Melt Extract Stainless Steel Fiber - Straight Type from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

1. Material: low carbon steel wire or stainless steel

2.Diameter: 0.4mm-1.0mm

3.Length: meet your requirements

4.tensile strength >1000Mpa

6.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

7.Uses: highway road surface,tunnel,building,airport road surface and so on .

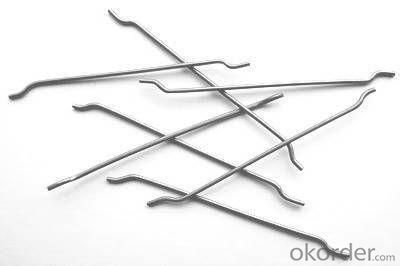

Straight Steel Fiber

1.ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: What is the effect of melt extract stainless steel fiber on the compressive strength of concrete?

- The use of melt extract stainless steel fiber in concrete can have a significant positive effect on its compressive strength. Stainless steel fibers are added to the concrete mixture to enhance its mechanical properties and improve its performance under compressive loading. The inclusion of stainless steel fibers in concrete helps to increase its tensile strength, ductility, and toughness. These fibers act as reinforcement within the concrete matrix, providing additional strength and preventing crack propagation. When subjected to compressive forces, the fibers distribute the stress more evenly throughout the concrete, reducing the concentration of stress points and improving its overall strength. The presence of melt extract stainless steel fibers in concrete can also enhance its resistance to temperature variations, shrinkage, and cracking. This is particularly beneficial in areas where the concrete is exposed to extreme weather conditions or subjected to thermal cycling. Additionally, the use of stainless steel fibers can improve the durability and longevity of concrete structures. The fibers help to inhibit the growth of cracks and prevent their propagation, resulting in a more durable and long-lasting concrete. However, it is important to note that the effect of melt extract stainless steel fibers on the compressive strength of concrete can vary depending on several factors, including the fiber content, aspect ratio, and distribution within the concrete matrix. It is crucial to carefully consider these factors and conduct proper testing to determine the optimal fiber dosage and distribution for achieving the desired compressive strength enhancement. In summary, melt extract stainless steel fibers have a positive effect on the compressive strength of concrete by enhancing its mechanical properties, improving its resistance to cracking, and increasing its durability.

- Q: Can melt extract stainless steel fiber be used in elevated slabs?

- Elevated slabs can utilize melt extract stainless steel fiber. These fibers are renowned for their high tensile strength, exceptional corrosion resistance, and durability. These characteristics make them suitable for various concrete applications, including elevated slabs. When incorporated into elevated slabs, melt extract stainless steel fibers improve the overall strength and performance of the concrete. They reinforce the structure and enhance crack resistance, which is crucial for high load-bearing structures like elevated slabs. Furthermore, melt extract stainless steel fibers aid in controlling shrinkage and minimizing the risk of cracking caused by drying shrinkage in elevated slabs. By reinforcing the entire concrete matrix, they restrict crack propagation and reduce the likelihood of structural damage. Moreover, melt extract stainless steel fibers exhibit excellent resistance against corrosion, ensuring the long-term durability of elevated slabs. This is especially important in environments where the slab is exposed to moisture or chemical substances that could potentially corrode the steel reinforcement. In summary, melt extract stainless steel fibers can significantly enhance the strength, crack resistance, and durability of elevated slabs. However, it is imperative to seek advice from a structural engineer or construction professional to determine the appropriate dosage and installation techniques based on the specific project requirements.

- Q: Can melt extract stainless steel fiber be used in marine structures?

- Yes, melt extract stainless steel fiber can be used in marine structures. Its corrosion resistance properties make it suitable for applications in marine environments where it can withstand exposure to saltwater and moisture without losing its structural integrity.

- Q: Can melt extract stainless steel fiber be used in industrial flooring applications for shotcrete?

- Melt extract stainless steel fiber is a suitable option for shotcrete applications in industrial flooring. Shotcrete is a construction method that involves spraying concrete onto a surface using air pressure, resulting in a fast and efficient way to create a strong and durable floor. By incorporating stainless steel fiber into the shotcrete mix, the overall performance and durability of the flooring system can be enhanced. To produce melt extract stainless steel fiber, stainless steel is melted and then rapidly extracted into fine fibers. These fibers are known for their high tensile strength, resistance to corrosion, and toughness. When added to shotcrete, they contribute to improved crack resistance, impact resistance, and overall durability of the floor. In industrial environments where floors are subjected to heavy loads, impacts, and abrasion, using stainless steel fiber in shotcrete can offer significant advantages. It helps to minimize cracking, enhance resistance to wear and tear, and extend the lifespan of the floor. Moreover, stainless steel fiber can augment the fire resistance of shotcrete flooring, making it appropriate for industrial settings where fire safety is a concern. Overall, melt extract stainless steel fiber is an excellent choice for shotcrete applications in industrial flooring. It provides enhanced performance, durability, and fire resistance, making it a dependable solution for industrial settings that require robust and long-lasting flooring.

- Q: Can melt extract stainless steel fiber be used in high-strength shotcrete applications?

- Yes, melt extract stainless steel fiber can be used in high-strength shotcrete applications. Melt extract stainless steel fibers are known for their excellent mechanical properties, including high tensile strength and superior durability. These fibers are commonly used to enhance the strength and performance of shotcrete, which is a spray-on concrete material. By adding melt extract stainless steel fibers to shotcrete mixtures, the resulting material gains enhanced toughness, crack resistance, and impact resistance. This makes it suitable for high-strength shotcrete applications, where increased structural integrity and durability are required. The stainless steel fibers help to distribute the load and prevent the propagation of cracks, providing an overall stronger and more reliable shotcrete material. Moreover, melt extract stainless steel fibers are resistant to corrosion, which is particularly beneficial in high-strength shotcrete applications that may be exposed to harsh environments or chemicals. The corrosion resistance ensures the long-term durability and performance of the shotcrete, reducing maintenance requirements and increasing its service life. In conclusion, melt extract stainless steel fibers can definitely be used in high-strength shotcrete applications. Their superior mechanical properties and corrosion resistance make them an excellent choice for reinforcing shotcrete, enhancing its strength and durability in demanding construction projects.

- Q: What is the effect of melt extract stainless steel fiber on the permeability of asphalt mixtures?

- Melt extract stainless steel fiber has a positive effect on the permeability of asphalt mixtures. It helps to enhance the compactness and durability of the mixture, reducing the possibility of water infiltration and improving the overall performance of the asphalt pavement. The fiber acts as a reinforcement, reducing cracking and increasing the resistance to rutting and fatigue. Additionally, the stainless steel fiber can help stabilize the asphalt mixture, increasing its resistance to deformation and improving its long-term durability.

- Q: Can melt extract stainless steel fiber be used in concrete repair or rehabilitation?

- Concrete repair or rehabilitation can utilize melt extract stainless steel fiber. To enhance durability, strength, and resistance to cracking, stainless steel fibers are commonly incorporated into concrete mixes. Acting as reinforcement, these fibers reduce shrinkage and prevent crack formation. Furthermore, they bolster impact, abrasion, and corrosion resistance of the concrete. Melt extract stainless steel fibers undergo a specialized melting and extraction process, resulting in high-quality fibers with exceptional mechanical properties. During concrete batching, these fibers are typically added to ensure even distribution throughout the structure. In the context of concrete repair or rehabilitation, melt extract stainless steel fibers can reinforce damaged or deteriorated concrete. They restore structural integrity and prevent further degradation. Additionally, these fibers enhance the bond between repair material and existing concrete, ultimately improving the performance and longevity of the restored structure. It is crucial to adhere to specific guidelines and recommendations provided by manufacturers or industry standards when employing melt extract stainless steel fibers in concrete repair or rehabilitation. Proper dosage, mix design, and application techniques must be followed to achieve optimal performance and durability.

- Q: Can melt extract stainless steel fiber be used in combination with other types of reinforcement?

- Yes, it is possible to use melt extract stainless steel fiber alongside other forms of reinforcement. In concrete, stainless steel fiber is commonly employed as a supplementary reinforcement to enhance its mechanical properties. These properties include ductility, toughness, and resistance to cracking. To optimize the performance of concrete structures, stainless steel fiber can be combined with other forms of reinforcement, such as steel rebars or synthetic fibers. By combining various types of reinforcement, a synergistic effect can be achieved, leading to improved strength and durability. However, it is crucial to carefully consider the compatibility and suitability of different reinforcement materials. Additionally, the design and construction requirements must be taken into account to ensure proper integration and optimal performance.

- Q: Can melt extract stainless steel fiber be used in wastewater treatment plant construction?

- Yes, melt extract stainless steel fiber can be used in wastewater treatment plant construction. Stainless steel fibers are commonly used in construction materials for their high strength, durability, and resistance to corrosion. In wastewater treatment plants, where there is constant exposure to moisture and chemicals, the use of stainless steel fibers can enhance the performance and longevity of the construction materials. These fibers can be incorporated into concrete, cement, or other composite materials to improve their mechanical properties and increase their resistance to cracking, spalling, and deterioration. Additionally, stainless steel fibers can also help to reduce the formation of cracks and enhance the overall structural integrity of the construction elements. Therefore, the use of melt extract stainless steel fibers can be a viable option for wastewater treatment plant construction.

- Q: Can melt extract stainless steel fiber be used in offshore platform construction?

- Melt extract stainless steel fiber is indeed applicable for offshore platform construction. This particular type of stainless steel fiber is renowned for its exceptional tensile strength, corrosion resistance, and durability. These essential characteristics are of utmost importance for materials utilized in offshore settings. Incorporating this fiber into various construction materials, like concrete, can significantly enhance their mechanical properties and bolster their resistance against cracking, spalling, and corrosion. Consequently, it is an ideal choice for offshore platform construction, where materials must endure harsh marine conditions, including exposure to saltwater, temperature fluctuations, and strong winds. Moreover, employing stainless steel fiber also contributes to augmenting the structural integrity and lifespan of offshore platforms, thereby reducing long-term maintenance and repair expenses.

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords