Melt Extract Stainless Steel Fiber - Steel Fiber Loose Company CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Tianjin, China (Mainland)

Brand Name: CNBM

Model Number: 0.55

Material: Steel

Production Process: Cold drawn

Fiber Lengh: 35

Type: 1

Compressive Strength: >1200MPa

Aspect ratio: 63

Standard: ASTM A820M-11

Section Shape: Circular

Application: Concrete Reinforcement

Producing Area: Tianjin

Product Application: Industrial Floor

Specifications

| Diameter | 0.55 mm (0.217 in) | ||

| Length | 35 mm (13.780 in) | ||

| Aspect Ratio | 63 | ||

| Tensile strength | 1200 MPa | ||

| Type | Cold drawn Steel Fiber | ||

| End | Hooked-end Steel Fiber | ||

| Glued/Loose | Glued Steel Fiber | ||

| Bending Angle | 45°(min.30°) | ||

| Usage & Performance | Floor:Trafficked areas and Industrial floors | ||

| Shotcrete :Slope stabilization and Final lining | |||

| Precast concrete:Pipe and Railway sleepers | |||

| Packing | Standard Export Pallet Packing | Bag Packing | 20 kg/Bag,50 bags/Pallet |

| Bulk Packing | 1,000kg/ Bulk Bag | ||

| Loading Quantity | 20’GP | 20-25 Tonne/Tonnes | |

| 40’GP | 25-27 Tonne/Tonnes | ||

| 40’HQ | 25-27 Tonne/Tonnes | ||

| MOQ | 1 kg for trial order | ||

| Supply Ability | 10,000 Tonne/Tonnes per Year | ||

| Payment Terms | T/T or L/C at sight | ||

| Delivery Time | Within 15 days after receiving deposit or original L/C at sight | ||

| Certification | ISO9001:2000, CE, | ||

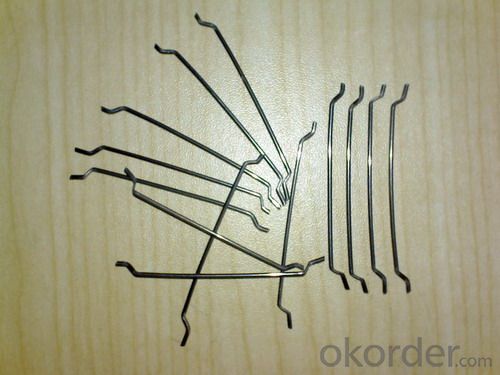

Picture

Steel fiber

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: How does melt extract stainless steel fiber improve the resistance to carbonation in concrete?

- Melt extract stainless steel fiber improves the resistance to carbonation in concrete by providing enhanced durability and protection against the carbonation process. When incorporated into the concrete mixture, these stainless steel fibers act as reinforcement, increasing the overall strength and resistance to various deteriorating factors, including carbonation. Carbonation is a chemical process that occurs when carbon dioxide (CO2) from the atmosphere reacts with the calcium hydroxide (Ca(OH)2) present in the concrete, forming calcium carbonate (CaCO3). This reaction reduces the alkalinity of the concrete and weakens its protective layer, leading to potential corrosion of the reinforcing steel. By adding melt extract stainless steel fiber to the concrete, the resistance to carbonation is significantly improved. The stainless steel fibers create a three-dimensional network within the concrete matrix, enhancing its mechanical properties and reducing crack formation. This network also acts as a barrier against the ingress of CO2, limiting the contact between the atmospheric carbon dioxide and the calcium hydroxide. Furthermore, the stainless steel fibers assist in maintaining the alkalinity of the concrete by reducing the penetration of carbon dioxide. The steel fibers also provide an electrochemical protection mechanism by acting as cathodic sites, preventing the corrosion of the reinforcing steel. This cathodic protection is achieved through the formation of a passive oxide layer on the surface of the stainless steel fibers, which resists corrosion and inhibits the carbonation process. Overall, the addition of melt extract stainless steel fiber to concrete improves its resistance to carbonation by enhancing its strength, reducing crack formation, limiting CO2 ingress, maintaining alkalinity, and providing cathodic protection against corrosion. This results in a more durable and long-lasting concrete structure with improved resistance to carbonation-induced deterioration.

- Q: What are the main points of construction of steel fiber reinforced concrete?

- About the construction points of steel fiber reinforced concrete, roughly speaking from the following five aspects:1. steel fiber dispersion deviceFirst, the steel fiber shall be taken into and dispersed. By dispersing device device into a stirrer. By dispersing device can avoid the agglomeration phenomenon. Other materials and engineering should be required in the uniform mixing of steel fiber into a blender.

- Q: What is steel fiber? What's the use of it?

- Concrete made of steel fiber is stronger

- Q: Is melt extract stainless steel fiber compatible with all types of cement?

- No, melt extract stainless steel fiber is not compatible with all types of cement. It is often recommended for use with high-performance concrete or cementitious systems that require improved crack resistance, durability, and flexural strength. However, compatibility may vary depending on the specific composition and characteristics of the cement being used. It is always advisable to consult the manufacturer's guidelines or seek professional advice before using stainless steel fiber with a specific type of cement.

- Q: Is melt extract stainless steel fiber suitable for use in high-performance mortar?

- Yes, melt extract stainless steel fiber is suitable for use in high-performance mortar. It enhances the mechanical properties and durability of the mortar, providing increased flexural and impact strength, as well as improved resistance to cracking, shrinkage, and corrosion.

- Q: Can melt extract stainless steel fiber be used in fiber-reinforced shotcrete applications?

- Yes, melt extract stainless steel fiber can be used in fiber-reinforced shotcrete applications.

- Q: How does melt extract stainless steel fiber improve the resistance to corrosion in concrete?

- Melt extract stainless steel fiber improves the resistance to corrosion in concrete by providing an additional layer of protection. The stainless steel fibers act as a reinforcement, distributing the load and reducing the risk of cracking, which can expose the concrete to moisture and corrosive elements. Additionally, the stainless steel fibers are highly resistant to corrosion themselves, preventing the development of rust and further deterioration of the concrete.

- Q: Can melt extract stainless steel fiber be used in the construction of water storage tanks?

- Melt extract stainless steel fiber is a suitable material for the construction of water storage tanks. Its characteristics include high strength, durability, and corrosion resistance, which make it ideal for storing water. The fiber can endure the challenging conditions and chemicals commonly present in water tanks, guaranteeing prolonged functionality and reducing the chances of leaks or deterioration. Furthermore, the inclusion of stainless steel fiber improves the tank's structural integrity, reinforcing it and preventing cracks or failures. Ultimately, employing melt extract stainless steel fiber in water storage tank construction is a dependable and efficient option.

- Q: Can melt extract stainless steel fiber replace traditional reinforcement in concrete structures?

- Yes, melt extract stainless steel fiber can potentially replace traditional reinforcement in concrete structures. These fibers provide enhanced strength, durability, and crack resistance to the concrete. They also improve the overall performance of the structure by reducing the need for additional reinforcement materials. However, the specific application and structural requirements should be carefully evaluated before making a decision to ensure the suitability and effectiveness of the stainless steel fiber as a replacement for traditional reinforcement.

- Q: Can melt extract stainless steel fiber be used in tunnel shotcreting applications?

- Tunnel shotcreting applications can benefit from the use of melt extract stainless steel fiber. This process involves applying a concrete or mortar mix to the walls of a tunnel or underground structure using a spraying technique. By adding stainless steel fibers to the shotcrete mix, reinforcement is provided, resulting in improved overall performance and durability of the sprayed concrete. Melt extract stainless steel fibers are commonly utilized in shotcrete applications due to their high tensile strength, resistance to corrosion, and ability to enhance the post-cracking behavior of the concrete. These fibers are created by melting stainless steel, rapidly cooling it, and forming fine, elongated fibers. The inclusion of stainless steel fibers in tunnel shotcreting helps prevent crack formation and controls crack propagation, thereby increasing the structural integrity and longevity of the sprayed concrete. These fibers also enhance the shotcrete's resistance to impact, abrasion, and spalling, which are common challenges encountered in tunnel construction. Furthermore, the addition of stainless steel fibers improves the overall performance of the shotcrete by reducing shrinkage and enhancing the bond strength between the shotcrete and the tunnel surface. This is particularly crucial in tunnel shotcreting applications where it is necessary for the sprayed concrete to adhere well to the surrounding rock or soil. To conclude, melt extract stainless steel fiber proves to be an effective addition in tunnel shotcreting applications as it enhances the durability, strength, and performance of the sprayed concrete. Its incorporation helps overcome common challenges in tunnel construction and ultimately improves the quality of the tunnel walls.

Send your message to us

Melt Extract Stainless Steel Fiber - Steel Fiber Loose Company CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords