Low Smoke Halogen Free Flame Retardant Polyolefin Insulating Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyolefin:

1. competitive price

2. 30 years of experience

3. stable quality

4. customized product

Polyolefin:

1. Applications and cable specifications of Polyolefin:

Common insulation for flame retardant wires and cables.

2. Description of Polyolefin:

Thermoplastic, low-smoke, halogen-free and flame retardant POE insulating compound, based on POE resin, is produced and pelletized by special technology with adding special modifier, flame retardant, anti-oxidant and other special additives.

3. Processing of Polyolefin:

The compound can be processed with conventional extruders, and the screw with a minimum 20:1 L/D and a compression ratio of 1.2 is recommended.

The following temperature(°C) profile of extruder is recommended:

| Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

| temperature degree C | 140 | 145 | 150 | 150 | 145 | 145 |

Note:Compound should be dried at 70-80°Cbefore use, which has storage time exceeding two months.

4. Storage and transport of Polyolefin:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag

Avoiding in direct sunlight and weathering

Storage place should be in clean, cool, dry and ventilated conditions

5. Properties of Polyolefin:

| Item | Unit | DW9003 | DW9003A | DW9003B | DW9003C | ||||

| Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | ||

| Density | g/cm3 | -- | 1.46 | -- | 1.45 | -- | 1.43 | -- | 1.49 |

| Hardness | Shore A | -- | 95 | -- | 94 | -- | 93 | -- | 97 |

| Tensile Strength | ≥MPa | 9 | 12.5 | 9 | 12 | 9 | 13 | 9 | 12.5 |

| Elongation at Break | ≥ % | 125 | 210 | 125 | 160 | 125 | 200 | 125 | 180 |

| Thermal Aging | degree C×h | 110×240 | 110×240 | 110×240 | 110×240 | ||||

| TS/EB Retention | ≥ % | 75/75 | 110/83 | 75/75 | 108/87 | 75/75 | 112/89 | 75/75 | 112/85 |

| Hot Deformation 80 degree C 4(6)h | ≤ % | 50 | 24 | 50 | 25 | 50 | 21 | 50 | 19 |

| Impact Brittleness Temperature | ≤ degree C | -20 | Pass | -20 | Pass | -20 | Pass | -20 | Pass |

| Volume Resistivity, at 20 degree C | ≥Ω*m | 1.0×1012 | 2.1×1012 | 1.0×1012 | 2.0×1012 | 3.0×1012 | 6.0×1012 | 1.0×1012 | 3.8×1012 |

| Oxygen Index | ≥ | 30 | 35 | 28 | 29 | 28 | 30 | 35 | 37 |

| Smoke Density Flaming | ≤ | 100 | 60 | 100 | 68 | 100 | 70 | 100 | 60 |

| Non flaming | ≤ | 200 | 140 | 200 | 145 | 200 | 135 | 200 | 130 |

| Acidity of gases evolved (pH) | ≥ | 4.3 | 5.6 | 4.3 | 5 | 4.3 | 5.2 | 4.3 | 6.1 |

| Conductivity of gases evolved | ≤μs/mm | 10 | 1 | 10 | 1 | 10 | 0.9 | 10 | 0.9 |

| Content of halogen acids | ≤ mg/g | 5 | 1 | 5 | 1.2 | 5 | 1 | 5 | 1 |

| Toxicity Index | ≤ | 2.5 | 1.1 | 2.5 | 1.2 | 2.5 | 1 | 2.5 | 1 |

| Thermal Impact Test | |||||||||

| Condition 150 degree C * 1h | No cracking | Pass | No cracking | Pass | No cracking | Pass | No cracking | Pass | |

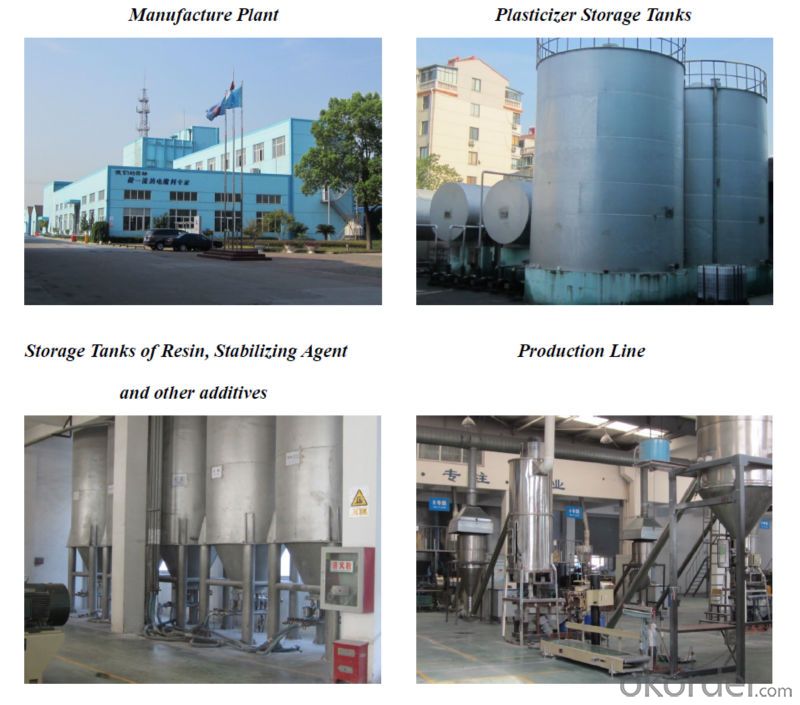

6. Company

- Q: What material is best for plastic gears?

- At present, the demand for plastic gear with high wear resistance and noiseless gear is very strong. POLYMSJ noiseless nylon composite occupies a leading position in this field. If it doesn't solve the problem, you can try it out.

- Q: I made of plastic raw materials accessories containing benzene, how to remove the teacher, please enlighten!

- Benzene is generally not used as a plastic processing aid, even if mixed with a little, the plastic molding process in the high temperature also make it has long been volatile.

- Q: What is the plastic basin made of?

- The raw material is PP and PE, the raw material price is more than 10000, and some can be recycled at around 5000.

- Q: What material is good for plastic bellows?

- In the cases to recommend the use of PE (polyethylene) bellowsNo oxidizing acids, no environmental oils, vegetable oils, mineral oils, no organic solvents such as aliphatic hydrocarbons, aromatic hydrocarbons, ketones, esters, etc..Mainly used in the temperature range of -40 to 80 degrees Celsius environment; used in automobiles, motorcycles and other motor vehicle wire harness sheath; also used for household appliances, precision machine tools and other equipment wiring wire sheath.

- Q: How do plastic raw materials trade? How big is the market?

- Traditional trading model is to realize the circulation of plastic raw materials with contacts, telephones and fixed customers. The Internet trading mode of transaction is transferred from the line to line, from order flow to terminal distribution capabilities are strong, with IT technology and services to provide information, plastic raw materials trading, a full range of logistics finance.

- Q: Characteristics and uses of CA plastics

- Because of its characteristics and quality of different varieties are different, generally use as general plastics, in addition to avoid the use of related in food packaging, medical devices and health fields, the other is used. For example, car interior and exterior shell, household appliances and other daily necessities, mainly low price.

- Q: Does anyone know what kind of plastic material PP-M40 is?

- Compared with the ordinary PP, the filling PP has the advantages of less shrinkage, higher rigidity and good heat resistance, and is suitable for being used as an electric cooker, an inner ring, an automobile, a motorcycle fitting, etc..

- Q: What plastic material is resistant to high temperature?

- High temperature resistant plastic material:PPS: (PPS)Polyphenylene sulfide (abbreviated as PPS) is a new type of high performance thermoplastic resin. It has the advantages of high mechanical strength, high temperature resistance, chemical resistance, flame resistance, good thermal stability and good electrical performance. It is widely used in the fields of electronics, automobile, machinery and chemical engineering

- Q: PVC what is the difference between raw and recycled raw materials?

- Products using recycled materials are brittle, easy to break or burst, very durable.

- Q: What are the raw materials for producing plastic films?

- Film type: PVA coated high barrier film, biaxially oriented polypropylene film (BOPP) and low density polyethylene film (LDPE), polyester film (PET), nylon film (PA), polypropylene (CPP) film, etc..

Send your message to us

Low Smoke Halogen Free Flame Retardant Polyolefin Insulating Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords