3003 H14 Aluminum Coil for Building Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium Coil Used for Building Material

l Product Introduction

It is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

1. Temper: O, F, HXX

2. Thickness: Thickness

3. Width: 1000-1500mm

4. Type: Coil/Roll

5. Surface Treatment: mill finished

6. Application: Decoration, packaging, printing, covering

7. Standard size: Upon customer's demand

8. Quantity: 18tons(±10%)in one 20 feet container

l Product Description

Specification:

Aluminium Coil Used for Building Material | ||||||||||||||||

Aluminium Coils, non-alloy and alloy products have many different applications, they are used windly throughout construction, building, decoration, lighting, metal nameplate, aircraft and aerospace structures, etc. | ||||||||||||||||

Specification | ||||||||||||||||

ALLOY | TEMPER | THICKNESS | WIDTH(mm) | LENGTH(mm) | ||||||||||||

1050, 1060, 1070, | O, F, H12, 114, H18, H22, H24, H26, H32, H34, H36, H111, H112, H314 | 3.0-10.0 | 1000--1500mm | in Coil | ||||||||||||

chemical composition | ||||||||||||||||

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Min.Al | |||

1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.50 | |||

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.60 | |||

1070 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | - | 0.05 | 0.03 | 0.03 | 99.70 | |||

1100 | 0.95 | 0.05-0.2 | 0.05 | - | - | - | 0.10 | - | - | - | 0.05 | 99.00 | ||||

3003 | 0.60 | 0.70 | 0.5-0.2 | 1.0-1.5 | - | - | - | 0.10 | - | - | - | 0.15 | 96.95-96.75 | |||

3004 | 0.30 | 0.70 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | - | - | - | 0.15 | 96.55-95.55 | |||

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

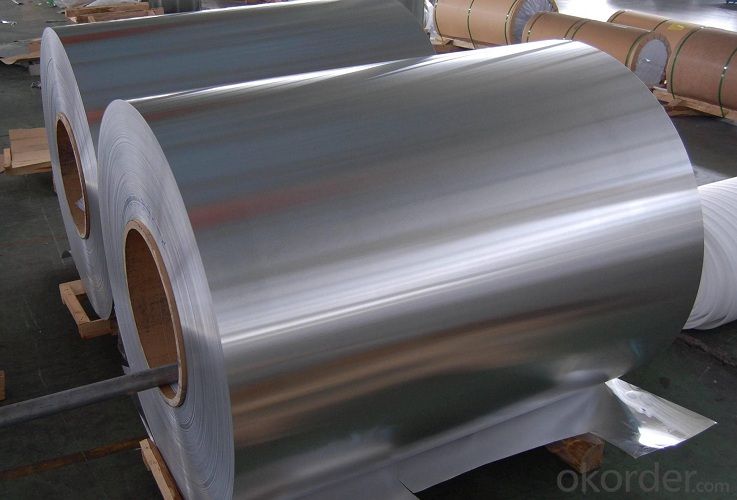

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: Can aluminum coils be used in the production of aluminum composite doors?

- Yes, aluminum coils can be used in the production of aluminum composite doors. Aluminum coils are often used as the primary material for manufacturing aluminum composite doors due to their durability, lightweight nature, and corrosion resistance. These coils are typically processed and shaped into different components of the door, such as panels, frames, and profiles, to create a strong and aesthetically appealing final product.

- Q: How to pull the aluminum coil purchased into aluminum sheet?

- You can use decoiler machine, but after decoiling, the embossment of embossed aluminum sheet will become very shallow.

- Q: What is a better deal?Aluminum Cookware ( Paula Deen)orHard Anodized ( Rachael Ray )

- NEITHER ONE ---------THE BEST COOKWARE IS MADE WITH 14 / 10 STAINLESS STEEL AND WHATEVER BRAND YOU BUY ------MAKE SURE THEY HAVE A ALUMINUM SLUG IN THE BASE FOR EVEN HEATING . THE BRAND I BOUGHT WAS COMMAND PERFORMANCE SOLD ON H.S.N. -----THEY HAVE TEMPERED GLASS LIDS AND 24 KT GOLD PLATED HANDLES ----WORK GREAT AND LOOK GREAT ON DISPLAY .

- Q: What is an aluminum coil?

- An aluminum coil is a long, flat, and thin piece of aluminum that is typically wound into a spiral shape. It is commonly used in various industries, such as construction, automotive, and electrical, due to its excellent corrosion resistance, lightweight nature, and high conductivity. Aluminum coils are often used for manufacturing products like gutters, roofing materials, heat exchangers, and electrical components.

- Q: How much will be burned out if the soaked and oxidized 5182 aluminum coil is melt down and reprocessed?

- Burn out rate is generally between 1% -2.5%, but that varies among plants as their actual situations are different.

- Q: Are there any specific regulations for the transportation of aluminum coils?

- Yes, there are specific regulations for the transportation of aluminum coils. These regulations aim to ensure the safe handling and transport of aluminum coils to prevent any accidents or damage. Some of the key regulations include: 1. Packaging requirements: Aluminum coils should be properly secured and packaged in suitable containers to prevent shifting, damage, or falling during transportation. This may include the use of strapping, banding, or shrink-wrapping. 2. Weight restrictions: There are weight restrictions on the transport of aluminum coils, which vary depending on the type of transportation mode being used. These restrictions are in place to ensure the stability and safety of the vehicle during transit. 3. Loading and unloading procedures: Proper loading and unloading procedures should be followed to minimize the risk of damage to the coils and to ensure the safety of workers. This may involve the use of specialized equipment such as cranes or forklifts. 4. Hazardous materials regulations: In some cases, aluminum coils may be considered hazardous materials due to their flammability or other characteristics. If this is the case, additional regulations and requirements may apply, such as proper labeling, documentation, and handling procedures. 5. Transportation permits: Depending on the size, weight, and destination of the aluminum coils, specific permits or licenses may be required for their transportation. These permits ensure compliance with local, state, and federal regulations. It is important for companies involved in the transportation of aluminum coils to be aware of and comply with these regulations to ensure the safe and efficient transport of the coils. Failure to adhere to these regulations can result in fines, penalties, or even legal consequences.

- Q: What is the reason for the grooves that go around the circumference of a tin/aluminium can? It can't be for grip because they're covered with paper anyway and i don't think it would make much difference.

- This is the correct answer. This is a Microsoft Interview Question Source: How Would You Move Mount Fuji?: Microsoft's Cult of the Puzzle -- How the World's Smartest Companies Select the Most Creative Thinkers There was a time when cans were in rectangular shape and made of heavy steel. As can companies became more cost and environment conscious, they figured out ways to switch to thinner aluminum cans. The thin aluminum is less strong. Like eggshells, today's cans are just about as thin as they can be and still reliably enclose their contents. This demands architectural tricks that weren't necessary with the steel cans. The thickest and strongest part of the can is the top, attached separately with a crimp. The top has to stand the stress of someone ripping open the flip top. Because the top is thicker metal, the manufacturers found it desirable to minimize its diameter. So they shrunk the top a little. This meant adding a bevel at the top to connect it to the rest of the can. (They couldn't shrink the diameter of the whole can, or it would hold less beer.) Once you shrink the top, you also have to shrink the bottom, for the cans are supposed to stack. Both top and bottom are tapered. There are other reasons why thebottom is tapered. The bottom and middle are pressed from a single piece of thin aluminum, eliminating the extra step of attaching a separate bottom to the can. This is easiest to do when there is a bevel rather than a sharp right angle. The bevel also makes the can a little more dent-proof at the ends. You could get a similar strengthening effect with a convex bottom, but then the cans wouldn't stack.

- Q: helicopters rotorblades are made of honeycombed aluminum to give them strength, so isn't it a good idea for automakers to use the same technology to strengthen the frames of autos to make them lesslikely to cave in during a side impact auto accident?

- I'm not sure you are using Honeycombed aluminum in the right context. Honeycombed aluminum is generally a method of taking a solid sheet of aluminum and carving out areas so that rails of honeycombs are left on one side and the other still looks solid. However this is not done for strength, it is done for the weight savings. Like you said, helicopter rotors are milled so that the aluminum is honeycombed, but this is to shave off a few hundred pounds of metal, which means more passengers or lifting capability. Now honeycombed aluminum has about 70% of the strength of solid aluminum, given its impacted at the right angle. In this respect it could be used on cars to give comparable strength but give far better fuel economy just because your not lugging around all that weight.

- Q: This question asks for methods to clean an aluminum coil, which involves understanding the appropriate cleaning materials and techniques to avoid damaging the aluminum.

- <p>To clean an aluminum coil, start by using a soft cloth or sponge dampened with warm water and mild dish soap. Gently wipe the coil to remove dirt and grime. Avoid abrasive materials or harsh chemicals that could scratch the surface. After cleaning, rinse the coil thoroughly with clean water to remove any soap residue. Dry the coil completely to prevent water spots or corrosion. For stubborn stains, consider using a specialized aluminum cleaner, but always follow the manufacturer's instructions and test on a small area first.</p>

- Q: I need to make aluminum powder. What machine should I use and what aluminum object should I use?

- I'm not sure I want to answer as its dangerous and can be used to make explosives.

Send your message to us

3003 H14 Aluminum Coil for Building Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords