Oil Resistant Irradiation Cross-linkable Low Smoke Zero Halogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

locomotive cable compound:

(1) competitive price

(2) 30 years of experience

(3) stable quality

(4) customized product

Locomotive Cable Compound:

1. Applications and cable specifications:

Applied to the locomotive cables which voltage is less than 3KV and temperature is 125°C.And the cable is used in the no mineral oil and no fuel oil environment.

2. Description:

Irradiation cross-linkable, low smoke halogen free and flame retardant POE compound for locomotive cables, based on special high oil resistant POE resin, is produced and pelletized by special technology with adding special stabilizing agent, modifier, halogen free flame retardant, cross-linking agent, antioxidant and other special additives. It meets the locomotive cable requirements of high temperature resistant and oil resistant.

3. Processing:

Irradiated dosage:12-15 megarad

The compound can be processed with conventional extruders, and the normal PVC screw with a minimum 20:1 L/D. It is better if use low compression ratio screw.

The following temperature(°C) profile of extruder is recommended:

| Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

| temperature °C | 130 | 145 | 150 | 150 | 145 | 145 |

4. Storage and transport:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

5. Properties:

| Item | Unit | Standard Value ( after irradiation cross-linked) | ||

| JFDW04 | JFDW05 | JFDW06 | ||

| Tensile Strength | ≥Mpa | 9 | 9 | 9 |

| Elongation at Break | ≥% | 125 | 125 | 125 |

| Thermal Aging | Condition °C×h | 158×168 | 158×168 | 158×168 |

| TS/EB retention | 80 | 80 | 80 | |

| ≥ % | 60 | 60 | 60 | |

| High temperature pressure test | Temp.°C | — | 125 | 125 |

| ≤ % | — | 50 | 50 | |

| Oil resistant | Type | — | 20# machine oil | 20# machine oil |

| condition°C×h | — | 100×70 | 100×70 | |

| Variation on Tensile Strength | ≤ % | — | -50 | -50 |

| Variation on Elongation at Break | ≤ % | — | -50 | -50 |

| Oil resistant | Type | — | — | 0# diesel oil |

| condition °C×h | — | — | 70×168 | |

| Variation on Tensile Strength | ≤ % | — | — | -55 |

| Variation on Elongation at Break | ≤ % | — | — | -55 |

| Impact Brittleness Temperature | ≤ °C | -40 | -40 | -40 |

| Volume Resistivity, at 20°C | ≥Ω.m | 1.0×1012 | 1.0×1012 | 1.0×1012 |

| Oxygen Index | ≥ | 30 | 30 | 30 |

| Smoke Density Flaming | ≤ | 100 | 100 | 100 |

| Non flaming | ≤ | 200 | 200 | 200 |

| Acidity of gases evolved (pH) | ≥ | 4.3 | 4.3 | 4.3 |

| Conductivity of gases evolved | ≤μs/mm | 10 | 10 | 10 |

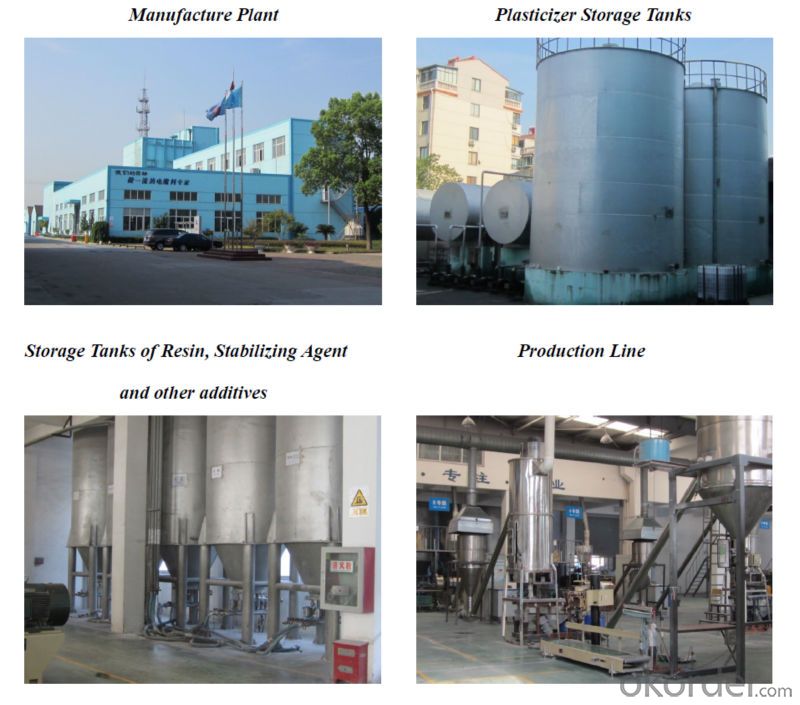

6. Company

- Q: What plastic material has great impact resistance?

- The ability of metal materials, machinery parts and components to resist impact damage is called impact strength.

- Q: What are the POE plastic raw materials?

- POE classification of plastics raw materials:Plasticizing properties: Thermoplastics and thermosetting plastics.Divided by use: General Plastics and engineering plastics.

- Q: What's the difference between recycled plastic bucket and plastic bucket made of raw material?

- Recycled materials produce more plastic impurities, so they look rougher and darker in color. If the stock is ready, the color is better. Recycled materials are very poisonous. If they are packed with food, it's best not to use them

- Q: What are the APP of plastic raw materials?

- Thermosetting plastics (phenolics, epoxy resins, unsaturated polyesters, polyurethanes, silicones, amino resins, etc.);

- Q: Characteristics of rigid polyurethane foam made of polyurethane raw material

- Polyurethane rigid foam is prepared by hard foam polyether polyol (polyurethane rigid foam combination polyether, also known as white material) and polymerized MDI (also known as black material). Mainly used in the preparation of rigid polyurethane foam, widely used in refrigerators, cold storage, spraying, solar energy, thermal pipelines, construction and other fields. According to the use of the field, divided into rigid foam polyether polyol, polyether, wood cyclopentane system hard foam polyether polyol, polyether, flame retardant polyether water. The wood is mainly used for imitation wood product polyether, polyether and water is mainly used for all water pipe foam, flame retardant polyether products for preparation of flame retardant high requirements.

- Q: What type of raw material is used in plastic bags? The brightness is good. It blows out as bright as a mirror! That kind of transparency!

- High density polyethylene (LDPE) transparency, the equivalent number can reach about 90%, but the temperature should be controlled well, there is no general problem, that is, the cost is higher than other products

- Q: ABS plastic storage conditions

- Plastic materials generally react with light and oxygen for a long time to become yellow and brittle

- Q: What are the raw materials for producing plastic bowls and cups?

- Mostly PP, PE, these two.

- Q: What is the raw material for producing corn starch plastic film?

- According to the current technical level, the production of 1 tons of starch requires 1.5 tons of corn, power consumption of 200KWh, coal consumption of 0.3 tons. If the 1 tons of starch into biomass plastics, can be processed into 1.01.2 tons of products, instead of common plastics, saving petrochemical resources, the country. Because there is no effective stimulating mechanism in the downstream market, the application of corn starch is still limited to the research area of modified starch. The industrialization of biomass plastics with corn starch as the main raw material will effectively stimulate the cultivation of corn and the production of cornstarch. Biomass plastics are gradually evolved from the further research and development of biodegradable plastics. It is gradually recognized that only by fully utilizing the natural and recyclable plant resources to develop and develop biomass plastics is a reliable way to achieve sustainable economic development. In the past 30 years, and in half a century, all countries in the world pay attention to and invest a lot of manpower and material resources of biomass plastics, mainly starch and biodegradable plastics mixing, carbon dioxide copolymer, biosynthesis of biodegradable plastics, and then generate a biosynthetic precursor chemical polymerization of biodegradable plastics in 4 categories. The latter three prices are higher, but the cost is higher, mainly used in medical materials, biomedical engineering and tissue engineering and other high-value products.

- Q: What is the raw material for producing high temperature polyethylene plastic bags?

- Adding nano scale montmorillonite can meet your requirements, forming a nanocomposite of polyethylene montmorillonite.

Send your message to us

Oil Resistant Irradiation Cross-linkable Low Smoke Zero Halogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches