Low Temperature Pressure Vessel Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

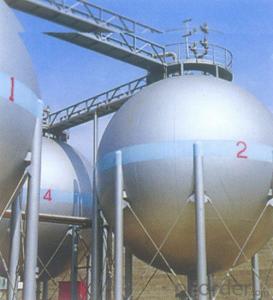

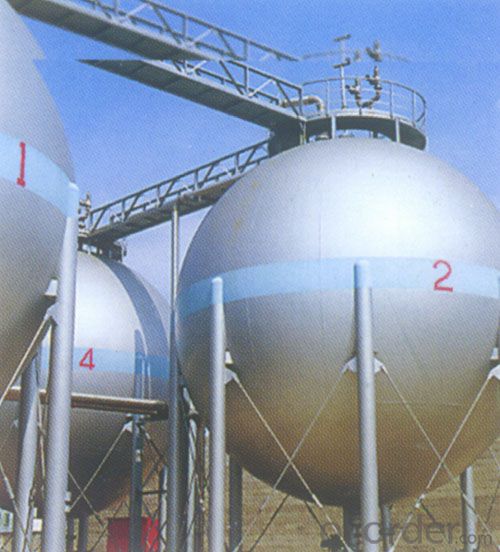

Low temperature pressure vessel (low temperature pressure vessel), is a kind of cryogenic vessel.

Summary

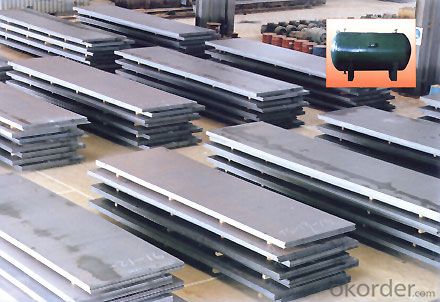

Design of temperature for pressure vessel -20 DEG C; the container is of low temperature pressure vessel for storage and transportation of liquefiedethylene and liquefied natural gas, liquid nitrogen and liquid hydrogen etc..The general pressure vessel commonly used ferritic steels in the temperaturedown to a temperature, the toughness of the steel will decrease sharply, and is very brittle, this temperature is usually referred to as the ductile brittle transition temperature. The use of pressure vessel in below the transition temperature conditions, due to defects, residual stress, stress concentrationand other factors caused by the high local stress such as the existence of a container, the container may be in no obvious plastic deformation under the condition of brittle rupture and disastrous accident. For low temperature pressure vessel must first select suitable materials, these materials should have good toughness at service temperature. The grain size of low alloy steelsavailable to -45 DEG C, 2.5% nickel steel available to -60 DEG C, 3.5% nickel steel available to -104 DEG C, available at -196 deg.c for 9% nickel steel.Below -196 DEG C when the selection of austenitic stainless steel andaluminum alloy etc.. In order to avoid local high stress in low temperaturepressure vessel, in the design of container should avoid excessiveconcentration of stress and additional stress; be strict inspection inmanufacturing the container, in order to prevent dangerous defects exist in the container. For because of the welding residual stress caused by excessive,should eliminate welding residual stress treatment after welding.

Performance characteristics

Cryogenic vessel performance and features of industrial [1] with liquid nitrogenat extremely low temperatures by nitrogen pressure variable is a colorless liquid, low temperature container at liquid nitrogen temperature is very low, and then use the cylinder holding, then put the cylinder in normal temperature, due to the environment temperature, temperature of liquid nitrogen is placed inside the bottle rises, also into the room temperature, then the liquid nitrogen in the bottle pressure will become higher.

But in the actual case, either the cylinder heat preservation effect is very good,or pressure safety valves, cylinders placed either opening time is very short.The cylinder temperature could not reach the normal temperature.

The industrial use of the liquid nitrogen at extremely low temperatures by nitrogen pressure variable is a colorless liquid, then the liquid nitrogentemperature is very low, and then use the cylinder holding, then put the cylinder in normal temperature, low temperature storage tank due to environmental temperature, then:

The bottle containing liquid nitrogen transformation could take place, i.e.vaporized, by liquid nitrogen into gaseous nitrogen, the cylinder pressure rise,this time the inside temperature or liquid nitrogen and nitrogen coexisttemperature is generally -196 degrees, absorb heat temperatures continue to rise, the pressure continues to rise, pressure safety valve will work, relief. If nopressure relief, only temperature, pressure of liquid nitrogen in the cylinder will be very high, resulting in high pressure vessel explosion.

Liquid nitrogen tank insulation effect is very good, the liquid nitrogen can bestored for 1 months does not vaporize finish inside.

- Q: How are steel sheets tested for quality and performance?

- Steel sheets are tested for quality and performance through a variety of methods, including visual inspection, dimensional checks, mechanical testing, and chemical analysis. Visual inspection ensures that the surface is free from defects such as cracks, scratches, or unevenness. Dimensional checks verify that the sheet meets the required thickness, width, and length specifications. Mechanical testing involves subjecting the sheet to various stress tests to determine its strength, ductility, and resistance to deformation. Chemical analysis is performed to assess the composition of the steel, ensuring it meets the required standards and specifications. These tests collectively help ensure that the steel sheets meet the necessary quality and performance standards for their intended applications.

- Q: How do steel sheets compare to glass sheets?

- Different applications require distinct characteristics in steel sheets and glass sheets. To begin with, steel sheets are renowned for their strength and durability, enabling them to bear heavy loads and resist impact and damage effectively. Consequently, they are well-suited for construction purposes, including building manufacturing, bridge construction, and machinery development. Furthermore, steel sheets provide excellent fire protection and can withstand extreme weather conditions. On the other hand, glass sheets are highly valued for their transparency and aesthetic appeal. By allowing natural light to pass through, they create a bright and open atmosphere. Consequently, glass sheets are commonly used in windows, doors, and architectural structures to enhance visibility and the visual appeal of a space. Additionally, glass sheets possess excellent thermal insulation properties, which aid in reducing energy consumption in buildings. When it comes to maintenance, steel sheets require minimal upkeep due to their corrosion resistance and infrequent need for cleaning. However, they may require painting or protective coatings to prevent rusting. Conversely, glass sheets may need regular cleaning to maintain their transparency and appearance. Moreover, they are more prone to scratching and breakage compared to steel sheets. Lastly, cost must be considered. Generally, steel sheets have a lower initial cost compared to glass sheets. However, the overall cost may vary depending on factors such as size, thickness, and quality. Additionally, the installation and maintenance costs should also be taken into account. In conclusion, steel sheets and glass sheets possess unique characteristics and properties. The choice between the two depends on specific project requirements, including strength, transparency, aesthetics, maintenance, and cost considerations.

- Q: What are the different types of steel coatings for sheets?

- Some of the different types of steel coatings for sheets include galvanized steel, zinc-coated steel, tin-plated steel, and stainless steel.

- Q: What is the process of applying anti-slip patterns to steel sheets?

- The process of applying anti-slip patterns to steel sheets typically involves embossing or etching the surface of the sheet with raised patterns or textures. This can be done using specialized machinery or through chemical treatments. The patterns are designed to increase friction and traction, making the steel sheet less slippery and safer to walk on.

- Q: Can steel sheets be used for roofing purposes?

- Yes, steel sheets can be used for roofing purposes. Steel is a durable and long-lasting material that is resistant to corrosion, making it an excellent choice for roofing. Steel sheets provide strength and stability to the roof, protecting the building from various weather conditions. Additionally, steel roofs are low maintenance and can be energy-efficient if properly insulated.

- Q: Are steel sheets suitable for harsh weather conditions?

- Steel sheets are highly suitable for harsh weather conditions due to their durability and strength. Steel is renowned for its ability to withstand extreme weather conditions, including high winds, heavy rain, snow, and hail. Moreover, steel sheets are designed to resist corrosion, rust, and degradation caused by prolonged exposure to severe weather, ensuring their longevity and dependability in any climate. Furthermore, steel sheets can be coated with protective finishes, such as galvanized or painted coatings, which further enhance their resistance to weathering. This aspect has made steel sheets a popular choice for various applications in areas prone to harsh weather, such as roofing, siding, and outdoor structures. They provide exceptional protection and structural integrity even in the most challenging weather conditions.

- Q: What is the process of applying protective coatings to steel sheets?

- The process of applying protective coatings to steel sheets involves several steps. First, the steel sheets are cleaned to remove any dirt, grease, or other contaminants. This can be done through various methods such as chemical cleaning, power washing, or sandblasting. After cleaning, the sheets are dried thoroughly to ensure a clean and dry surface. Next, a primer or undercoat is applied to the steel sheets. The primer helps in promoting adhesion and corrosion resistance. It is essential to choose a primer that is compatible with the type of coating being applied. Once the primer is dry, the protective coating is applied. This can be done through methods like spray painting, dip coating, or electrostatic coating. The type of coating used depends on the specific requirements and properties desired for the steel sheets. After application, the coated steel sheets are cured or dried, typically through air drying or baking in an oven. This ensures that the coating adheres properly and forms a protective layer on the steel surface. Overall, the process of applying protective coatings to steel sheets involves cleaning, priming, coating, and curing steps to enhance the durability, corrosion resistance, and aesthetic appearance of the steel sheets.

- Q: How are steel sheets protected during transportation by sea?

- Steel sheets are protected during transportation by sea through various measures such as applying corrosion-resistant coatings, packing them in moisture-proof and weather-resistant materials, securing them with appropriate lashing and bracing, and using specialized shipping containers or vessels equipped with proper ventilation and humidity control systems. These measures ensure that the steel sheets remain intact, free from rust, and undamaged throughout the sea voyage.

- Q: What is the process of manufacturing steel sheets?

- The process of manufacturing steel sheets involves several steps. First, iron ore is extracted from the ground and processed to remove impurities. This iron ore is then smelted in a blast furnace, along with coke and limestone, to produce molten iron. The molten iron is further refined in a basic oxygen furnace or an electric arc furnace to remove any remaining impurities and adjust the desired composition. Once the iron has been refined, it is converted into steel by adding alloying elements such as carbon, manganese, and other elements as required. The molten steel is then cast into large slabs or ingots. These slabs are reheated and passed through rolling mills to reduce their thickness and shape them into long, flat sheets. The sheets are then cooled, coated or treated as necessary, and cut into desired sizes before being packaged and shipped for various applications.

- Q: What is the cost of steel sheets compared to other materials?

- The price of steel sheets can vary depending on factors such as the type of material, size, thickness, and market conditions. Typically, steel sheets are pricier than materials like aluminum or plastic, but they are renowned for their durability and strength. Industries like construction, automotive, and manufacturing commonly utilize steel sheets due to their ability to bear heavy loads and resist corrosion. Although steel sheets may have a higher initial cost, they often have a longer lifespan and require less maintenance compared to other materials. Furthermore, the cost of steel sheets can change based on global supply and demand dynamics, as well as any tariffs or trade restrictions that affect the steel market.

Send your message to us

Low Temperature Pressure Vessel Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords