LZHOT-DIP GALVANIZED STEEL

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

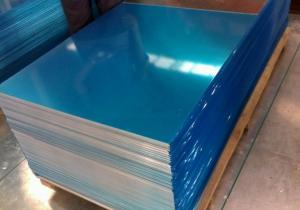

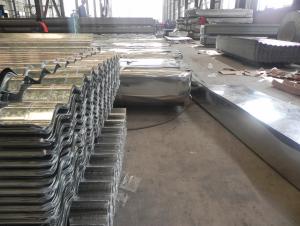

HOT-DIP GALVANIZED STEEL 72104910

THICKNESS:0.18mm-1.5mm

WIDTH:900mm-1250mm

COATING MASS:Z30-Z275

SPANGLE:Regular Spangle,Minimized Spangle,Zero Spangle

SURFACE TREATMENT:N0on or Chromated,Non or Oiled,Non or Anti Finger Print

COIL INNER DIAMETER:508mm/610mm

COIL WEIGHT:3mt-7mt

In continuous units in cold rolled steel strip, galvanized steel (electro galvanized and hot dip galvanized) as substrate, after surface pretreatment (degreasing and science processing), using the method of roll coating, coated with a layer or multi-layer liquid coating of plate, after baking and cooling income is the coating steel plate. Because the coating can have a variety of colors, on the habits of the coated steel sheet is called color coating steel plate. Because the coating is carried out before the sheet metal forming, in foreign countries which is called pre coating plate.

Color coated steel sheet is an organic coating coating on the steel surface, it has the advantages of beautiful appearance, bright color, high strength, good corrosion resistance, easy processing molding, but also allows the user to reduce costs, reduce pollution.

From the United States in 1935 to establish the first continuously coated steel line to begin, color coated steel plate has been widely applied, the current color coated plate varieties, about more than 600 kinds, the advantages of color coated sheet and organic polymer and steel plate of the two, which has good colorability, organic polymer molding, corrosion resistance and decorative, and steel plate with high strength and easy processing, can easily be punching cutting, bending, deep drawing processing. Made this makes organic coated steel sheet products have excellent practical, decorative, workability, durability.

- Q: How do you cut a steel sheet?

- To cut a steel sheet, you will need to use the appropriate tools and techniques. Here are a few common methods: 1. Power tools: The most common power tool used for cutting steel sheets is an angle grinder equipped with a cutting disc. Make sure to wear safety goggles and gloves while operating the grinder. Mark the cutting line on the sheet using a marker or chalk, then slowly and steadily guide the grinder along the marked line to cut through the steel. 2. Shears: If you are cutting a thin steel sheet, you can use manual or electric shears. These tools have a scissor-like cutting mechanism specifically designed for cutting metal. Place the steel sheet between the blades of the shears, aligning the cutting line with the blades, and apply steady pressure to cut through the sheet. 3. Plasma cutting: This method is best suited for thicker steel sheets. Plasma cutting involves using a high-velocity jet of ionized gas (plasma) to melt and sever the metal. It requires specialized equipment, such as a plasma cutter, which uses an electric arc to create the plasma jet. 4. Waterjet cutting: Another effective method for cutting steel sheets is waterjet cutting. It uses a high-pressure jet of water mixed with an abrasive substance (such as garnet) to cut through the metal. This technique is ideal for complex shapes and precise cuts, but it requires specialized machinery. Before attempting to cut a steel sheet, always prioritize safety. Wear appropriate protective gear, such as safety glasses, gloves, and a face shield if necessary. Additionally, ensure that you are working in a well-ventilated area to avoid inhaling any fumes or particles generated during the cutting process.

- Q: What is the difference between a steel strip and a coil? The steel strip is flat steel, and the steel coil is made of steel. Is that correct?

- A steel strip is also a coil, usually a narrow strip, also known as a steel strip.

- Q: Are the steel sheets available in different grades?

- Yes, steel sheets are available in different grades.

- Q: What is the difference between a satin and mirror finish steel sheet?

- The main difference between a satin and mirror finish steel sheet lies in their appearance. A satin finish has a smooth, brushed texture with a muted sheen, while a mirror finish has a highly reflective, glossy surface that resembles a mirror. The satin finish is achieved through a process of sanding or brushing the steel, creating fine lines or grain, whereas a mirror finish requires additional polishing and buffing to achieve its reflective quality.

- Q: Can steel sheets be used for elevator manufacturing?

- Yes, steel sheets can be used for elevator manufacturing. Steel is a commonly used material in elevator construction due to its strength, durability, and resistance to fire and corrosion. Steel sheets are often used to fabricate the walls, floors, and doors of elevator cabins. Additionally, steel is also utilized for the structural framework and support components of the elevator system. The use of steel sheets in elevator manufacturing provides stability, safety, and longevity to the elevator, making it a reliable choice for vertical transportation.

- Q: The method of making spring steel for automobile?

- Steel plate like spring can not be used as a knife. No material, easy to the teeth. If the shape of the tool is not required, the spring coil of the shock absorber can be used.

- Q: Are steel sheets resistant to impact and vibration?

- Yes, steel sheets are generally resistant to impact and vibration due to their strong and sturdy nature.

- Q: What are the different types of coatings available for steel sheets?

- There are several types of coatings available for steel sheets, including galvanized coatings, zinc coatings, tin coatings, aluminum coatings, and polymer coatings. Each type of coating offers unique properties and benefits, such as corrosion resistance, improved durability, enhanced aesthetics, and increased protection against environmental factors. The choice of coating depends on the specific application and desired characteristics of the steel sheets.

- Q: Can steel sheets be used for chimneys and flue systems?

- No, steel sheets are not suitable for use in chimneys and flue systems as they cannot withstand high temperatures and are prone to corrosion.

- Q: Are steel sheets suitable for oil rig platforms?

- Oil rig platforms benefit greatly from the use of steel sheets. The reason for this lies in the exceptional strength and durability of steel, which makes it a popular choice in their construction. Given the harsh environmental conditions that oil rig platforms face, such as extreme temperatures, high winds, and corrosive saltwater, steel has proven itself capable of withstanding these challenges effectively. Steel sheets offer a solid and dependable base for oil rig platforms. They ensure that the platforms can bear the weight of the rig, equipment, and personnel without compromising stability or safety. The high strength of steel allows for the construction of large and intricate structures without sacrificing stability. Moreover, steel exhibits remarkable resistance to corrosion, making it an ideal material for offshore applications. Oil rig platforms are constantly exposed to saltwater, which can cause corrosion and weaken other materials. However, steel sheets can be treated with protective coatings to enhance their resistance to corrosion and extend their lifespan. In addition to its strength and corrosion resistance, steel is a versatile material that lends itself to easy shaping and fabrication. This versatility allows for efficient and cost-effective construction processes, reducing the time and resources required for installation and maintenance. In conclusion, steel sheets are a suitable choice for oil rig platforms due to their strength, durability, corrosion resistance, and versatility. They provide a reliable and robust foundation for offshore drilling operations, ensuring the safety and longevity of the platform in challenging environments.

Send your message to us

LZHOT-DIP GALVANIZED STEEL

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords