Irradiation Cross-linkable Low Smoke Zero Haogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

lszh compound:

1. Applications and cable specifications:

Type | Product | Application and Cable Specification |

FDW1186 | 110℃ Irradiation cross-linked, low-smoke, halogen-free and flame retardant POE jacket compound | 105℃ jacket for cross-linked flame retardant wires and cables, meeting the standard of HF-110-R, E-110-R of AS 3808. |

FDW1180 | 110℃ Irradiation cross-linked, low-smoke, halogen-free and flame retardant POE insulating compound | 110℃ Insulation for cross-linked flame retardant wires and cables, meeting the standard of R-E-110, X-HF-110, R-HF-110 of AS 3808. |

DW9022-C01 | 90℃ Thermoplastic Low-smoke, halogen-free and flame retardant POE jacket compound | 90℃ common jacket for flame retardant wires and cables, meeting the standard of HFS-90-TP and HFS-110-TP of AS 3808. |

2. Description:

High temperature resistant irradiation cross-linked low-smoke halogen-free and flame retardant POE compound, based on POE resin, is produced and pelletized by special technology, adding special modifier, halogen-free flame retardant, anti-oxidant, crosslinking sensitizer and other special additives.

3. Processing:

The compound can be processed with conventional extruders, and the screw with a minimum 20:1 L/D and a compression ratio of 1:1.2 is recommended.

The following temperature(°C) profile of extruder is recommended:

Type | Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

FDW1186 | temperature °C | 90 | 125 | 140 | 145 | 145 | 145 |

FDW1180 | temperature °C | 90 | 125 | 140 | 145 | 145 | 145 |

DW9022-C01 | temperature °C | 125 | 145 | 150 | 160 | 160 | 160 |

Note:Compound should be dried at 60-70°C before use, which has been stored more than two months.

4. Irradiated dosage

The normal irradiated dosage(recommended) of high temperature resistant, irradiation cross-linked, low-smoke, halogen-free and flame retardant POE compound is 15 to 18 megarad.

5. Storage and transport:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

6. Properties:

| Item | Unit | FDW1186 | FDW1180 | DW9022-C01 | |||

| Standard | Typical | Standard | Typical | Standard | Typical | ||

| Density | g/cm3 | — | 1.48 | — | 1.23 | — | 1.34 |

| Hardness | Shore A | — | 86 | — | 81 | 94 | 92 |

| Tensile Strength | ≥ MPa | 6 | 12 | 5 | 9.5 | 6 | 11 |

| Elongation at Break | ≥ % | 125 | 160 | 125 | 400 | 125 | 360 |

| Thermal Aging | |||||||

| Aging Temperature | °C | 130±2 | 130±2 | 150±3 | 150±3 | 110±2 | 110±2 |

| Aging Time | h | 480 | 480 | 168 | 168 | 480 | 480 |

| Tensile Strength | ≥ % | 6 | 10 | Retention 70 | 85 | 6 | 8.7 |

| Elongation at Break | ≥ % | 100 | 150 | Retention 70 | 82 | 100 | 280 |

| Thermal Prolongation 20N/cm2 | °C×min | 200×15 | 200×15 | — | — | ||

| Elongation Under Load | ≤ % | 175 | 25 | 175 | 50 | — | — |

| Permanent Deformation | ≤ % | 15 | 0 | 15 | 0 | — | — |

| Volume Resistivity, at 20°C | ≥Ω*m | 1.0×1011 | 2.0×1012 | 1.5×1012 | 3.0×1012 | 1.0×1011 | 2.0×1012 |

| Dielectric Strength | ≥KV/mm | 18 | 23 | 20 | 25 | — | — |

| Oxygen Index | ≥ % | 33 | 34 | — | 28 | 30 | 34 |

| Impact Brittleness Temperature | °C | — | — | — | — | — | — |

| Smoke Density Flaming | ≤ | 100 | 61 | — | — | — | — |

| Non flaming | ≤ | 200 | 142 | — | — | — | — |

| Acidity of gases evolved (pH) | ≥ | 4.3 | 5.8 | 3.5 | 4.2 | 3.5 | 4 |

| Conductivity of gases evolved | ≤μs/cm | 2.5 | 0.9 | 100 | 6 | 100 | 28 |

| Oil Resistant Test | |||||||

| Test Temp. Time | °C×h | 120×18 | 120×18 | — | — | — | — |

| Retention on Tensile Strength | ≥ % | 60 | 65 | — | — | — | — |

| Retention on Elongation at Break | ≥ % | 60 | 72 | — | — | — | — |

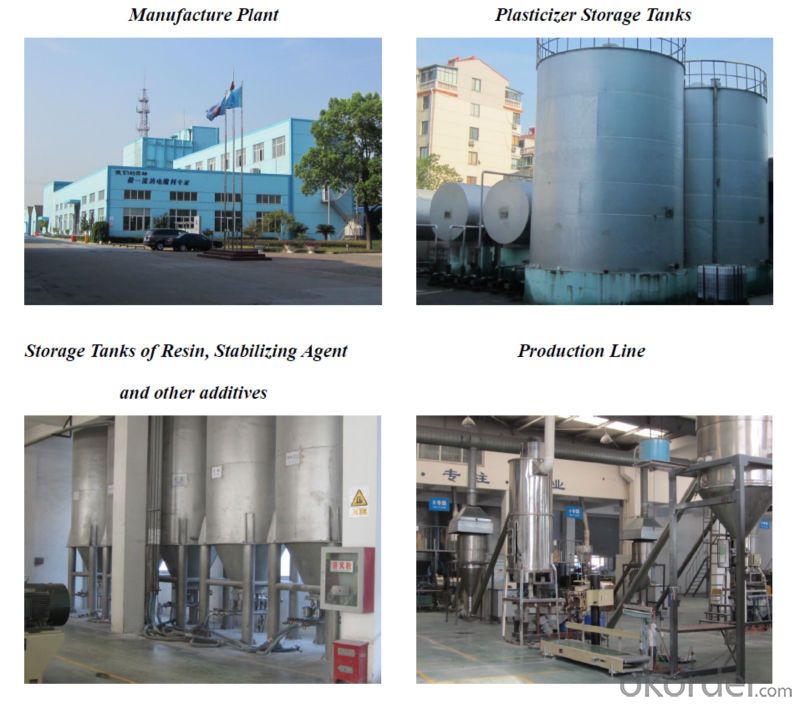

7. Company

- Q: Pollution in the production of plastic raw materials from petroleum production

- Petroleum - intermediate - polymerization monomer - resin - plastic particles - plastic products, the process of the above, each will have pollutants!

- Q: I made of plastic raw materials accessories containing benzene, how to remove the teacher, please enlighten!

- The use of benzene: fats, resins and iodine and other solvents. Determination of mineral refractive index. Organic synthesis. Optically pure solvent. High pressure liquid chromatography is used as solvent, synthetic dyes, pharmaceuticals, pesticides, petroleum and chemical products, photographic materials, varnishes, nitrocellulose lacquer thinners, paint remover, lubricating oil, grease, wax, Sai Luluo, resin, artificial leather and other solvents. It must be the raw material you bought that contains some other additives. Benzene is not removed

- Q: What material is good for plastic bellows?

- In the next case, it is recommended to use PP (polypropylene) bellowsNo strong acid and high concentration of oxidant in the environment; in more than 80 degrees Celsius in the environment of soluble in benzene, toluene and other aromatic hydrocarbons and chlorinated hydrocarbons in oil absorption; for most stable, small amount of mineral oil and vegetable oil.Mainly used in the temperature range of -20 to 120 degrees Celsius environment; used in automobiles, motorcycles and other motor vehicle wire harness sheath; also used for household appliances, precision machine tools and other equipment wiring wire sheath.

- Q: Plastic raw materials, why LDPE and LLDPE?

- LDPE is a low density polyethylene with a large number of branched structures. The molecular structure is lack of regularity, so the crystallinity of LDPE is small, 65%~75%, and the density is low, 0.91~0.93 grams / cubic centimeter. LLDPE is a linear low density polyethylene. Its molecular structure is linear, branched less, branched short, and its density is similar to that of LDPE. Its physical and mechanical properties are better than those of LDPE.

- Q: How to make plastic raw materials?

- oil refiningPetroleum crackingCracking is the process of breaking down hydrocarbons with relatively large molecular weight and high boiling point under certain conditions, which are relatively small molecular weight and low boiling point hydrocarbons.Cracking under catalysis, also known as catalytic cracking.

- Q: What kinds of plastic properties can be divided into thermal properties?

- Classification of plastics (100 million nylon)There are many kinds of plastics. There are many kinds of classification methods. They are usually divided into two categories: thermoplastic and thermosetting plastics according to the change of their properties after heating.

- Q: What kind of raw material is plastic hollow board made of?

- PP plastic hollow board made of hollow board packaging products are non-toxic, the processing temperature (DEG) 180~240 when making. So boiling water doesn't break it down. Therefore, there is no need to worry whether there is any toxicity in the empty plate.

- Q: PVC what is the difference between raw and recycled raw materials?

- Products using recycled materials are brittle, easy to break or burst, very durable.

- Q: What are the raw materials needed for making plastic bags?

- The bags made of two materials each have their own characteristics, and are chosen according to the purpose and performance of the products. Polyethylene is petrochemical products, prices vary according to crude oil and market conditions every day, at present LDPE (high pressure polyethylene) offer at 13500 yuan. HDPE (low pressure polyethylene) at 11000 yuan up and down.

- Q: What do you mean by grade 1, class two or class three in plastic?

- Two material is that the raw material has been used once, but high pressure granulation except high-pressure granulation using imported large majority, if import large industrial film has not been exposed to the weather, so the quality is very good, the processed particles with good transparency, then it should be judged according to the brightness and surface whether the rough particles.

Send your message to us

Irradiation Cross-linkable Low Smoke Zero Haogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches