Melt Extract Stainless Steel Fiber - Loose Steel Fiber from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-MC

Material: Color Steel

certificated: ISO 9001

Specifications

We manufacture fibers according customer requirement

Steel fiber types includs,

a) Hooked ends steel fiber

b) Wave steel fiber

c) Needle-flat steel fiber

d) Wavy steel fiber

e) Glued steel fiber

f) Micro-steel fiber

g) stainless steel fiber

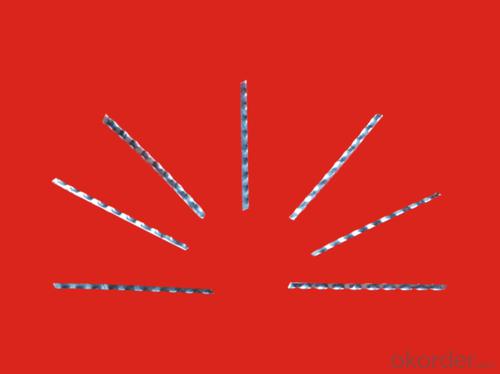

Picture

Steel fiber

Length :30--65 mm

Diameter :0.55--1.0 mm

Tensile strength: >1100 MPA .

Length :25--60 mm

Diameter :0.3--1.2 mm

Tensile strength: >1100 MPA .

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: Can melt extract stainless steel fiber be used in seismic-resistant concrete structures?

- Yes, melt extract stainless steel fiber can be used in seismic-resistant concrete structures. Stainless steel fibers, including melt extract stainless steel fibers, are commonly used as reinforcement in concrete to enhance its tensile strength, ductility, and durability. In seismic-resistant concrete structures, where the concrete is subjected to significant dynamic loads during earthquakes, the inclusion of stainless steel fibers can significantly improve the overall performance and resistance of the structure. The use of melt extract stainless steel fibers in seismic-resistant concrete structures offers several advantages. Firstly, stainless steel fibers have high tensile strength and excellent ductility, which allows them to effectively distribute the applied forces and resist cracking and deformation under seismic loads. This helps to maintain the integrity of the concrete structure and prevent catastrophic failure during earthquakes. Additionally, stainless steel fibers exhibit excellent corrosion resistance, which is crucial in seismic-resistant concrete structures that may be exposed to harsh environmental conditions, such as high moisture or chloride exposure. The corrosion resistance of stainless steel fibers ensures the long-term durability and structural integrity of the concrete, even in aggressive environments. Moreover, melt extract stainless steel fibers also provide enhanced bond strength between the fiber and the concrete matrix. This improves the overall composite behavior of the concrete and enhances its resistance to shear stresses and cracking, which are common during seismic events. Overall, the use of melt extract stainless steel fiber in seismic-resistant concrete structures is a viable and effective solution to enhance their structural performance and durability. It helps to improve the tensile strength, ductility, and corrosion resistance of the concrete, ensuring its ability to withstand the dynamic forces and deformations associated with earthquakes.

- Q: Can melt extract stainless steel fiber improve the resistance of concrete to impact loads?

- Yes, melt extract stainless steel fiber can improve the resistance of concrete to impact loads. Stainless steel fibers are known for their high tensile strength, durability, and ability to enhance the mechanical properties of concrete. When added to concrete mixtures, stainless steel fibers can help to distribute the applied load more evenly and prevent crack propagation, which in turn improves the resistance of concrete to impact loads. The fibers act as reinforcement within the concrete matrix, effectively increasing its resistance to impact and enhancing its overall toughness. Additionally, melt extract stainless steel fibers have a high melting point, which allows them to maintain their structural integrity even under extreme temperatures or rapid heating. This further contributes to the improved impact resistance of concrete. Overall, the addition of melt extract stainless steel fibers can significantly enhance the ability of concrete to withstand impact loads and improve its overall performance in applications where impact resistance is critical, such as industrial floors, pavements, and high-traffic areas.

- Q: How does melt extract stainless steel fiber enhance the impact resistance of concrete?

- The impact resistance of concrete is enhanced by the addition of melt extract stainless steel fiber, which operates through various mechanisms. Firstly, the inclusion of stainless steel fibers in concrete increases its tensile strength, leading to improved resistance against cracking and spalling when impacted. These fibers serve as reinforcement, distributing the load more evenly throughout the concrete matrix and thereby reducing stress concentration at any specific point. Moreover, the high aspect ratio of stainless steel fibers enables them to bridge across cracks that may arise under impact, effectively hindering their propagation. This bridging effect not only strengthens the overall structural integrity of the concrete but also prevents the formation of larger cracks that could compromise its impact resistance. Furthermore, the exceptional properties of stainless steel, such as its strength and resistance to corrosion, make it an ideal material for enhancing concrete's impact resistance. Stainless steel fibers are highly durable and can withstand the harsh conditions commonly encountered in concrete structures, including exposure to chemicals, moisture, and temperature fluctuations. Additionally, the random distribution of stainless steel fibers within the concrete mixture creates a three-dimensional network of reinforcement, aiding in the absorption and dissipation of energy upon impact. This ability to absorb energy reduces the force transmitted through the concrete, minimizing the risk of damage or failure under impact loads. In conclusion, the inclusion of melt extract stainless steel fiber significantly enhances the impact resistance of concrete by improving its tensile strength, inhibiting crack propagation, providing durability, and absorbing energy. This reinforcement technique is particularly advantageous in applications where concrete structures are frequently subjected to impact or dynamic loads, such as industrial floors, pavements, bridge decks, and blast-resistant structures.

- Q: C50 steel fiber concrete, the minimum price, who will tell

- Minimum can not be less than 450 yuan, the proposed offer is 480 yuan.

- Q: Can melt extract stainless steel fiber be used in bridge deck applications?

- Yes, melt extract stainless steel fiber can be used in bridge deck applications.

- Q: How does melt extract stainless steel fiber improve the resistance to spalling in shotcrete?

- Melt extract stainless steel fiber enhances the resistance to spalling in shotcrete by reinforcing the concrete matrix. The fibers are dispersed uniformly throughout the shotcrete, creating a three-dimensional network that improves the overall strength and durability of the material. This reinforcement reduces the formation and propagation of cracks, thereby minimizing the risk of spalling under various loading conditions. Additionally, the stainless steel fibers act as a barrier to inhibit the ingress of moisture and other aggressive substances that can contribute to spalling.

- Q: What is the effect of melt extract stainless steel fiber on the corrosion resistance of concrete?

- The addition of melt extract stainless steel fiber to concrete can significantly enhance its corrosion resistance. Stainless steel fibers are made from a corrosion-resistant alloy, typically containing chromium, nickel, and other elements. When incorporated into concrete, these fibers create a three-dimensional reinforcement system that helps to mitigate the effects of corrosion. Concrete is susceptible to corrosion when exposed to harsh environments, such as chloride-rich or acidic conditions. These corrosive agents can penetrate the concrete and attack the reinforcing steel, leading to structural deterioration and reduced service life. However, the presence of stainless steel fibers in the concrete matrix acts as a barrier, preventing the ingress of corrosive agents and reducing the risk of corrosion. The high corrosion resistance of stainless steel fibers ensures that they remain intact and effective for an extended period. Unlike traditional steel reinforcements, stainless steel fibers do not corrode easily, even under aggressive conditions. This property helps to maintain the integrity of the concrete, providing long-term durability and reducing the need for costly repairs or replacements. Furthermore, the addition of stainless steel fibers also improves the mechanical properties of concrete, such as its tensile strength and crack resistance. This additional reinforcement helps to prevent the formation and propagation of cracks, which can act as pathways for corrosive agents to reach the reinforcing steel. In summary, the incorporation of melt extract stainless steel fiber in concrete enhances its corrosion resistance by acting as a barrier against corrosive agents and improving the overall durability of the structure. This results in a longer service life and reduced maintenance costs for concrete structures exposed to corrosive environments.

- Q: What is the recommended testing procedure for melt extract stainless steel fiber in concrete?

- The recommended testing procedure for melt extract stainless steel fiber in concrete typically involves conducting a series of tests to evaluate its performance and compatibility. This may include evaluating the fiber's physical properties, such as diameter, length, and aspect ratio, through microscopic analysis. Additionally, assessing the fiber's tensile strength, corrosion resistance, and bond strength with concrete is crucial. Various standardized tests, such as ASTM C1550 and ASTM C1609, can be employed to determine these characteristics. Lastly, it is important to conduct field trials to observe the fiber's performance in real-world conditions and ensure its suitability for the intended application.

- Q: Can melt extract stainless steel fiber be added to cementitious grouts?

- Yes, melt extract stainless steel fiber can be added to cementitious grouts. Stainless steel fibers are commonly used as a reinforcement material to enhance the mechanical properties of cementitious products. When added to grouts, stainless steel fibers can improve the tensile strength, flexural strength, and crack resistance of the grout. The addition of stainless steel fibers also helps to control shrinkage and prevent cracking. Overall, incorporating melt extract stainless steel fibers into cementitious grouts can enhance their performance and durability.

- Q: What is the effect of melt extract stainless steel fiber on the flexural toughness of shotcrete?

- The incorporation of melt extract stainless steel fiber in shotcrete has a significant positive effect on the flexural toughness of the material. Stainless steel fibers are specifically designed to enhance the mechanical properties of shotcrete, including its flexural strength and toughness. The addition of melt extract stainless steel fiber to shotcrete improves its resistance to cracking and enhances its ability to withstand bending forces. This is particularly beneficial in applications where shotcrete is subjected to high tensile stresses, such as in underground mining operations, tunnel construction, and slope stabilization. The unique properties of stainless steel, including its high tensile strength, corrosion resistance, and ductility, contribute to the improved flexural toughness of shotcrete. The fibers act as reinforcement within the concrete matrix, effectively bridging any cracks that may occur and distributing the applied loads more evenly. By enhancing the flexural toughness of shotcrete, the incorporation of melt extract stainless steel fiber allows for greater structural integrity and durability. This results in an increased ability of shotcrete structures to withstand external forces, such as seismic activity or ground movements. Furthermore, the improved flexural toughness provided by stainless steel fibers can also lead to a reduction in maintenance and repair costs. The increased resistance to cracking and enhanced durability of shotcrete means that structures will have a longer service life and require fewer interventions. In summary, the effect of melt extract stainless steel fiber on the flexural toughness of shotcrete is highly beneficial. It improves the material's ability to resist cracking and withstand bending forces, leading to increased structural integrity and durability. The incorporation of stainless steel fibers not only enhances the performance of shotcrete but also reduces maintenance and repair costs in the long run.

Send your message to us

Melt Extract Stainless Steel Fiber - Loose Steel Fiber from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords