Low Smoke Halogen Free Flame Retardant Polyolefin Jacket Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LSZH compound:

1. competitive price

2. 30 years of experience

3. stable quality

4. customized product

LSZH compound:

1. Applications and cable specifications of LSZH compound:

Common jacket for flame retardant wires and cables which operation temperature is at 90 degree C.

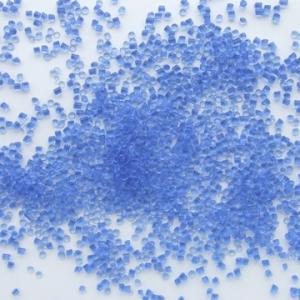

2. Description of LSZH compound:

Thermoplastic, low-smoke, halogen-free and flame retardant POE jacket compound, based on POE resin, is produced and pelletized by special technology with adding special modifier, flame retardant, anti-oxidant and other special additives.

3. Processing of LSZH compound:

The compound can be processed with conventional extruders, and the screw with a minimum 20:1 L/D and a compression ratio of 1.2 is recommended.

The following temperature(°C) profile of extruder is recommended:

| Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

| temperature degree C | 140 | 145 | 150 | 150 | 145 | 145 |

Note:Compound should be dried at 70-80 degree C before use, which has been stored more than two months.

4. Storage and transport of LSZH compound:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

5. Properties of LSZH compound:

| Item | Unit | DW9021 | DW9023 | DW9023B | DW9023C | ||||

| Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | ||

| Density | g/cm3 | -- | 1.46 | -- | 1.48 | -- | 1.5 | -- | 1.5 |

| Hardness | Shore A | -- | 95 | -- | 95 | -- | 95 | -- | 96 |

| Tensile Strength | ≥MPa | 9 | 12.5 | 9 | 12.5 | 9 | 12 | 9 | 10.5 |

| Elongation at Break | ≥ % | 125 | 200 | 125 | 190 | 125 | 230 | 125 | 150 |

| Thermal Aging | degree C * h | 110×240 | 110×240 | 110×240 | 110×240 | ||||

| TS/EB Retention | ≥ % | 75/75 | 105/86 | 75/75 | 110/82 | 75/75 | 104/91 | 75/75 | 115/85 |

| Hot Deformation 80 degree C 4(6)h | ≤ % | 50 | 22 | 50 | 21 | 50 | 24 | 50 | 16 |

| Impact Brittleness Temperature | ≤degree C | -20 | pass | -20 | pass | -20 | pass | -20 | pass |

| Volume Resistivity, at 20 degree C | ≥Ω*m | 1.0×1011 | 1.1×1012 | 1.0×1011 | 2.3×1012 | 1.0×1011 | 1.8×1012 | 1.0×1011 | 2.9×1012 |

| Oxygen Index | ≥ | 33 | 33 | 35 | 36 | 37 | 38 | 38 | 40 |

| Smoke Density Flaming | ≤ | 100 | 66 | 100 | 62 | 100 | 51 | 100 | 54 |

| Non flaming | ≤ | 200 | 135 | 200 | 132 | 200 | 143 | 200 | 125 |

| Acidity of gases evolved (pH) | ≥ | 4.3 | 5.3 | 4.3 | 5.7 | 4.3 | 6.1 | 4.3 | 6.1 |

| Conductivity of gases evolved | ≤μs/mm | 10 | 1 | 10 | 1 | 10 | 1 | 10 | 1 |

| Content of halogen acids | ≤ mg/g | 5 | 1 | 5 | 1 | 5 | 0.9 | 5 | 0.8 |

| Toxicity Index | ≤ | 2.5 | 1.2 | 2.5 | 1.1 | 2.5 | 1.7 | 2.5 | 1 |

| Thermal Impact Test Condition 150 degree C*1h | No cracking | Pass | No cracking | Pass | No cracking | Pass | No cracking | Pass | |

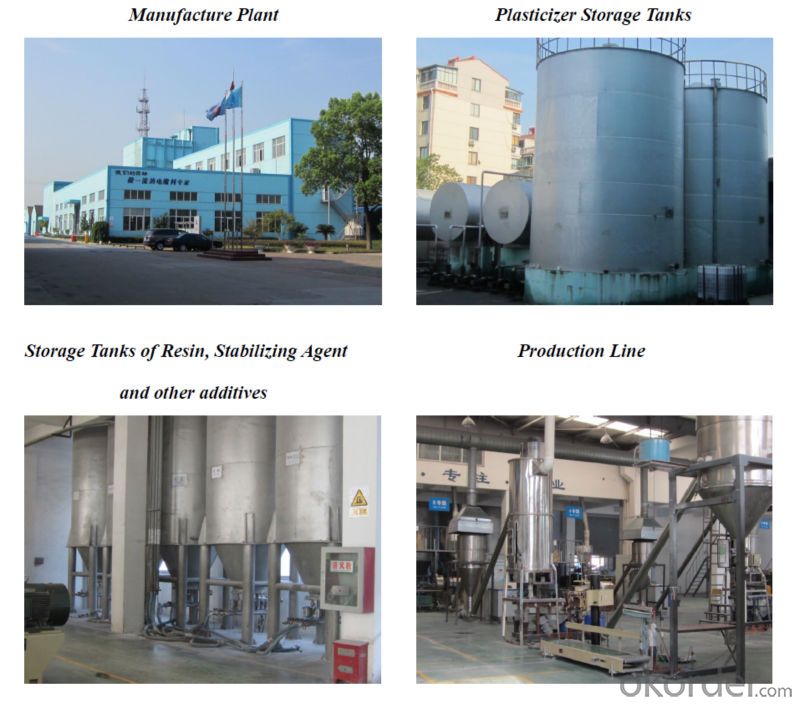

6. Company

- Q: How are plastic products made? What is the raw material of plastics?

- Plastic products are divided into: injection molding, blow molding, spray molding, blister, and die casting. Plastic material is oil. It must be done at a high temperature. The mold you call is usually steel.

- Q: Pollution in the production of plastic raw materials from petroleum production

- Petroleum - intermediate - polymerization monomer - resin - plastic particles - plastic products, the process of the above, each will have pollutants!

- Q: Plastic raw materials, why LDPE and LLDPE?

- LDPE is a low density polyethylene with a large number of branched structures. The molecular structure is lack of regularity, so the crystallinity of LDPE is small, 65%~75%, and the density is low, 0.91~0.93 grams / cubic centimeter. LLDPE is a linear low density polyethylene. Its molecular structure is linear, branched less, branched short, and its density is similar to that of LDPE. Its physical and mechanical properties are better than those of LDPE.

- Q: What are the main raw materials of plastic products?

- ABS plastic (acrylonitrile butadiene styrene) English Name: AcrylonitrileButadiene StyreneSpecific gravity: 1.05 g / cubic centimeter molding shrinkage: 0.4-0.7% molding temperature: 200-240 DEG C, drying conditions: 80-90 hours, 2 hoursThe material performance is 1, the comprehensive performance is better, the impact strength is higher, the chemical stability and the electrical performance are good. It is suitable for making general mechanical parts, reducing wear and wear parts, transmission parts and telecommunications parts

- Q: What is the plastic bag made of?

- The main raw material of plastic bags is polyethylene and polyvinyl chloride, are not biodegradable. The main raw material for the production of plastic bags and polystyrene, polypropylene polymer, waste plastic packaging into the environment, because of its difficult degradation, caused by long-term, deep ecological and environmental problems. In the mixed waste plastic packaging effect of soil, crops absorb nutrients and moisture, will lead to crop failures; abandoned waste plastic packaging on land or in the water, animal as food ingestion, will lead to the death of the animal.

- Q: What are plastic materials extracted from?

- Broadly speaking, any polymer compound that can be used as plastic material for processing raw materials is called resin. Resin is the main raw materials for the manufacture of plastics, paint is also used the system (the main film-forming material, coating such as alkyd resin, acrylic resin, synthetic fatty acid resin, the resin in the Yangtze River Delta and Pearl River Delta are also relatively strong in the paint industry, such as Changxin chemical, Nuplex resin, three resin, Ying DSM syntech resins), adhesives, insulating material, synthetic resin in industrial production, is widely used in separation and purification of impurities in liquid, with macroporous adsorption resin, ion exchange resin, and some special resin.

- Q: Characteristics and uses of CA plastics

- A chemically modified natural polymer obtained by esterification of hydroxyl groups in cellulose molecules with acetic acid. Its performance depends on the degree of acetylation.

- Q: What two ingredients fit together to solidify like plastic?

- Secondly, whether or not the material can be calibrated in accordance with the displacement sensor (or embedded in it), and then the gap distance is measured by reading after installation.

- Q: How about the price of plastic raw materials now?

- ABS market overall stability, part of the small move.

- Q: What are the raw materials for producing plastic films?

- Plastic film raw materials are: PVC, polyethylene, polypropylene, polystyrene and other resins.

Send your message to us

Low Smoke Halogen Free Flame Retardant Polyolefin Jacket Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords