Melt Extract Stainless Steel Fiber 310 - High Quality Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

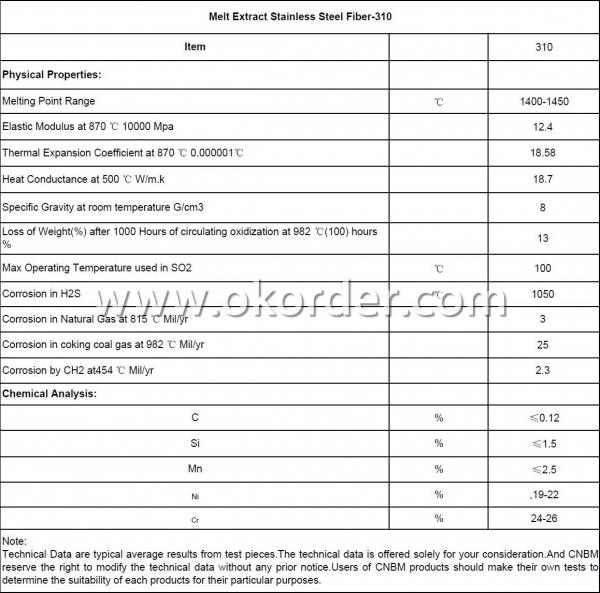

General Information of Melt Extract Stainless Steel Fiber 310

CMAX melt extract stainless steel fiber 310 is produced by melting elements in a crucible packing by paper boxes. A flywheel is then introduced to the crucible and droplets of molten metal are spun into the open air and hardened. CMAX melt extract stainless steel fibers are spun directly from the melt using the company's advanced Melt Extraction (ME) and Melt Overflow (MO) processes. CMAX melt extract stainless steel fiber can increase the lifetime of refractory materials and industrial furnaces by several times, decreasing cost and saving labor costs.

CMAX Melt Extract Stainless Steel Fiber 310 exhibits the following characteristics:

Improve refractories’ performance

Improve refractories’ longevity

Improve refractories’ durability

Significantly reducing downtime and maintance cost

CMAX Melt Extract Stainless Steel Fiberis 310 available in a wide variety of application:

CMAX Melt Extract Stainless Steel Fiberis 310 available in a wide variety of application:

Refractory products

Precast

Castable project

Industrial furnaces

Other refractories project

Our company has success in its melt extract stainless steel fiberproducts due to their cost-effectiveness and excellent insulating properties. We also have experience in melt extract stainless steel fiberapplication and would like to assist you in product selection, system design, and installation techniques. Our products of melt extract stainless steel fiber are in good quality and in best price and we are looking forward for your enquiry.

- Q: Can melt extract stainless steel fiber be used in pre-stressed concrete elements?

- Melt extract stainless steel fibers, known for their durability and excellent reinforcement properties, are suitable for pre-stressed concrete elements. By utilizing these fibers, the load-bearing capacity, crack resistance, and structural integrity of the concrete structures can be greatly improved. Moreover, the high tensile strength and corrosion resistance of stainless steel fibers make them perfect for environments with moisture or chemical exposure. Overall, incorporating melt extract stainless steel fibers in pre-stressed concrete elements can substantially enhance the structure's performance and lifespan.

- Q: Can melt extract stainless steel fiber be used in thin concrete sections?

- Yes, melt extract stainless steel fiber can be used in thin concrete sections. The addition of stainless steel fibers to thin concrete sections helps to enhance the mechanical properties and overall performance of the concrete. These fibers provide reinforcement and improve the resistance to cracking and shrinkage, which is particularly important in thin sections where the concrete is more vulnerable to these issues. The stainless steel fibers also increase the durability and longevity of the concrete, making it suitable for various applications, including thin sections.

- Q: Can melt extract stainless steel fiber be used in shotcrete tunnel boring machine applications?

- Melt extract stainless steel fiber is indeed applicable in shotcrete tunnel boring machine applications. Shotcrete, which involves the application of concrete or mortar through a high-pressure hose, can benefit from the addition of stainless steel fiber. This addition enhances the shotcrete's mechanical properties and durability. The stainless steel fiber is produced through a melting and extraction process, resulting in a high-strength fiber that exhibits excellent corrosion resistance. These desirable qualities make it well-suited for tunnel boring machine applications where the shotcrete must withstand high pressures, vibrations, and potential exposure to moisture or chemicals. Moreover, the stainless steel fiber contributes to improved flexural and tensile strength of the shotcrete, thereby minimizing the risk of cracking and bolstering the overall stability and performance of the tunnel structure.

- Q: Can melt extract stainless steel fiber be used in marine structures?

- Yes, melt extract stainless steel fiber can be used in marine structures. Stainless steel is known for its corrosion resistance, making it suitable for use in marine environments where exposure to saltwater and high humidity is common. The melt extract stainless steel fibers can reinforce concrete or other construction materials used in marine structures, providing added strength and durability. These fibers are resistant to rust and can withstand the harsh conditions found in marine environments, making them an excellent choice for marine structures such as piers, docks, and offshore platforms. Additionally, the use of stainless steel fibers can help improve the overall performance and lifespan of these structures, reducing maintenance and repair costs in the long run.

- Q: Can melt extract stainless steel fiber be used in railway sleepers?

- Certainly, melt extract stainless steel fiber is applicable for utilization in railway sleepers. Known for its exceptional resistance to corrosion and fatigue, stainless steel fiber serves as a robust material. By incorporating it into railway sleepers, the overall strength and longevity of the sleepers are significantly enhanced, rendering them suitable for heavy train loads and extended service life. The melt extract process guarantees the uniform and consistent shape of the stainless steel fibers, thereby further augmenting their performance and dependability. Moreover, the utilization of stainless steel fiber aids in the prevention of crack formation and improves resistance to thermal expansion and contraction, making it an ideal selection for railway sleepers.

- Q: Can melt extract stainless steel fiber be used in high-temperature environments?

- Yes, melt extract stainless steel fiber can be used in high-temperature environments. This type of fiber is specifically designed to withstand extreme heat and maintain its structural integrity, making it suitable for applications where temperatures are elevated.

- Q: What is the effect of melt extract stainless steel fiber on the thermal conductivity of concrete?

- The inclusion of melt extract stainless steel fiber in concrete tends to enhance its thermal conductivity. The fibers act as heat conductors within the concrete matrix, facilitating the transfer of heat throughout the material. This results in improved thermal conductivity and better heat distribution within the concrete structure.

- Q: Can melt extract stainless steel fiber be used in fiber-reinforced shotcrete applications?

- Indeed, melt extract stainless steel fiber is a viable option for incorporating into fiber-reinforced shotcrete applications. Shotcrete, a method involving the pneumatic projection of concrete onto a surface, can greatly benefit from the addition of this type of reinforcement material. By introducing stainless steel fibers into the shotcrete mixture, the resulting composite becomes more resilient and less prone to cracking. These stainless steel fibers have the ability to improve the ductility, toughness, and overall efficacy of the shotcrete, rendering it suitable for a wide range of applications, such as tunnels, bridges, and retaining walls. The melt extract process employed to fabricate the stainless steel fibers ensures the production of a high-quality product with consistent properties. These fibers are specifically engineered to withstand the forces and stresses encountered during the shotcrete application, thereby providing supplementary reinforcement to the concrete matrix. Within fiber-reinforced shotcrete applications, the stainless steel fibers are evenly dispersed throughout the mixture, effectively bolstering its tensile and flexural strength. This reinforcement aids in controlling cracking, enhancing impact resistance, and augmenting the overall longevity of the shotcrete structure. Furthermore, melt extract stainless steel fibers boast exceptional resistance to corrosion, rendering them well-suited for shotcrete applications in aggressive environments, such as those characterized by marine or chemical exposure conditions. In conclusion, melt extract stainless steel fiber serves as a valuable asset in fiber-reinforced shotcrete applications, elevating the strength, durability, and performance of the shotcrete material.

- Q: Can melt extract stainless steel fiber be used in the construction of water storage tanks?

- Yes, melt extract stainless steel fiber can be used in the construction of water storage tanks. Stainless steel fibers are known for their high corrosion resistance and durability, making them suitable for use in water storage tanks where they can withstand the corrosive nature of water and provide structural reinforcement.

- Q: What is the effect of melt extract stainless steel fiber on the curing time of concrete?

- Concrete's curing time can be significantly influenced by the addition of melt extract stainless steel fiber. Typically, stainless steel fibers are incorporated into concrete mixtures to enhance its mechanical properties, including strength, durability, and resistance to cracks. The presence of stainless steel fibers in concrete primarily impacts the curing time by improving the bond between the cement matrix and the aggregate. This improved bond leads to a faster rate of hydration, which is the chemical reaction between the cement and water that results in concrete hardening. As a result of this enhanced hydration process, concrete containing melt extract stainless steel fibers generally experiences quicker initial setting and strength development. Consequently, the concrete can achieve a sufficient level of hardness and strength more rapidly compared to plain concrete without fibers, ultimately reducing the overall curing time. Moreover, the use of stainless steel fibers also helps minimize plastic shrinkage cracking, which commonly occurs during the early stages of concrete curing when water content evaporates faster than the hydration reaction takes place. By reducing these cracks, the curing time can be further expedited as there is less need for repair or remediation. However, it is important to acknowledge that the specific impact of melt extract stainless steel fiber on curing time can vary based on factors such as fiber dosage, aggregate type, environmental conditions, and overall concrete mixture design. Therefore, it is crucial to conduct thorough testing and analysis to determine the precise influence of stainless steel fibers on the curing time of concrete in a specific application.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Melt Extract Stainless Steel Fiber 310 - High Quality Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords