Melt Extract Stainless Steel Fiber Slit Sheet 330

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

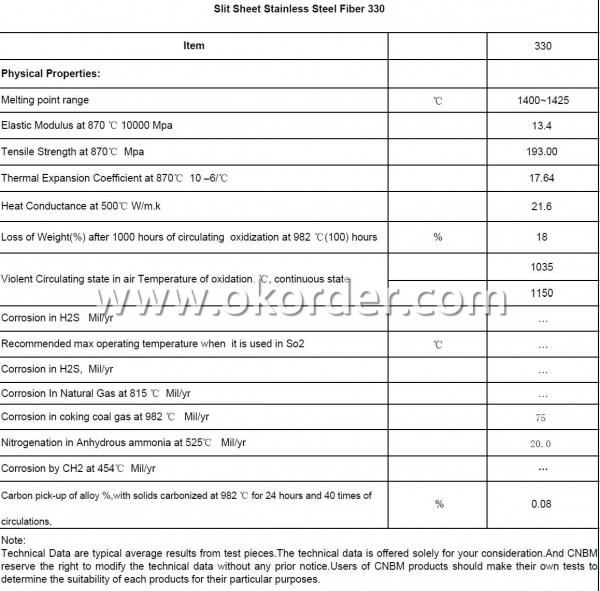

General Information of Slit Sheet Stainless Steel Fiber 330

CMAX cold drawn stainless steel fiber is manufactured by high quality stainless steel wire, mainly used for castable requirements in refractory field, with high tensile strength and low ductility. It can improve refractory performance. Our products can save labor costs.

CMAXmelt extract stainless steel fibercan improve refractories performance and durability, decreasing cost.

CMAX Slit Sheet Stainless Steel Fiber 330 has good performance with the following characteristics:

Light weight

Improve refractories’ performance

Improve refractories’ longevity

Improve refractories’ durability

Significantly reducing downtime and maintance cost

CMAX Slit Sheet Stainless Steel Fiber 330 is available in a wide variety of application:

Refractory products

Precast

Castable project

Industrial furnaces

Other refractories project

Our steel fiber is widely used in the world.Our company has success in its melt extract stainless steel fiberproducts due to their cost-effectiveness and excellent insulating properties. We also have experience in melt extract stainless steel fiberapplication and would like to assist you in product selection, system design, and installation techniques. We can serve the good quality of melt extract stainless steel fiber, We look forward to your cooperation .

- Q: Can melt extract stainless steel fiber be used in retaining wall construction?

- Yes, melt extract stainless steel fiber can be used in retaining wall construction. It provides added strength, durability, and resistance to cracking, making it a suitable material for reinforcing concrete in retaining walls.

- Q: About how much is the steel fiber?

- According to the raw materials and production process to distinguish: the use of ordinary strip steel and genuine stainless steel band produced products, prices vary greatly

- Q: How does melt extract stainless steel fiber enhance the durability of concrete structures?

- The durability of concrete structures is greatly improved by the addition of melt extract stainless steel fiber. These fibers provide various advantages that contribute to the overall strength and longevity of the structure. To begin with, melt extract stainless steel fibers play a crucial role in enhancing the resistance to cracking in concrete. Acting as reinforcement, these fibers distribute stress and minimize the formation of shrinkage cracks. This is especially important in environments with extreme temperature variations or heavy loads, as it prevents the development of cracks that could compromise the structure's integrity. Furthermore, stainless steel fibers enhance the toughness and impact resistance of concrete. By dispersing throughout the concrete matrix, they create a three-dimensional network of reinforcement that improves the material's ability to absorb and distribute energy upon impact. This increased toughness prevents cracks from spreading, making the structure more durable and resistant to damage from external forces. Another significant advantage of melt extract stainless steel fibers is their ability to enhance the resistance to corrosion in concrete structures. Stainless steel is naturally resistant to rust and oxidation, even in harsh environments. By incorporating these fibers into the concrete mix, an additional layer of protection against corrosion is provided, thereby increasing the lifespan of the structure and reducing the need for maintenance and repair. Additionally, the use of melt extract stainless steel fibers can improve the fire resistance of concrete structures. Due to its high melting point, stainless steel helps delay structural failure under high temperatures when added to concrete. This is particularly important in buildings and structures where fire safety is a critical concern. In conclusion, the incorporation of melt extract stainless steel fibers significantly enhances the durability of concrete structures. By improving resistance to cracking, increasing toughness and impact resistance, enhancing corrosion resistance, and improving fire resistance, these fibers ensure that the concrete structure remains strong and intact for a longer period, reducing the need for repairs and replacements and ultimately saving costs.

- Q: Does melt extract stainless steel fiber improve the durability of concrete in marine environments?

- Yes, melt extract stainless steel fiber can improve the durability of concrete in marine environments. Stainless steel fibers are resistant to corrosion, making them ideal for use in marine environments where concrete is constantly exposed to saltwater and other corrosive elements. These fibers provide reinforcement to the concrete, increasing its tensile strength and reducing cracking, which can further protect the concrete from the damaging effects of water and salt. Additionally, stainless steel fibers can enhance the overall durability and longevity of concrete structures in marine environments by improving their resistance to abrasion and impact. Therefore, the use of melt extract stainless steel fibers in concrete can significantly enhance its durability in marine environments.

- Q: Can melt extract stainless steel fiber be used in industrial chimney construction?

- Yes, melt extract stainless steel fiber can be used in industrial chimney construction. This type of fiber is known for its high temperature resistance, making it suitable for applications in high-temperature environments such as chimneys. It can provide reinforcement and enhance the strength and durability of the chimney structure. Additionally, melt extract stainless steel fiber is also resistant to corrosion, which is important for chimneys that are exposed to various chemicals and pollutants. Overall, using melt extract stainless steel fiber in industrial chimney construction can improve the chimney's performance, longevity, and safety.

- Q: How does melt extract stainless steel fiber affect the carbonation resistance of concrete?

- The addition of melt extract stainless steel fiber can greatly improve the resistance of concrete to carbonation. Carbonation is a chemical process in which carbon dioxide from the atmosphere reacts with the calcium hydroxide in concrete, forming calcium carbonate. This process can decrease the alkalinity of the concrete, leading to corrosion of embedded reinforcement and a decrease in the overall durability of the structure. When melt extract stainless steel fiber is incorporated into concrete, it forms a three-dimensional reinforcement network, which enhances both the mechanical properties and durability of the concrete. These stainless steel fibers act as a physical barrier, reducing the entry of carbon dioxide into the concrete matrix. This barrier effect slows down the carbonation process, effectively increasing the concrete's resistance to carbonation. Moreover, the stainless steel fibers also improve the mechanical properties of the concrete, making it more resistant to cracking and spalling. This increased resistance to cracking further reduces the potential for carbon dioxide to penetrate the concrete, as cracks serve as pathways for gas diffusion. Additionally, the stainless steel fibers provide an extra layer of corrosion protection to the embedded reinforcement, helping to mitigate the effects of carbonation. The fibers function as sacrificial anodes, redirecting any potential corrosion initiation sites away from the reinforcement and onto themselves. This sacrificial anode effect prolongs the service life of the concrete structure by reducing the risk of reinforcement corrosion caused by carbonation. In conclusion, the melt extract stainless steel fiber has a positive impact on the carbonation resistance of concrete by acting as a physical barrier, enhancing mechanical properties, and providing additional corrosion protection to the embedded reinforcement. These advantages contribute to increased durability and extended service life of concrete structures in environments prone to carbonation.

- Q: What is the recommended fiber dosage when using melt extract stainless steel fiber in shotcrete?

- The recommended fiber dosage when using melt extract stainless steel fiber in shotcrete typically ranges from 25 to 40 kg/m3, depending on the specific requirements of the project and the desired performance characteristics.

- Q: Is melt extract stainless steel fiber compatible with all types of concrete additives?

- No, melt extract stainless steel fiber may not be compatible with all types of concrete additives. Compatibility depends on the specific type and properties of the additives used. It is important to consult with manufacturers and conduct compatibility tests to ensure proper performance and compatibility when using melt extract stainless steel fiber with concrete additives.

- Q: What is the diameter range of melt extract stainless steel fiber?

- The diameter range of melt extract stainless steel fibers typically falls between 5 to 50 micrometers.

- Q: Can melt extract stainless steel fiber be used in fiber-reinforced polymers (FRP)?

- Yes, melt extract stainless steel fiber can be used in fiber-reinforced polymers (FRP). Stainless steel fibers are commonly used in FRP composites to enhance their mechanical properties such as strength, stiffness, and toughness. These fibers are typically added to the polymer matrix during the manufacturing process to improve the overall performance of the composite material. The melt extract stainless steel fibers have excellent corrosion resistance, high tensile strength, and good thermal stability, making them suitable for use in FRP applications where durability and reliability are important. Additionally, the presence of stainless steel fibers can also provide electromagnetic shielding properties to the FRP composites, making them suitable for certain applications such as in the aerospace or automotive industries. Overall, melt extract stainless steel fibers can be effectively used in fiber-reinforced polymers to enhance their mechanical and functional properties.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Melt Extract Stainless Steel Fiber Slit Sheet 330

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords