Temporary Pool Fence Factory Direct Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Pieces watt

- Supply Capability:

- 50000 Pieces per Week watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

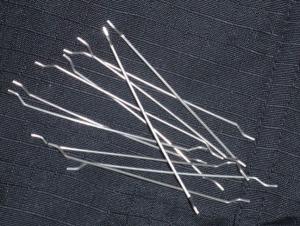

temporary pool fence

welds are fairly strong

high quality low carbon steel wire, Q235

Made from raw material

iso9001/2000

temporary pool fence

This is a kind of mobiled,repetitious using fencing product.It is mainly used in various building site or mine site for security protecting,exclosure and so on.

Packing:

1>fence panel;:plastic flim+wood/metal pallet

2>fence post:every post pack with a plastic bag(the cap is covered well on the post)+pallet

3>accessory:small plastic bag+carton box

Materials:

Mild steel wire ,Superior quality low carbon steel wire, pre-crimped.

Features:

Our temporary fencing systems can quickly and easily be installed, without the need to disturb the surface area by digging holes or laying foundations.

Application:

1. Temporary fencing to secure construction sites and private property.

2. Temporary fencing of residential housing sites.

3. Temporary fencing and crowd control barriers for major public events, sports,ect.

4. Temporary safety fencing for swimming pools.And many other uses

Description:

Using high quality of Iron Rod as raw material. Usually the surface treatment is Galvanized after welding.The fence obtain very strong powers to resist the concussion. Because there are some bends on the fence.

- Q: How many types of plastics are there?

- PVC Name: PVC, mainly used for sealing, inserted conditions. It is adapted to extrusion molding, and PVC material is the material does not burn plastic parts, processing temperature stability, especially the stability of the color is not good.

- Q: What is the difference between PA66 and PA6 plastic raw materials? Differences in price, color, performance, etc

- PA6 also known as nylon 6 is translucent or opaque white particles, thermoplastic, light weight, good toughness, chemical resistance and good durability and other characteristics, generally used for auto parts, machinery parts, electronic products, engineering accessories and other products.

- Q: How many types of plastic materials are there?

- There are many kinds of plastics. So far, there are about more than 300 kinds of plastic produced in the world. Many classification methods of plastic, there are two kinds of commonly used: 1, according to the nature of the heated plastic divided into thermoplastic and thermoset plastic molecular structure are linear structure, softening or melting when heated, plastic into certain shape, after cooling and harden. After heating to a certain extent, it softens again and hardens again after cooling. This process can be repeated many times. Such as PVC, polyethylene, polystyrene and so on. Thermoplastic molding process is relatively simple, can be continuous production, and has a high mechanical strength, so the development of very fast. The molecular structure of thermosetting plastics is the body structure, softening also occurs in heated, can plastic into a certain shape, but is heated to a certain extent or amount of curing agent, hardened stereotypes, re heating will not soften and change the shape of the. Thermosetting plastic processing, molding, the heat is no longer softening, and therefore can not be recycled, such as phenolic plastics, amino plastics, epoxy resin, etc. belong to this kind of plastic. Thermosetting plastic forming process is more complex, so continuous production has some difficulties, but its good heat resistance, not easy to deformation, and the price is relatively low.

- Q: Is the tableware made of PP raw material the best of those plastic tableware?

- Polypropylene (PP) is made from propylene. The transparency is also better than polyethylene. It is harder than polyethylene. Most of the boxes packed in the hotel are made of it. The plastic boxes can be heated in a microwave oven.

- Q: What are the raw materials of plastics made of?

- Some plastics are pure resins, such as polyethylene, polystyrene and so on. They are called single component plastics. Some plastics, in addition to synthetic resins, also contain other auxiliary materials, such as plasticizers, stabilizers, colorants, various fillers, etc., known as "multi component plastic.".

- Q: What plastic material is used for plastic hose?

- PVC: the main ingredients of PVC, bright color, corrosion resistant, durable, due to an increase in the manufacturing process of plasticizer, anti aging agent and other toxic and auxiliary materials to enhance its heat resistance, toughness, ductility, so their products generally do not store food and drug. If there is special physical property requirements, you can also increase the amount of modifier. It must not add a plasticizer has good tensile and compressive strength, but its flexibility is better than other plastic pipe, excellent corrosion resistance, the cheapest price in all kinds of plastic pipe, but low temperature brittle adhesive, rubber ring socket flange connection, threaded connection for residential living, industrial and mining industry and agriculture for drainage, irrigation, gas supply, exhaust pipe, wire pipe, rain water pipe, industrial anti-corrosion pipe etc.. The heat resistant property is outstanding, the thermal deformation temperature is 100 DEG C, the chemical resistance is excellent, and the connecting flange screw thread is connected with the hot water pipe

- Q: What are the raw materials for environmental friendly portable plastic bags?

- The more advanced shopping bags made of PBAT and PLA composites are expensive, but biodegradable plastic.

- Q: What are the raw materials needed for making plastic bags?

- The bags made of two materials each have their own characteristics, and are chosen according to the purpose and performance of the products. Polyethylene is petrochemical products, prices vary according to crude oil and market conditions every day, at present LDPE (high pressure polyethylene) offer at 13500 yuan. HDPE (low pressure polyethylene) at 11000 yuan up and down.

- Q: PP plastic stool surface with those raw materials, what is the ratio?

- In general plastics, PP has the best heat resistance, and its thermal deformation temperature is 80-100 DEG C and can be boiled in boiling water.

- Q: Is plastic raw material rubber?

- Raw materials are polymers of polymers such as polypropylene. Is generally from the fossil raw materials inside the extraction after polymerization together. A series of plastic refers to the resin as the main component, such as plasticizers, fillers, lubricants, additives such as colorants as auxiliary components, can flow in the process of forming materials. To put it simply, the oil was extracted and finally made into plastic, rubber and plastic

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2005 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Oceania Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | HACCP ;ISO 9001:2000 ;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | tianjin,huanghua,ningbo |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese, French |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Temporary Pool Fence Factory Direct Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Pieces watt

- Supply Capability:

- 50000 Pieces per Week watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords