Silane Cross-linkable Low Smoke Zero Halogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Halogen Free flame retardant:

1. competitive price

2. 30 years of experience

3. stable quality

4. customized product

Halogen Free flame retardant:

1. Applications and cable specifications:

General type. Used as cross-likable low smoke halogen free insulation and jacket for electronic wires, cotton coverd wire for construction. Work temperature: -40 to 125 degree C .

2. Description:

Silane crosslinkable low smoke halogen free POE compound, based on POE resin, is produced and pelletized by special technology, adding flame retardant, initiator, crosslinking agent and other special additives. This compound is composed of A materials and B materials, when it is used, please mix the A and B in the proportion of 97:3. This compound has advantage of excellent properties, processing easily, and excellent physical properties, meeting JB/T 10436-2004 standard.

3. Processing:

Equipment: it is recommended that this compound should be processed by professional screw for halogen free compound, with compression ratio of 1.2 to 1.5 (L:D should be 25 to 18). If you use PVC extruder, the speed should be lower and focus on cooling.

The following temperature(degree C) profile of extruder is recommended (temperature here is only for reference, and it will be different according to different extruder and temperature controlling equipment):

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature | 110 | 140 | 160 | 160 | 165 | 170 |

Method of application:

(1) When you use this product, please mix A and B before put into the hopper. If you need color, the cable factory can use the polyvinylene masterbatch. The material should be used up after it opened in 8 hours and the rest can be resealed and usable within 24 hours.

(2) The extruder should be cleaned with PVC material after stopping, (It is preferable if you can take apart the screws to clean.)

(3) The silane crosslinkable LSZH compound should not be stayed in the extruder for a long time .If it stayed for long time, it will pre-crosslink after open the machine, which will make lumps in the surface of cable. It need to be discharged all the pre cross-linker, and then produce the cable properly.

(4) To ensure the safety and fully of the cross-linking, when immersed the compound into the hot water or steam, please calculate the cross-linking time based on the terms of more than 85℃, 8h/mm thickness cross-linking speed.

(5) At room temperature, the degree of crosslinking can also meet requirements after 7-10 days. The specific time can be different according to the temperature and humidity.

Note:

(1) Transportation: avoid direct sunlight and weathering and machine damage

(2) Convey: discharge softly, put off softly, avoid from the bursting by the stressed with the aluminum-plastic Bag.

(3) Storage: it can not be landing stack. It should be put on the pallet in the clean dry storage.

(4) Keep dry: When the material used, it must not be contained the outer water. Otherwise, it will seriously pre-crosslink.

(5) Quality guarantee period: 6 months after manufacturing.

4. Storage and transport:

Packaging:25kg/bag, Aluminum foil and PE film bag inside, and Kraft bag outside.

Storage and transport: Avoiding in direct sunlight and weathering. The storage should be clean, cool, dry, and ventilated.

5. Properties:

NO. | Item | Unit | GDW125A | GDW125C | GDW125H | |||

Standard | Typical | Standard | Typical | Standard | Typical | |||

1 | Density | g/cm3 | — | 1.44 | — | 1.38 | — | 1.43 |

2 | Tensile strength | MPa | ≥10 | 14.1 | ≥10 | 11.0 | ≥10 | 13.1 |

3 | Elongation at break | % | ≥150 | 240 | ≥150 | 230 | ≥150 | 230 |

4 | Hardness | Shore A | — | 97 | — | 91 | — | 97 |

5 | Thermal aging |

|

|

|

|

|

|

|

Condition: temperature | 158℃ |

|

|

|

|

|

| |

Time | 168h |

|

|

|

|

|

| |

TS retention | % | ≤±30 | -10 | ≤±30 | -12 | ≤±30 | -10 | |

EB retention | % | ≤±30 | -13 | ≤±30 | -10 | ≤±30 | -8 | |

6 | Thermal prolongation 200℃,0.2MPa,15min |

|

|

|

|

|

|

|

Elongation under load | % | ≤175 | 70 | ≤175 | 80 | ≤175 | 65 | |

Permanent deformation | % | ≤15 | 0 | ≤15 | 0 | ≤15 | 0 | |

7 | Volume Resistivity, at 20 degree C | Ω·m | ≥1.0×1012 | 2.3×1013 | ≥1.0×1012 | 2.0×1013 | ≥1.0×1012 | 2.1×1013 |

8 | Dielectric strength | MV/m | ≥20 | 28 | ≥20 | 28 | ≥20 | 29 |

9 | Resistance to thermal stress crack | h | ≥96 | pass | ≥96 | pass | ≥96 | pass |

10 | Resistance to environmental stress crack | h | ≥96 | pass | ≥96 | pass | ≥96 | pass |

11 | Oxygen Index |

| ≥30 | 36 | ≥30 | 30 | ≥30 | 36 |

12 | Smoke density flaming |

| ≤100 | 50 | ≤100 | 60 | ≤100 | 50 |

Non flaming |

| — | 130 | — | 150 | — | 120 | |

13 | Burst Size of HCL | mg/g | ≤5 | 0 | ≤5 | 0 | ≤5 | 0 |

14 | PH value |

| ≥4.3 | 6.7 | ≥4.3 | 6.5 | ≥4.3 | 6.3 |

15 | Conductivity | μS/mm | ≤10 | 0.8 | ≤10 | 0.6 | ≤10 | 0.9 |

16 | Toxicity Index |

| ≤3 | 1.2 | ≤5 | 1.3 | ≤5 | 1.3 |

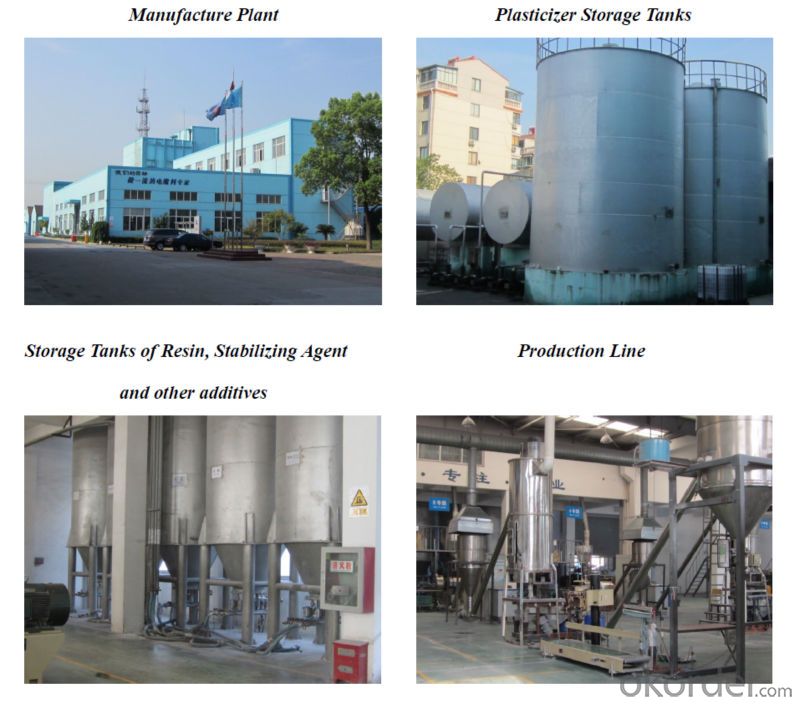

6. Company

- Q: How many types of plastics are there?

- PU Name: polyurethane (foam). Mainly used for handrail accessories.Name: POM steel is mainly used for wear parts such as mats, casters, door hinge, hinge and so on. The performance of wear resistance, pressure resistance, but poor dimensional stability.Name: PA nylon. Mainly used as foot, claw, wheel wear, the life of high demand place. Features: wear resistance, pressure resistance, high strength and long service life of indoor, individual models such as PA66 heat up to 2200, is easy to change, easy to break the drying performance, poor weather resistance in the sun.PMMA: organic glass (commonly known as acrylic). There are five kinds of transparent plastic material, and PMMA is one of the highest transparency, cutting when vinegar sour, easy deformation, can turn plastic soaked in boiling water. Disadvantages: easy to scratch the surface, low hardness, easy to crack when bending, the price is higher than ABS more than 20%.

- Q: The difference between resin and plastics

- Resin material: it is natural, extracted from plants, the cost is higher. Plastic: it is chemical material, extracted from petroleum, Chen is lower

- Q: What are the APP of plastic raw materials?

- Thermosetting plastics (phenolics, epoxy resins, unsaturated polyesters, polyurethanes, silicones, amino resins, etc.);

- Q: What are the raw materials for plastic products? Resin or oil?

- General Plastics: - General refers to large output, wide use, good formability, low price plastic. Such as polyethylene, polypropylene, PVC and so on.Engineering Plastics: - General refers to the ability to withstand certain external force, and has good mechanical properties and dimensional stability, high and low temperatures can still maintain its good performance, can be used as plastic parts of Engineering structures. Such as ABS, nylon, poly alum and so on.Special plastics: - General refers to special functions (such as heat resistance, self-lubricating, etc.), applied to special requirements of plastics. Such as fluorine plastics, silicone and so on.

- Q: What are the plastic raw materials?

- 1, general plastics (polyethylene, polypropylene, polyvinyl chloride, polystyrene, ABS, etc.), thermosetting plastics (phenolic resin, epoxy resin, unsaturated polyester, polyurethane, silicone, amino resin, etc.);2 thermosetting plastics (phenolic resin, epoxy resin, unsaturated polyester, polyurethane, silicone, amino resin, etc.);3, thermoplastic engineering plastics (polyamide, polycarbonate, POM, PET, PBT and other plastics)

- Q: What raw material (HDPE) made of plastic bags, high transparency, good sense of light master?

- Synthetic resin is the most important component of plastics, and its content in plastics is generally between 40% and 100%. Because of the large amount and the nature of the resin, which often determines the nature of plastics, people often think of resin as a synonym for plastics. For example, PVC resin is mixed with PVC plastic, phenolic resin and phenolic plastics. In fact, resin and plastics are two different concepts. Resin is an unprocessed primitive polymer that is used not only in plastics but also as raw material for paints, adhesives and synthetic fibers. In addition to a very small number of plastic containing 100% of the resin, the vast majority of plastic, in addition to the main component resin, but also need to add other substances

- Q: Does anyone know what kind of plastic material PP-M40 is?

- High gloss PP has high gloss, high fluidity, heat resistance, medium impact toughness and fine processability. The utility model is suitable for making household appliances (rice cookers, vacuum cleaners, electric irons, etc.), office equipment, instruments and meters, beauty equipment, etc..

- Q: What are the heavy bags in the plastic material?

- (polypropylene) English Name: Polypropylene, PP plastic concept, proportion polypropylene, also includes propylene and a small amount of ethylene copolymer. PP granular material is natural, cylindrical particles, smooth particles

- Q: What are the raw materials made of modified plastics?

- In order to reduce costs, improve performance and meet different needs, plastics are often modified to suit a variety of practical requirements. Commonly used methods are mainly:1. filling modification, adding a certain amount of filler in plastic is an important way to reduce plastic prices and improve performance. Such as phenolic resin filled with wood and paper made of bakelite practical material, overcomes the weakness of crisp.2. blends of two or more polymers with similar properties and two or more polymers are blended in a certain proportion to make polymer blends.3. copolymerization of two or more than two kinds of monomer polymerization of a copolymer of ethylene propylene rubber, such as copolymerization of ethylene and propylene has a good elasticity; acrylonitrile, butadiene and styrene copolymer obtained with ABS resin.

- Q: What are the bulk density, size and moisture content of the general plastic material?

- The bulk density has something to do with particle size. The larger the particle, the smaller the bulk density of the same composition. This is because the accumulation of material quality, material bulk density = space volume. The bulk density is pseudo density.

Send your message to us

Silane Cross-linkable Low Smoke Zero Halogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches