable over time. In summary, the addition of melt extract stainless steel fiber to concrete can significantly improve its resistance to creep deformation. The fibers reinforce the concrete matrix, enhance load distribution, and provide corrosion resistance, resulting in a more durable and long-lasting concrete structure.

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type Steel Fiber from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords