Melt Extract Stainless Steel Fiber 430

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

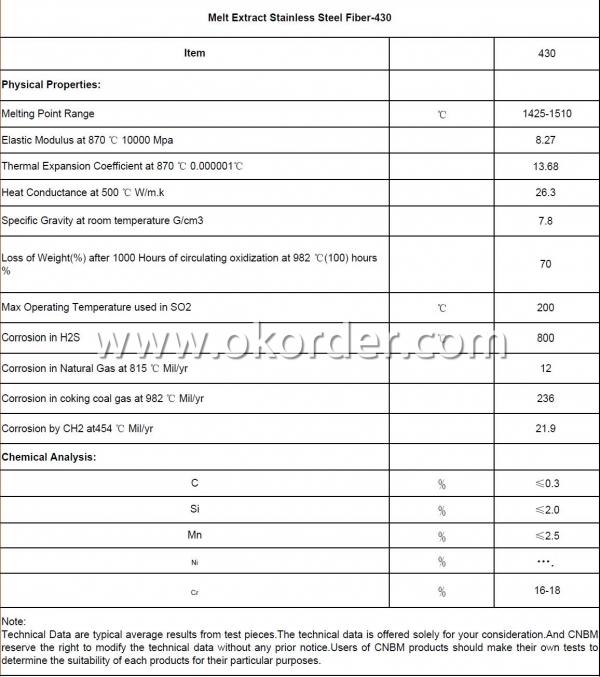

General Information of Melt Extract Stainless Steel Fiber 430

CMAX melt extract stainless steel fibers not only allow for more user-friendly than the stiff cut fibers ,but also have better flow features.Melt extract stainless steel fiber is produced by melting elements in a crucible. A flywheel is then introduced to the crucible and droplets of molten metal are spun into the open air and hardened.The speed of the wheel determines the fiber length. CMAX melt extract stainless steel fiber can increase the lifetime of refractory materials and industrial furnaces by several times, decreasing cost. It has outstanding performances in thermal shock resistance.

Feature of CMAX Melt Extract Stainless Steel Fiber 430

Improve refractories’performance

Improve refractories’longevity

Improve refractories’durability

Significantly reducing downtime and maintance cost

Application of CMAX Melt Extract Stainless Steel Fiber 430

Refractory products

Precast

Castable project

Industrial furnaces

Other refractories project

Our company has success in its melt extract stainless steel fibe rproducts due to their cost-effectiveness and excellent insulating properties. We also have experience in melt extract stainless steel fiber application and would like to assist you in product selection, system design, and installation techniques. Our products of melt extract stainless steel fiber are in good quality and in best price. We can serve many products in your satisfaction.

- Q: Does melt extract stainless steel fiber improve the resistance to freeze-thaw cycles of concrete?

- Yes, melt extract stainless steel fiber does improve the resistance to freeze-thaw cycles of concrete. The addition of stainless steel fibers in concrete helps to enhance its durability and performance by minimizing the detrimental effects of freeze-thaw cycles. When water freezes within the concrete, it expands and exerts pressure on the surrounding matrix, leading to cracking and eventual deterioration of the structure. However, the inclusion of melt extract stainless steel fibers helps to mitigate these issues. The fibers act as reinforcement within the concrete, providing additional strength and preventing the propagation of cracks. This reinforcement effectively enhances the resistance of the concrete to the damaging effects of freeze-thaw cycles. Moreover, melt extract stainless steel fibers have excellent corrosion resistance properties, which further contribute to the improved durability of the concrete. Unlike other types of fibers, stainless steel fibers do not corrode or degrade over time, ensuring their long-term effectiveness in enhancing freeze-thaw resistance. Overall, the addition of melt extract stainless steel fiber in concrete significantly improves its resistance to freeze-thaw cycles, preventing cracking and extending the lifespan of the structure.

- Q: Can melt extract stainless steel fiber be used in lightweight shotcrete applications?

- Melt extract stainless steel fiber is a viable option for lightweight shotcrete applications. Adding stainless steel fibers to shotcrete mixes has proven to enhance the overall strength, durability, and crack resistance of the concrete. By incorporating stainless steel fibers, the flexural and tensile strength of the shotcrete can be significantly improved, which is particularly important for lightweight applications that require strong structural integrity. Moreover, stainless steel fibers also contribute to reducing shrinkage and thermal cracking, making them a suitable choice for lightweight shotcrete applications. However, it is crucial to carefully consider the specific requirements and specifications of the project and seek guidance from a structural engineer or shotcrete expert to ensure the appropriate fiber content and mix design for a successful application.

- Q: What is the recommended dosage of melt extract stainless steel fiber in concrete mixtures?

- The dosage of melt extract stainless steel fiber in concrete mixtures can vary depending on the specific application and desired outcome. Typically, the dosage ranges from 20 to 40 kilograms per cubic meter (kg/m³) of concrete. However, it is essential to seek advice from the manufacturer or a structural engineer to determine the optimal dosage for a particular project. Several factors can influence the dosage, including the intended use of the concrete (such as industrial flooring, precast elements, or shotcrete), the required level of reinforcement, and the desired properties of the stainless steel fiber, such as enhanced crack resistance, impact resistance, or durability. Furthermore, it is important to note that the length and diameter of the stainless steel fibers can impact the dosage. Longer and thicker fibers generally require a lower dosage to achieve the desired reinforcement effect. Ultimately, consulting with professionals and considering the specific requirements and objectives of the project is crucial in determining the most suitable dosage of melt extract stainless steel fiber in concrete mixtures.

- Q: Can melt extract stainless steel fiber be used in railway sleepers?

- Certainly, melt extract stainless steel fiber is applicable for utilization in railway sleepers. Known for its exceptional resistance to corrosion and fatigue, stainless steel fiber serves as a robust material. By incorporating it into railway sleepers, the overall strength and longevity of the sleepers are significantly enhanced, rendering them suitable for heavy train loads and extended service life. The melt extract process guarantees the uniform and consistent shape of the stainless steel fibers, thereby further augmenting their performance and dependability. Moreover, the utilization of stainless steel fiber aids in the prevention of crack formation and improves resistance to thermal expansion and contraction, making it an ideal selection for railway sleepers.

- Q: How does melt extract stainless steel fiber affect the cracking behavior of concrete?

- Melt extract stainless steel fiber has a significant impact on the cracking behavior of concrete. These fibers, which are produced by melting stainless steel and then extracting it into fibers of varying lengths, are commonly used as reinforcement in concrete structures. One of the main benefits of using melt extract stainless steel fiber is its ability to enhance the crack resistance of concrete. When added to the concrete mix, these fibers act as a reinforcement, providing additional strength and preventing the propagation of cracks. This is particularly important in concrete structures that are subjected to heavy loads or dynamic forces, as they are more prone to crack formation. The presence of stainless steel fibers in concrete improves its tensile strength, which is typically much lower than its compressive strength. As a result, the concrete becomes more resistant to cracking, as the fibers help distribute the stress and prevent the formation and propagation of cracks. This enhanced crack resistance is especially beneficial in applications where concrete is subjected to shrinkage, thermal expansion, or external loading, as it helps maintain the integrity and durability of the structure. Moreover, melt extract stainless steel fibers also improve the post-cracking behavior of concrete. In conventional concrete, once a crack forms, it tends to propagate rapidly, compromising the structural integrity and reducing its load-bearing capacity. However, with the addition of stainless steel fibers, these cracks are effectively bridged and restrained, reducing their width and preventing further propagation. This post-cracking behavior is crucial in maintaining the structural performance and serviceability of the concrete under various loading conditions. In summary, melt extract stainless steel fiber significantly influences the cracking behavior of concrete by enhancing its crack resistance, tensile strength, and post-cracking behavior. By reinforcing the concrete matrix, these fibers prevent crack formation and propagation, improving the durability and structural integrity of concrete structures.

- Q: How does melt extract stainless steel fiber affect the modulus of elasticity of concrete?

- By incorporating melt extract stainless steel fiber into concrete, a significant impact can be observed on the modulus of elasticity. These fibers, when introduced to the concrete mixture, boost the overall strength and stiffness of the material. The superior tensile strength and rigidity of stainless steel fibers aid in the uniform distribution of stress throughout the concrete matrix. Consequently, this leads to an improvement in the load-bearing capacity of the concrete and a reduction in cracking. The addition of melt extract stainless steel fiber reinforces the concrete by increasing its modulus of elasticity and bridging any possible microcracks. Consequently, the propagation of cracks is prevented, ultimately enhancing the durability and structural integrity of the concrete. Furthermore, the stainless steel fibers function as a reinforcement mechanism, ensuring the concrete's integrity even under extreme conditions like high temperatures or dynamic loading. The elevated modulus of elasticity provided by these fibers enables the concrete to better withstand external forces and deformations, thereby minimizing the risk of failure. To summarize, the inclusion of melt extract stainless steel fiber has a positive influence on the modulus of elasticity of concrete. This is achieved by strengthening the material, improving its load-bearing capacity, reducing cracking, and enhancing its resistance to various environmental and mechanical stresses.

- Q: Is melt extract stainless steel fiber suitable for use in tunnel lining construction?

- Yes, melt extract stainless steel fiber is suitable for use in tunnel lining construction. It provides enhanced strength, durability, and resistance to corrosion, making it an ideal choice for reinforcing concrete in tunnels.

- Q: Does melt extract stainless steel fiber enhance the flexural toughness of concrete beams?

- Yes, melt extract stainless steel fiber does enhance the flexural toughness of concrete beams. The addition of these fibers improves the resistance of the concrete to cracking, increasing its ability to withstand bending and flexural loads.

- Q: Can melt extract stainless steel fiber be used in architectural precast panels?

- Architectural precast panels can indeed utilize melt extract stainless steel fiber. These fibers are commonly incorporated into the concrete mixture during production to bolster the panels' mechanical characteristics. By enhancing the tensile strength, flexural strength, and durability of the panels, the stainless steel fibers effectively heighten their resistance to cracking and overall performance. Furthermore, the inclusion of stainless steel fibers can also lessen the panels' weight, simplifying their handling and installation. Consequently, melt extract stainless steel fiber proves to be a fitting choice for reinforcing architectural precast panels.

- Q: Can melt extract stainless steel fiber be used in the construction of offshore platforms?

- Yes, melt extract stainless steel fiber can be used in the construction of offshore platforms. It is a durable and corrosion-resistant material that can enhance the strength and integrity of the structure, making it suitable for harsh marine environments.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 200 Million |

| Main Markets | North America;Asia;Western Europe;Africa;Russia;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Installation guide, OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Melt Extract Stainless Steel Fiber 430

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords