Melt Extract Stainless Steel Fiber Loose Company from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Place of Origin: China (Mainland)

Model Number: HT-MC

Material: Color Steel

certificated: ISO 9001

Specifications

| Product | Diameter | Length mm/in | Aspect Ratio | Type | Packing |

| G-6030 | 0.5 mm (0.0197 in) | 30 mm (1.1811 in) | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 mm (0.0217 in) | 35 mm (1.3780 in) | 65 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 mm (0.0236 in) | 35 mm (1.3780 in) | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 mm (0.0295 in) | 60 mm (2.3622 in) | 80 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 mm (0.0354 in) | 60 mm (2.3622 in) | 60 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6030 | 0.5 mm (0.0197 in) | 30 mm (1.1811 in) | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 mm (0.0217 in) | 35 mm (1.3780 in) | 65 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 mm (0.0236 in) | 35 mm (1.3780 in) | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 mm (0.0295 in) | 60 mm (2.3622 in) | 80 | Loose | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 mm (0.0354 in) | 60 mm (2.3622 in) | 60 | Loose | 20 kg/Bag, 50 bags/Pallet |

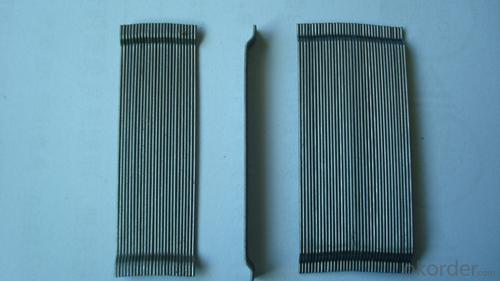

Picture

steel fiber

FAQ

1) Material: low carbon steel wire

2) Diameter: 0.4mm

3) Length: 18mm-35mm

4) Tensile strength: >1000Mpa

5) Feature: excellent tensile, high tenacity, against cracking, impact and fatigue

6) Uses: highway road surface, tunnel, building, airport road surface and so on.

- Q: Can melt extract stainless steel fiber improve the fatigue resistance of concrete?

- Yes, melt extract stainless steel fiber can improve the fatigue resistance of concrete. Stainless steel fibers are commonly used as reinforcement in concrete to enhance its mechanical properties and durability. The addition of stainless steel fibers improves the cracking and fatigue resistance of concrete by reinforcing the matrix and increasing its ability to withstand cyclic loading and stress. These fibers act as reinforcement by bridging cracks and preventing their propagation, thereby improving the overall fatigue performance of concrete. Melt extract stainless steel fibers have high tensile strength and excellent corrosion resistance, making them especially effective in enhancing the fatigue resistance of concrete structures.

- Q: What is the effect of melt extract stainless steel fiber on the flexural toughness of concrete?

- The addition of melt extract stainless steel fiber to concrete has a positive effect on the flexural toughness of the material. The fibers act as reinforcement, increasing the overall strength and resistance to cracking or failure under bending or flexural forces. This leads to improved durability and increased load-bearing capacity of the concrete, making it more suitable for applications where flexural strength is crucial.

- Q: Steel fiber concrete structure and steel reinforced concrete structure belong to concrete mix structure?

- Steel fiber reinforced concrete is a new kind of multiphase composite material, which is made up of short steel fiber reinforced by random distribution in ordinary concrete.SRC structure according to the code for design of SRC structures (YB9082-97), the steel content is greater than 2%, less than 15%.SRC structure still belongs to the category of reinforced concrete structure.Steel fiber reinforced concrete structure is still a kind of masonry structure.

- Q: Is melt extract stainless steel fiber compatible with various types of cement?

- Yes, melt extract stainless steel fiber is compatible with various types of cement.

- Q: Can melt extract stainless steel fiber be used in fiber-reinforced polymers?

- Yes, melt extract stainless steel fiber can be used in fiber-reinforced polymers (FRPs). Stainless steel fibers are often added to polymer matrices to enhance their mechanical properties such as tensile strength, flexural strength, and impact resistance. The melt extract stainless steel fibers are obtained through a specialized process that ensures uniformity and high quality. The addition of stainless steel fibers to FRPs can provide several benefits. Firstly, the fibers can enhance the overall strength and durability of the composite material, making it suitable for applications that require high strength-to-weight ratio. Secondly, stainless steel fibers can improve the fracture toughness of the FRPs, making them more resistant to crack propagation. This can be particularly important in applications where impact resistance is crucial. Additionally, the corrosion resistance of stainless steel fibers can be advantageous in environments where the FRPs may be exposed to harsh conditions, such as moisture, chemicals, or high temperatures. The stainless steel fibers can prevent corrosion of the composite material, increasing its lifespan and reliability. Overall, the use of melt extract stainless steel fibers in fiber-reinforced polymers can significantly enhance the mechanical properties and durability of the composite material, making it suitable for a wide range of applications in industries such as automotive, construction, aerospace, and marine.

- Q: How does melt extract stainless steel fiber affect the carbonation resistance of concrete?

- Melt extract stainless steel fiber can significantly enhance the carbonation resistance of concrete. Carbonation is a chemical process where carbon dioxide from the atmosphere reacts with the calcium hydroxide in concrete to form calcium carbonate. This process can lead to a reduction in the alkalinity of the concrete, which in turn can result in the corrosion of embedded reinforcement and a decrease in the overall durability of the structure. By incorporating melt extract stainless steel fiber into concrete, it creates a three-dimensional reinforcement network that helps to improve the mechanical properties and durability of the concrete. The stainless steel fibers act as a physical barrier, reducing the ingress of carbon dioxide into the concrete matrix. This barrier effect slows down the carbonation process, effectively increasing the carbonation resistance of the concrete. Additionally, the stainless steel fibers also enhance the overall mechanical properties of the concrete, making it more resistant to cracking and spalling. This increased resistance to cracking further reduces the potential for carbon dioxide to penetrate the concrete, as cracks provide pathways for gas diffusion. Furthermore, the stainless steel fibers can also help to mitigate the effects of carbonation by providing an additional level of corrosion protection to the embedded reinforcement. The fibers act as sacrificial anodes, diverting any potential corrosion initiation sites away from the reinforcement and onto themselves. This sacrificial anode effect helps to prolong the service life of the concrete structure by reducing the risk of reinforcement corrosion due to carbonation. In summary, melt extract stainless steel fiber positively affects the carbonation resistance of concrete by acting as a physical barrier, enhancing mechanical properties, and providing additional corrosion protection to the embedded reinforcement. These benefits contribute to increased durability and extended service life of concrete structures in carbonation-prone environments.

- Q: What is the typical length of melt extract stainless steel fiber?

- The typical length of melt extract stainless steel fiber varies depending on the specific application and manufacturer. However, in general, melt extract stainless steel fibers are available in lengths ranging from 3 mm to 50 mm or even longer. The length of the fiber is usually determined by factors such as the desired strength and reinforcement properties, as well as the specific requirements of the application. It is important to consult with the manufacturer or supplier to determine the most suitable length of melt extract stainless steel fiber for your particular needs.

- Q: Can melt extract stainless steel fiber be used in asphalt reinforcement?

- Yes, melt extract stainless steel fiber can be used in asphalt reinforcement. Stainless steel fibers are often added to asphalt mixtures to enhance their mechanical properties and improve their resistance to cracking and fatigue. These fibers are typically melt-extracted from stainless steel materials, resulting in a high-strength and corrosion-resistant reinforcing element. When added to asphalt, stainless steel fibers can increase the tensile strength, flexibility, and durability of the pavement, making it more resistant to rutting, cracking, and other forms of distress. Additionally, the use of stainless steel fibers can also improve the overall lifespan of the asphalt pavement by reducing maintenance and repair needs. Therefore, melt extract stainless steel fiber is a suitable option for asphalt reinforcement and can provide numerous benefits in terms of performance and longevity.

- Q: Can melt extract stainless steel fiber be used in concrete bridge decks?

- Yes, melt extract stainless steel fiber can be used in concrete bridge decks. Stainless steel fibers are commonly used as reinforcement in concrete structures, including bridge decks. These fibers improve the overall strength and durability of the concrete, enhancing its resistance to cracking and increasing its load-bearing capacity. Melt extract stainless steel fibers are known for their high tensile strength and corrosion resistance, making them an excellent choice for bridge decks exposed to harsh environmental conditions. Additionally, these fibers can help control shrinkage and prevent the formation of cracks, enhancing the long-term performance and service life of the bridge decks. Overall, melt extract stainless steel fiber is a suitable and beneficial reinforcement option for concrete bridge decks.

- Q: How does melt extract stainless steel fiber enhance the crack resistance of concrete?

- The crack resistance of concrete is enhanced by melt extract stainless steel fiber through various mechanisms. Firstly, the inclusion of stainless steel fibers in the concrete mix augments its tensile strength. As a result, the concrete becomes more capable of withstanding forces that lead to cracking, such as shrinkage, temperature fluctuations, and external loads. The fibers assist in distributing these forces uniformly across the concrete, thereby diminishing the probability of crack formation. Secondly, stainless steel fibers act as reinforcement within the concrete matrix. In the event of cracks, the fibers help hold the concrete together and hinder the propagation of cracks. This contributes to the overall durability and longevity of the concrete structure. Moreover, melt extract stainless steel fibers also improve the impact resistance of concrete. They absorb and disperse energy from impacts, decreasing the likelihood of crack formation or propagation caused by sudden loading. Furthermore, stainless steel fibers can enhance the concrete's resistance to chemical attack. They serve as a physical barrier that impedes the penetration of aggressive chemicals, such as chlorides or sulfates, into the concrete. This safeguards the concrete against deterioration and reduces the risk of crack formation due to chemical exposure. In conclusion, melt extract stainless steel fiber enhances the crack resistance of concrete by boosting its tensile strength, reinforcing the concrete matrix, increasing its impact resistance, and providing a barrier against chemical attack. These combined effects result in a more durable and crack-resistant concrete structure.

Send your message to us

Melt Extract Stainless Steel Fiber Loose Company from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords