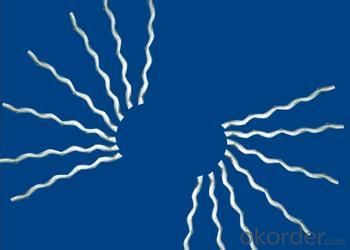

Melt Extract Stainless Steel Fiber End Hook Glued Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Place of Origin: Tianjin, China (Mainland)

Model Number: 0.50 mm

Material: Steel

Production Process: Cold drawn

Lengh: 35

Type: 1

Compressive Strength: >1200MPa

Aspect ratio: 70

Standard: ASTM A820M-11

Section Shape: Circular

Application: Concrete Reinforcement

Packaging & Delivery

| Packaging Details: | 20 kg/Bag,50 bags/Pallet or 1,000kg/ Bulk Bag |

|---|---|

| Delivery Detail: | 1 Month |

Product Description

| Diameter | 0.50 mm | ||

| Length | 35 mm | ||

| Aspect Ratio | 70 | ||

| Tensile strength | 1200 MPa | ||

| Type | Cold drawn Steel Fiber | ||

| End | Hooked-end Steel Fiber | ||

| Glued/Loose | Glued Steel Fiber | ||

| Bending Angle | 45°(min.30°) | ||

| Usage & Performance | Floor:Trafficked areas and Industrial floors | ||

| Shotcrete :Slope stabilization and Final lining | |||

| Precast concrete:Pipe and Railway sleepers | |||

| Packing | Standard Export Pallet Packing | Bag Packing | 20 kg/Bag,50 bags/Pallet |

| Bulk Packing | 1,000kg/ Bulk Bag | ||

| Loading Quantity | 20’GP | 20-25 Tonne/Tonnes | |

| 40’GP | 25-27 Tonne/Tonnes | ||

| 40’HQ | 25-27 Tonne/Tonnes | ||

| MOQ | 1 kg for trial order | ||

| Supply Ability | 10,000 Tonne/Tonnes per Year | ||

| Payment Terms | T/T or L/C at sight | ||

| Delivery Time | Within 15 days after receiving deposit or original L/C at sight | ||

| Certification | ISO9001:2000, CE, | ||

| Product | Diameter (mm) | Length (mm) | Aspect Ratio | Type | Packing |

| G-6030 | 0.5 | 30 | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 | 35 | 65 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 | 35 | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 | 60 | 80 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 | 60 | 60 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6030 | 0.5 | 30 | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 | 35 | 65 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 | 35 | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 | 60 | 80 | Loose | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 | 60 | 60 | Loose | 20 kg/Bag, 50 bags/Pallet |

- Q: Can melt extract stainless steel fiber be used in architectural precast elements?

- Yes, melt extract stainless steel fiber can be used in architectural precast elements.

- Q: Are there any specific mixing requirements for concrete with melt extract stainless steel fiber?

- Concrete with melt extract stainless steel fiber has specific mixing requirements. Achieving the desired performance and properties requires ensuring proper dispersion and distribution of the fibers. To incorporate stainless steel fiber into the concrete, it is necessary to add them during the mixing process. Using a high-performance mixer is recommended to ensure even distribution throughout the mixture. Adding the fibers slowly and continuously is important to prevent clumping and ensure thorough integration. The mixing time needs to be extended to ensure proper fiber dispersion. The recommended mixing time depends on the type and length of the stainless steel fiber and the desired concrete properties. Generally, a longer mixing time is necessary compared to conventional concrete mixes for good fiber distribution. It is crucial to avoid excessive mixing as it can cause fiber breakage and reduce effectiveness. Following the manufacturer's guidelines and recommendations regarding specific mixing requirements for the stainless steel fiber is essential. Furthermore, adjusting the concrete mix design may be necessary to accommodate the addition of stainless steel fibers. Modifying the water-cement ratio, aggregate grading, and other mix proportions can achieve the desired workability and performance. In conclusion, proper mixing is vital for concrete with melt extract stainless steel fiber to ensure uniform distribution and maximize the benefits of adding the fibers. These benefits include enhanced tensile strength, crack resistance, and durability. Consulting with the manufacturer or a qualified engineer is recommended to determine the specific mixing requirements for the stainless steel fiber used in your concrete mix.

- Q: How does melt extract stainless steel fiber improve the resistance of concrete to chloride ingress?

- Melt extract stainless steel fiber plays a crucial role in enhancing the resistance of concrete to chloride ingress. When added to the concrete mixture, these stainless steel fibers provide a physical barrier that impedes the movement of chloride ions into the concrete matrix. Chloride ions are a leading cause of corrosion in reinforced concrete structures, as they penetrate the concrete and reach the steel reinforcement, leading to its corrosion and eventual degradation. This corrosion not only compromises the structural integrity of the concrete but also reduces its service life. The presence of melt extract stainless steel fibers in the concrete effectively reduces the permeability of the material, limiting the ingress of chloride ions. These fibers create a network within the concrete, forming a three-dimensional reinforcement system that restricts the movement of chloride ions. Additionally, the stainless steel fibers enhance the mechanical properties of the concrete, making it more resistant to cracking and spalling caused by chloride-induced corrosion. They improve the tensile and flexural strength of the concrete, minimizing the potential for crack formation and propagation. Furthermore, melt extract stainless steel fibers also act as a sacrificial anode, preventing the corrosion of the steel reinforcement. As the chloride ions come into contact with the stainless steel fibers, they are attracted to the fibers instead of the reinforcement, reducing the risk of corrosion. In summary, melt extract stainless steel fibers improve the resistance of concrete to chloride ingress by creating a physical barrier, reducing permeability, enhancing mechanical properties, and acting as a sacrificial anode. These fibers significantly extend the service life of concrete structures by mitigating the detrimental effects of chloride-induced corrosion.

- Q: Does melt extract stainless steel fiber improve the resistance to sulfate attack of concrete?

- Concrete can be susceptible to sulfate attack, which can cause deterioration and reduced durability. However, the use of melt extract stainless steel fiber can enhance the resistance to sulfate attack. This is because stainless steel is corrosion-resistant and acts as reinforcement to strengthen and increase the durability of the concrete. Furthermore, the inclusion of stainless steel fibers can prevent the formation of cracks, thereby reducing the risk of sulfate ions penetrating the concrete and causing harm. In conclusion, incorporating melt extract stainless steel fibers into concrete structures can greatly enhance their resistance to sulfate attack.

- Q: What is the effect of melt extract stainless steel fiber on the modulus of elasticity of shotcrete?

- The incorporation of melt extract stainless steel fiber into shotcrete results in an augmentation of the material's modulus of elasticity, ultimately leading to an overall increase in stiffness and rigidity. This addition of stainless steel fibers aids in the enhancement of shotcrete's mechanical properties, including its modulus of elasticity. Stainless steel fibers possess notable tensile strength and exceptional corrosion resistance. When integrated into shotcrete, they establish a reinforcement network throughout the material, bolstering its capacity to withstand external forces and stresses. The modulus of elasticity quantifies a material's ability to deform when subjected to a load and subsequently return to its original shape after the load is removed. By introducing melt extract stainless steel fibers into shotcrete, the overall modulus of elasticity is elevated, rendering the shotcrete more resistant to deformation and imbuing it with heightened stiffness, thereby reducing its susceptibility to cracking and enhancing its structural integrity. Moreover, the inclusion of stainless steel fibers can also aid in the management and mitigation of shrinkage cracking in shotcrete, which is particularly crucial in applications where shotcrete functions as a structural element or serves as a lining material in underground constructions such as tunnels or mines. To summarize, the effect of melt extract stainless steel fiber on the modulus of elasticity of shotcrete is a substantial increase in stiffness and rigidity. This improvement in mechanical properties instills shotcrete with enhanced durability, diminished cracking, and improved structural performance across diverse construction settings.

- Q: What is the effect of melt extract stainless steel fiber on the crack width in shotcrete?

- The use of melt extract stainless steel fiber in shotcrete can effectively reduce crack width by enhancing the tensile strength and ductility of the material. The fibers act as reinforcement, distributing the stress more evenly, and preventing the propagation of cracks. This results in improved crack resistance and overall durability of the shotcrete structure.

- Q: Can melt extract stainless steel fiber be used in cooling tower construction?

- Yes, melt extract stainless steel fiber can be used in cooling tower construction.

- Q: What is the effect of melt extract stainless steel fiber on the curing time of concrete?

- The inclusion of melt extract stainless steel fiber in concrete can have a significant effect on the curing time of the material. Stainless steel fibers are typically added to concrete mixtures to enhance its mechanical properties, such as its strength, durability, and crack resistance. The presence of stainless steel fibers in concrete affects the curing time primarily by improving the bond between the cement matrix and the aggregate. This enhanced bond increases the rate of hydration, which is the chemical reaction that occurs between the cement and water, resulting in the hardening of concrete. Due to the improved hydration process, concrete containing melt extract stainless steel fibers generally experiences faster initial setting and strength development. This means that the concrete can reach an adequate level of hardness and strength more quickly compared to plain concrete without fibers. As a result, the overall curing time of the concrete is reduced. Additionally, the use of stainless steel fibers can also minimize plastic shrinkage cracking, which occurs during the early stages of concrete curing when the water content evaporates faster than the hydration reaction takes place. By reducing these cracks, the curing time can be further accelerated as there is less need for repair or remediation. However, it is important to note that the specific effect of melt extract stainless steel fiber on curing time can vary depending on various factors, such as the dosage of fibers, aggregate type, environmental conditions, and the overall concrete mixture design. Therefore, it is crucial to conduct thorough testing and analysis to determine the exact impact of stainless steel fibers on the curing time of concrete in a particular application.

- Q: What is the effect of melt extract stainless steel fiber on the flexural toughness of shotcrete?

- The effect of melt extract stainless steel fiber on the flexural toughness of shotcrete is an increase in the overall toughness and crack resistance of the material. The stainless steel fibers reinforce the shotcrete, preventing the propagation of cracks and enhancing its ability to withstand bending and flexural stresses. This results in improved durability and structural integrity of the shotcrete, making it more suitable for applications where flexural toughness is important, such as tunnel linings or retaining walls.

- Q: Does melt extract stainless steel fiber improve the resistance to sulfate attack of shotcrete?

- Yes, melt extract stainless steel fiber does improve the resistance to sulfate attack of shotcrete.

Send your message to us

Melt Extract Stainless Steel Fiber End Hook Glued Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords